-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

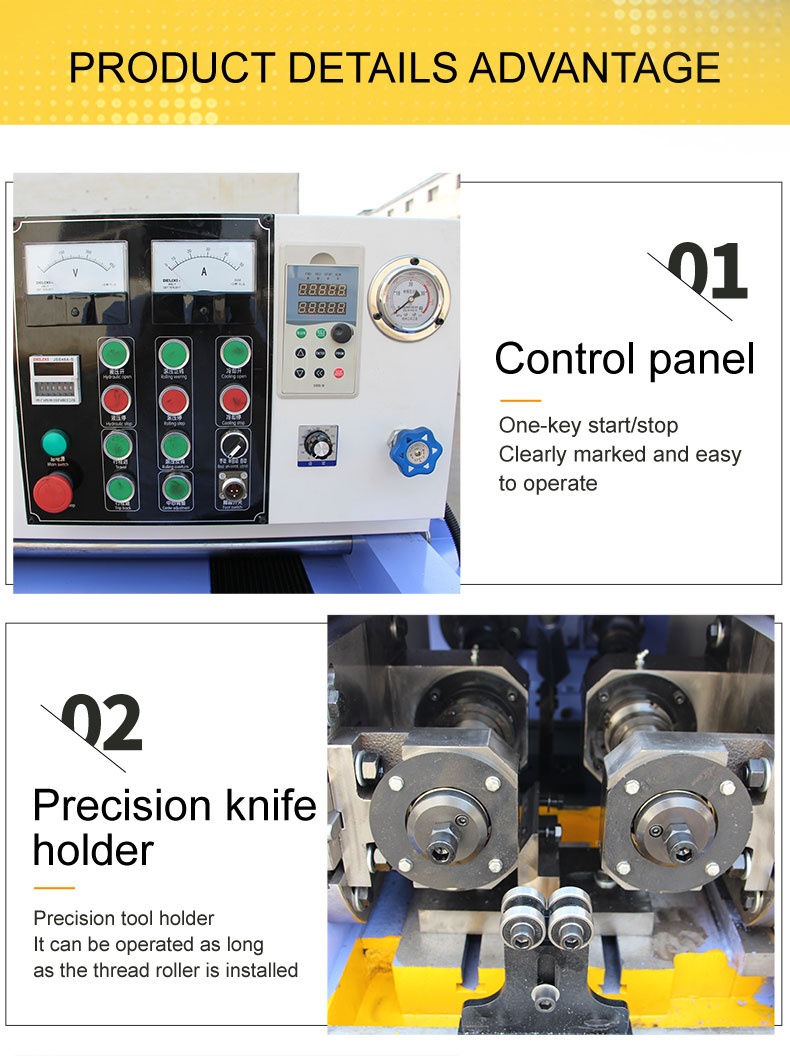

Premium Flat Thread Rolling Machines for Enhanced Precision and Efficiency

The Importance of High-Quality Flat Thread Rolling Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, the need for precision and efficiency can't be overstated. Industries across the globe are constantly seeking ways to improve their production processes, reduce waste, and increase the overall quality of their products. One critical piece of equipment that plays a significant role in this quest for excellence is the flat thread rolling machine. This article will delve into the importance, benefits, and advancements of high-quality flat thread rolling machines in modern manufacturing.

Understanding Flat Thread Rolling Machines

Flat thread rolling machines are specialized equipment used to produce threads on metal parts. The process involves the cold forming of threads onto a flat surface, which results in high tensile strength and durability due to the material being work-hardened during the rolling process. This method is not only efficient but also produces superior quality threads compared to traditional cutting methods.

Benefits of High-Quality Flat Thread Rolling Machines

1. Precision Engineering High-quality flat thread rolling machines are engineered to deliver exceptional accuracy and consistency. This precision is crucial in industries such as automotive, aerospace, and construction, where even the smallest deviation can lead to significant issues in performance and safety.

2. Cost-Effectiveness Investing in high-quality machinery often pays off in the long run. Flat thread rolling machines reduce material wastage and minimize the need for secondary operations. This efficiency translates into lower production costs and higher profit margins for manufacturers.

3. Increased Production Speed Time is money in manufacturing. Flat thread rolling machines can operate at high speeds, enabling manufacturers to increase their output without compromising on quality. This capability allows companies to meet tight deadlines and respond quickly to market demands.

4. Enhanced Product Strength The rolling process imparts compressed grain structure and increases the hardness of the threads, resulting in parts that are not only stronger but also more resistant to wear and fatigue. This quality is vital in applications where reliability is paramount.

high quality flat thread rolling machine

5. Versatility Modern flat thread rolling machines are designed to handle a variety of materials, including different grades of steel, aluminum, and even some plastics. This versatility allows manufacturers to adapt to changing production requirements and market trends seamlessly.

Technological Advancements

Recent advancements in technology have revolutionized flat thread rolling machines. The integration of computer numerical control (CNC) technology has allowed for greater flexibility and automation. CNC flat thread rolling machines can be programmed to produce complex thread profiles with minimal human intervention. This programming capability not only enhances productivity but also maintains high standards of quality.

Additionally, the introduction of smart monitoring systems enables real-time tracking of machine performance and product quality. These systems provide valuable data that can be used to optimize production processes, reduce downtime, and predict maintenance needs. As a result, manufacturers can ensure that their operations run smoothly and efficiently.

Environmental Considerations

High-quality flat thread rolling machines are also designed with sustainability in mind. The cold forming process generates significantly less waste compared to traditional machining methods. Moreover, many modern machines are equipped with energy-efficient features that reduce power consumption. This aligns with the global push for more sustainable manufacturing practices and minimizes the environmental impact of industrial processes.

Conclusion

In conclusion, high-quality flat thread rolling machines are integral to modern manufacturing. Their ability to produce precise, strong, and cost-effective threaded components makes them indispensable in various industries. As technology continues to advance, the capabilities of these machines will only improve, providing manufacturers with the tools they need to remain competitive in an ever-evolving market. By investing in high-quality flat thread rolling machines, companies can enhance their productivity, reduce costs, and contribute to a more sustainable future in manufacturing. The right machinery can pave the way for innovation, efficiency, and success in an increasingly demanding industrial landscape.