-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

engleski

engleski -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

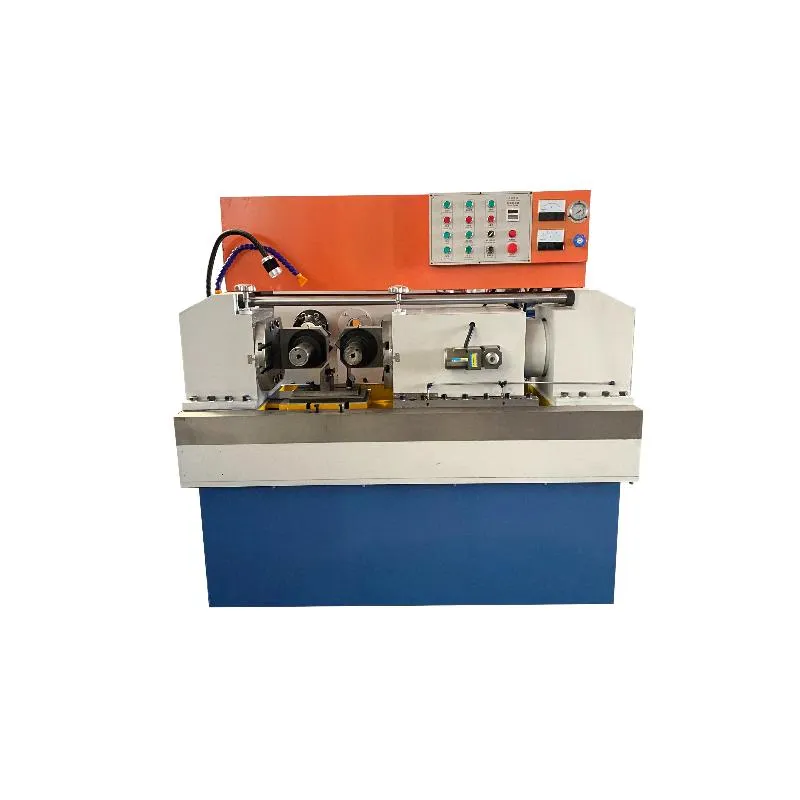

Thread Rolling Machines: Setup, Working, And Pricing Explained

In the world of manufacturing, thread rolling machines are indispensable tools for creating precise and durable threads. Whether you’re curious about the thread rolling machine setup, want to watch a thread rolling machine video, understand the thread rolling machine working process, explore the thread rolling machine price list, or learn about the types of thread rolling, this guide covers it all. From beginners to seasoned professionals, this comprehensive overview will help you make informed decisions and optimize your production process. Let’s dive into the fascinating world of thread rolling machines and discover how they can transform your manufacturing operations.

Mastering the Thread Rolling Machine Setup

Setting up a thread rolling machine correctly is the first step toward achieving high-quality threads. The thread rolling machine setup process involves several key steps, including selecting the right dies, adjusting the machine settings, and ensuring proper alignment. A well-executed setup ensures smooth operation, minimizes material waste, and delivers consistent results.

The thread rolling machine setupbegins with choosing the appropriate dies for the type of thread you want to produce. Dies come in various shapes and sizes, depending on the thread profile and material. Once the dies are selected, they are mounted onto the machine, and the alignment is carefully checked to ensure precision. Next, the machine settings, such as feed rate and pressure, are adjusted to match the material and thread specifications. Finally, a test run is conducted to verify that the setup is correct and the threads meet the desired quality standards.

By mastering the thread rolling machine setup, you can maximize the efficiency and accuracy of your threading process. Whether you’re a beginner or an experienced operator, taking the time to set up the machine properly is essential for achieving optimal results.

Watch and Learn: Thread Rolling Machine Video

For those who prefer visual learning, a thread rolling machine video can be an invaluable resource. These videos provide a step-by-step demonstration of the machine’s operation, from setup to threading and maintenance. Watching a thread rolling machine video allows you to see the process in action, making it easier to understand the intricacies of thread rolling.

A thread rolling machine video typically covers key aspects such as die selection, machine setup, threading techniques, and troubleshooting common issues. Many videos also include tips and best practices from industry experts, helping you optimize your production process. Whether you’re new to thread rolling or looking to refine your skills, a thread rolling machine video offers practical insights that you can apply in your own operations.

In addition to instructional videos, many manufacturers and suppliers provide thread rolling machine videos showcasing their products. These videos highlight the features and capabilities of different machines, helping you make an informed decision when purchasing equipment. By leveraging the power of visual learning, you can enhance your knowledge and skills in thread rolling.

Understanding the Thread Rolling Machine Working Process

The thread rolling machine working process is a fascinating blend of precision engineering and mechanical force. Unlike traditional threading methods that cut material, thread rolling uses cold-forming techniques to shape threads. This process not only enhances the strength and durability of the threads but also reduces material waste, making it a cost-effective solution for manufacturers.

The thread rolling machine working process begins with feeding the workpiece into the machine. The dies, which are shaped to match the desired thread profile, apply pressure to the workpiece, displacing the material to form the threads. This cold-forming process creates threads with superior surface finish and structural integrity. The machine’s high-speed capabilities allow for efficient production, making it ideal for high-volume applications.

One of the key advantages of the thread rolling machine working process is its ability to handle a wide range of materials, from soft metals like aluminum to tough alloys like stainless steel. Additionally, the process produces threads with excellent fatigue resistance, making them suitable for critical applications in industries like automotive, aerospace, and construction. By understanding the thread rolling machine working process, you can appreciate the technology behind this innovative threading method.

Exploring the Thread Rolling Machine Price List

When investing in a thread rolling machine, understanding the thread rolling machine price list is essential for budgeting and decision-making. The price of these machines can vary widely depending on factors like capacity, features, and brand reputation. While it may be tempting to opt for the cheapest option, it’s important to consider the long-term value and performance of the machine.

A high-quality thread rolling machine offers numerous advantages, including superior precision, durability, and efficiency. These machines are designed to handle tough materials and high-volume production, making them a worthwhile investment for industries like automotive, aerospace, and construction. While the upfront cost may be higher, the long-term benefits in terms of productivity and cost savings often outweigh the initial expense.

To get the best deal, it’s advisable to compare the thread rolling machine price list from multiple manufacturers and suppliers. Look for machines that offer the right balance of features, performance, and affordability. By doing so, you can ensure that you’re making a smart investment that delivers lasting value.

Discover the Different Types of Thread Rolling

Thread rolling is a versatile process that can be performed using various techniques, each suited to specific applications. Understanding the types of thread rolling can help you choose the right method for your production needs. The most common types of thread rolling include flat die, cylindrical die, and planetary thread rolling.

Flat die thread rolling is ideal for producing long threads or threads on large-diameter work pieces. This method uses flat dies to form threads, offering excellent control over the threading process. Cylindrical die thread rolling, on the other hand, is well-suited for producing threads on round components like bolts and screws. This method uses circular dies to create uniform threads with high precision.

Planetary thread rolling is a specialized technique used for producing threads on complex or irregularly shaped work pieces. This method involves rotating the work piece around a central die, allowing for precise thread formation. By exploring the different types of thread rolling, you can select the method that best meets your production requirements.

Elevate Your Production with Thread Rolling Machines

In conclusion, mastering the thread rolling machine setup, watching a thread rolling machine video, understanding the thread rolling machine working process, exploring the thread rolling machine price list, and discovering the types of thread rolling are all essential steps in optimizing your production process. Each of these aspects plays a crucial role in ensuring that you get the most out of your thread rolling machine.

By investing in high-quality equipment and leveraging the right techniques, you can achieve precise, durable, and cost-effective threads for a wide range of applications. Whether you’re threading fasteners, pipes, or specialized components, thread rolling machines offer unmatched efficiency and versatility. Don’t miss out on the opportunity to enhance your manufacturing capabilities—explore the world of thread rolling machines today and take your production to new heights.