-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

англійская

англійская -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

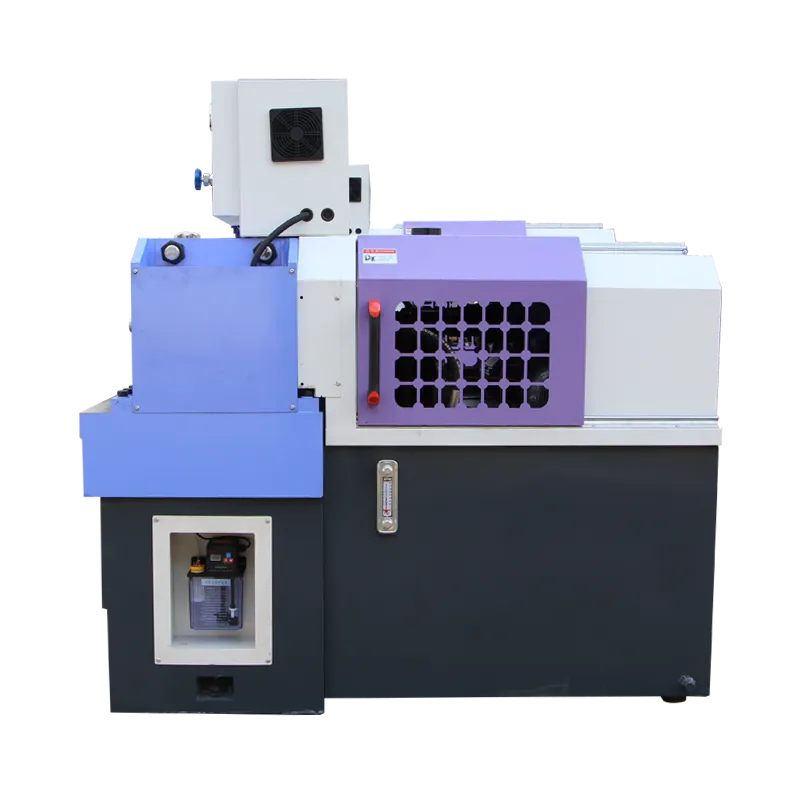

Improving Manufacturing Precision: Advantages of Automated Thread Rolling Machines

In the modern manufacturing industry, precision and efficiency are crucial for producing high-quality threaded components. Whether you're looking for an automatic thread rolling machine, a thread rolling tool, or a flat die thread rolling machine, these machines have become an indispensable part of the production process. With their ability to create durable, high-quality threads, thread rolling machines are a must-have for many industries, including automotive, aerospace, and machinery production. This advertrial will explore the benefits of these machines, focusing on the automatic thread rolling machine, thread rolling tool, flat die thread rolling machine, and small thread rolling machine.

The Automatic Thread Rolling Machine: A Game Changer in Manufacturing

An automatic thread rolling machine is revolutionizing the way manufacturers approach the threading process. By automating the entire operation, this machine enhances productivity and efficiency, allowing businesses to meet the growing demand for high-quality threaded components. The automatic thread rolling machine offers a level of precision that manual methods simply cannot match, ensuring that threads are formed with consistency and accuracy every time.

The use of an automatic thread rolling machine significantly reduces human error, which in turn improves the overall quality of the threaded components. In addition to its high precision, this machine can operate at faster speeds, producing larger volumes of threaded components in less time. This makes it a great choice for businesses looking to increase production rates without compromising on quality.

Moreover, the automatic thread rolling machine is designed to be user-friendly. With programmable controls and automatic settings, operators can easily adjust the machine to produce different types of threads, reducing the time spent on setup and maintenance. This flexibility makes the automatic thread rolling machine an essential tool for businesses with diverse production needs.

By investing in an automatic thread rolling machine, manufacturers can achieve greater efficiency, reduce production costs, and improve the overall quality of their threaded products. This machine is particularly useful for industries that require high-volume production, such as automotive manufacturing, where precision and speed are paramount.

The Thread Rolling Tool: The Essential Companion for Thread Rolling Machines

A thread rolling tool is an integral part of any thread rolling process. These tools are designed to be used with thread rolling machines, enabling the creation of threads on workpieces with remarkable precision. The thread rolling tool comes in various shapes and sizes to accommodate different types of thread rolling machines and threaded components.

The primary function of the thread rolling tool is to apply pressure to the material, which deforms it to create threads. This process is different from traditional cutting methods, as it involves pushing the material to form the threads rather than removing material. This not only improves the strength of the threads but also provides a smoother surface finish.

Using a thread rolling tool allows manufacturers to create threads that are stronger and more durable than those produced through other methods. The tool works by aligning the material’s grain structure, making the threads resistant to wear and tear. This is particularly important for industries that produce components subject to high stress, such as automotive and aerospace industries.

Investing in high-quality thread rolling tools is essential for ensuring the efficiency and longevity of thread rolling machines. These tools are designed for easy replacement and maintenance, allowing businesses to keep their production lines running smoothly. Whether you're working with metals, plastics, or other materials, the thread rolling tool plays a crucial role in producing high-quality threaded components.

Flat Die Thread Rolling Machine: The Ideal Solution for External Threading

The flat die thread rolling machine is one of the most widely used machines in the thread rolling industry, particularly for producing external threads. This machine works by applying pressure to the workpiece with two flat dies, which form the threads. The flat die thread rolling machine is a versatile and cost-effective solution for high-volume production, especially for manufacturers looking to produce external threads in a quick and efficient manner.

One of the key advantages of the flat die thread rolling machine is its ability to handle large quantities of components in a short amount of time. The machine operates at high speeds, reducing the overall time spent on the threading process. This makes it an ideal choice for businesses that need to produce large batches of threaded components quickly, such as fasteners and bolts.

The flat die thread rolling machine is also known for its precision and ability to create uniform threads. By using this machine, manufacturers can ensure that every threaded component meets the required specifications and tolerances. The result is a high-quality finished product with consistent thread depth, pitch, and form.

In addition to its speed and precision, the flat die thread rolling machine is easy to maintain and operate. The machine’s simple design and user-friendly controls make it accessible to operators with varying levels of experience. For businesses that require high-volume production and external threading, the flat die thread rolling machine is an essential tool in the manufacturing process.

Small Thread Rolling Machine: Compact Yet Powerful

For businesses with limited space or smaller production runs, the small thread rolling machine offers a compact yet powerful solution. This machine is designed to deliver the same precision and quality as larger machines, but in a smaller, more space-efficient package. The small thread rolling machine is ideal for businesses that need to produce small quantities of threaded components without sacrificing quality or performance.

Despite its size, the small thread rolling machine is capable of handling a wide range of materials and thread sizes. Whether you're working with metals, plastics, or other materials, this machine can accommodate a variety of threading applications. The small thread rolling machine is particularly useful for businesses that need to create high-precision threads on smaller workpieces, such as medical devices or electronics.

The small thread rolling machine is also highly versatile. It can be easily adjusted to create different types of threads, including internal and external threads. This flexibility makes it a great choice for businesses with diverse production needs. Additionally, the small thread rolling machine is designed for easy maintenance, ensuring that it remains in good working condition for years to come.

For manufacturers looking for an affordable and efficient solution for small-scale thread rolling, the small thread rolling machine is an excellent option. Its compact design, coupled with its high-performance capabilities, makes it a valuable addition to any production line.

Choosing the Right Thread Rolling Machine for Your Business

Selecting the right thread rolling machine is essential for businesses that require precision threading in their manufacturing process. Whether you're interested in the automatic thread rolling machine, thread rolling tool, flat die thread rolling machine, or small thread rolling machine, each type offers unique benefits tailored to different production needs.

An automatic thread rolling machine offers efficiency and precision, making it ideal for high-volume production. Meanwhile, a flat die thread rolling machine is perfect for external threading and is known for its speed and accuracy. For those looking for a more compact solution, the small thread rolling machine provides powerful performance in a smaller package. Additionally, the thread rolling tool is an essential part of the process, helping manufacturers produce high-quality threaded components.

By investing in the right thread rolling machine, businesses can improve production efficiency, reduce costs, and enhance the overall quality of their threaded components. Whether you are looking for a high-speed, high-volume machine or a compact, space-saving option, there is a thread rolling machine that will meet your needs and help your business thrive in the competitive manufacturing industry.