-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ян. . 28, 2025 04:16

Back to list

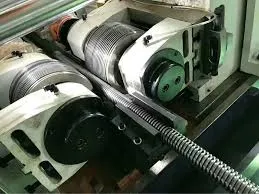

oem pipe thread rolling machine

The OEM pipe thread rolling machine stands at the intersection of innovation, precision engineering, and industrial efficiency. This marvel of modern manufacturing is a pivotal component for industries that demand accuracy and quality in their threaded pipes, such as oil and gas, automotive, plumbing, and construction. Understanding the machine's features and benefits can underscore its transformative impact on production processes, establishing its credibility and authority in the realm of heavy machinery.

Environmental considerations also play a crucial role in the machine's design. The thread rolling process minimizes scrap and involves no hazardous waste, aligning with sustainable manufacturing practices. For industries aiming to reduce their carbon footprint, this aspect enhances the machine's appeal, positioning it not just as an industrial tool, but a partner in eco-friendly initiatives. In terms of experience, manufacturers who integrate OEM pipe thread rolling machines into their production lines report marked improvements in efficiency and product quality. Case studies highlight instances where companies have achieved up to 25% more output while reducing material costs. These real-world applications underscore the machine's ability to deliver tangible benefits, reinforcing its value proposition to potential buyers. Furthermore, OEM providers offer comprehensive training and support, ensuring that clients can utilize the full spectrum of the machine's capabilities. This support network is a testament to the trustworthiness and reliability that these machines provide, reassuring buyers of their investment's long-term viability. To harness the full potential of an OEM pipe thread rolling machine, businesses are advised to focus on regular maintenance and updates. Keeping the equipment in optimal condition not only prolongs its lifespan but also maintains performance levels, safeguarding against defects or inefficiencies. In conclusion, the OEM pipe thread rolling machine embodies a fusion of precision, reliability, and sustainability. Its significance in industries reliant on robust and precise threading cannot be overstated. With its ability to enhance product integrity and contribute to efficient, eco-friendly manufacturing, this machine is a cornerstone for companies aspiring to lead in a competitive marketplace. By investing in such equipment, businesses not only elevate their production capabilities but also affirm their commitment to quality, safety, and environmental stewardship.

Environmental considerations also play a crucial role in the machine's design. The thread rolling process minimizes scrap and involves no hazardous waste, aligning with sustainable manufacturing practices. For industries aiming to reduce their carbon footprint, this aspect enhances the machine's appeal, positioning it not just as an industrial tool, but a partner in eco-friendly initiatives. In terms of experience, manufacturers who integrate OEM pipe thread rolling machines into their production lines report marked improvements in efficiency and product quality. Case studies highlight instances where companies have achieved up to 25% more output while reducing material costs. These real-world applications underscore the machine's ability to deliver tangible benefits, reinforcing its value proposition to potential buyers. Furthermore, OEM providers offer comprehensive training and support, ensuring that clients can utilize the full spectrum of the machine's capabilities. This support network is a testament to the trustworthiness and reliability that these machines provide, reassuring buyers of their investment's long-term viability. To harness the full potential of an OEM pipe thread rolling machine, businesses are advised to focus on regular maintenance and updates. Keeping the equipment in optimal condition not only prolongs its lifespan but also maintains performance levels, safeguarding against defects or inefficiencies. In conclusion, the OEM pipe thread rolling machine embodies a fusion of precision, reliability, and sustainability. Its significance in industries reliant on robust and precise threading cannot be overstated. With its ability to enhance product integrity and contribute to efficient, eco-friendly manufacturing, this machine is a cornerstone for companies aspiring to lead in a competitive marketplace. By investing in such equipment, businesses not only elevate their production capabilities but also affirm their commitment to quality, safety, and environmental stewardship.

Share:

Latest news

Thread Rolling Machine: A Critical Tool for Industrial Metal Forming

NewsMay.06,2025

Thread Rolling Machine Suppliers

NewsMay.06,2025

Scaffolding Pipe Thread Rolling Machine

NewsMay.06,2025

Hydraulic Thread Rolling Machine Manufacturers

NewsMay.06,2025

High Speed Thread Rolling Machine

NewsMay.06,2025

Automatic Thread Rolling Machine

NewsMay.06,2025