-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

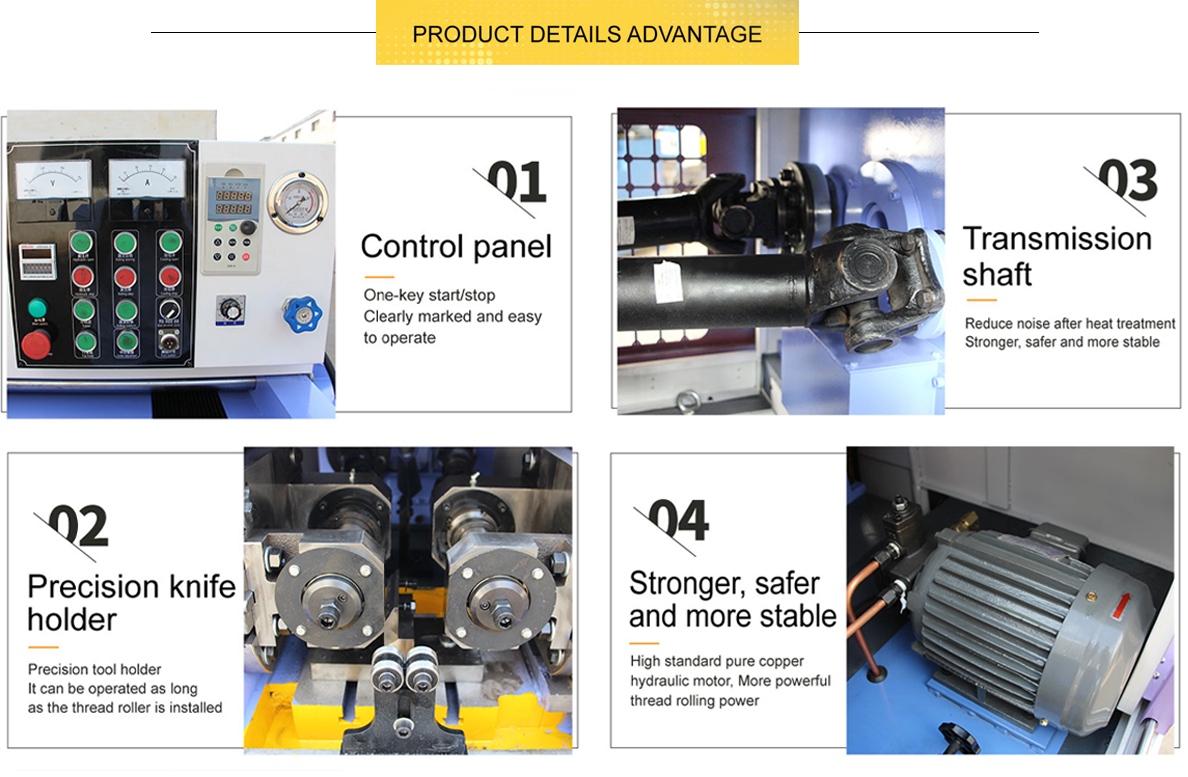

Types of Manufacturers for Thread Rolling Machines and Their Applications

Types of Thread Rolling Machine Manufacturers

In the world of manufacturing, the precision and quality of threaded components are crucial. Thread rolling machines play a vital role in producing these components, offering significant advantages over traditional cutting methods. Manufacturers around the globe specialize in producing these machines, each with unique features and technologies that cater to diverse industrial needs.

One of the primary types of thread rolling machines is the flat die thread rolling machine. This type uses flat dies to create threads on the workpiece as it passes through. These machines are known for their efficiency and are particularly suitable for producing large quantities of threaded components. Manufacturers specializing in this type often emphasize high production rates and the ability to handle different material types, including steel and aluminum.

Another significant category is the cylindrical thread rolling machine. This machine utilizes cylindrical dies and is ideal for creating threads on round bars. It is particularly favored in the automotive and aerospace industries, where precision is paramount. Manufacturers of cylindrical machines often focus on advanced technology, integrating CNC (Computer Numerical Control) systems to enhance accuracy and automation in the production process.

types of thread rolling machine manufacturer

Multi-station thread rolling machines represent another innovative approach in the industry. These machines feature multiple rolling stations that allow for simultaneous processing of several components. This design greatly increases production efficiency and is particularly beneficial for manufacturers who need to meet high demand. The manufacturers of multi-station machines often highlight their customizable solutions, catering to clients with specific production requirements.

It's also worth mentioning specialized thread rolling machines, which are tailored for unique applications. For instance, some manufacturers design machines specifically for producing threads on non-standard shapes or for industries that require specific thread profiles, such as medical device manufacturing. These specialized machines demonstrate the adaptability within the thread rolling machine market, showcasing manufacturers' ability to meet niche market needs.

When choosing a thread rolling machine manufacturer, several factors come into play. Quality assurance, after-sales service, and the availability of spare parts are paramount. Buyers should also consider the manufacturer's reputation and their experience in the industry, as these aspects often translate into the reliability and longevity of the machines.

In conclusion, the landscape of thread rolling machine manufacturers is diverse, with options ranging from flat die to specialized machines. Each type offers unique benefits and is suited for different manufacturing needs. As industries continue to evolve, these manufacturers are poised to innovate further, ensuring that they meet the demands of modern production processes. Selecting the right manufacturer can significantly impact production efficiency, quality, and overall operational success.