-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

roll thread machine manufacturers

The Rise of Roll Thread Machine Manufacturers A Comprehensive Overview

The manufacturing industry has witnessed remarkable advancements in technology over the past few decades. Among these innovations, roll thread machines have emerged as a pivotal tool for enhancing productivity and precision in the production of threaded components. This article delves into the significance of roll thread machine manufacturers, the technology behind these machines, and the future of this essential segment of the manufacturing sector.

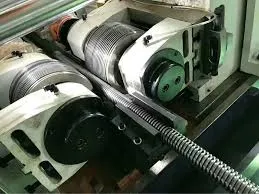

Understanding Roll Thread Machines

Roll thread machines are specialized equipment designed to create threads on metal parts through a cold forming process. Unlike traditional machining methods that involve cutting away material to create threads, roll threading uses high-pressure rollers to deform the metal, forging the threads without removing material. This process not only maintains the integrity of the metal but also enhances its strength, making the final product more durable and reliable.

One of the key advantages of roll threading is its efficiency. The cold forming process allows for faster production rates compared to traditional thread cutting methods, reducing the cycle time and increasing overall output. Moreover, roll thread machines are capable of producing threads with tighter tolerances, making them ideal for applications in industries such as automotive, aerospace, and construction, where precision is paramount.

The Role of Manufacturers

As the demand for high-quality threaded components continues to grow, the role of roll thread machine manufacturers becomes increasingly critical. These manufacturers are responsible for designing, producing, and maintaining roll threading machines that meet the needs of various industries. They invest in research and development to innovate and improve machine capabilities, ensuring that their offerings remain competitive in a rapidly evolving market.

Leading roll thread machine manufacturers are constantly exploring new materials and technologies to enhance the performance and efficiency of their machines. For instance, modern roll thread machines often incorporate advanced features such as CNC (computer numerical control) systems, which allow for greater automation, improved precision, and easier programming. This technological integration not only streamlines the manufacturing process but also reduces the likelihood of human error.

roll thread machine manufacturers

Key Players in the Market

The market for roll thread machines is populated by several notable manufacturers, each contributing to the development of this technology. Companies such as Boma Co., Kern Microtechnik, and Schmid & Wezel have established themselves as leaders in the industry, offering high-quality machines that cater to a range of applications. These manufacturers emphasize quality, efficiency, and innovation, providing their customers with reliable solutions to meet their specific threading needs.

In addition to established manufacturers, the rise of smaller, specialized companies has also been observed. These companies often focus on niche markets or offer custom solutions, providing flexibility and personalized service that larger manufacturers may not be able to match. The diversity of suppliers in the roll thread machine market promotes competition, driving innovation and ensuring customers can find machines that meet their exact specifications.

Challenges and Future Trends

While the roll thread machine manufacturing sector is thriving, it is not without its challenges. Manufacturers must navigate fluctuating material costs, supply chain disruptions, and an increasingly competitive landscape. Furthermore, the push towards sustainability and eco-friendly manufacturing practices is prompting manufacturers to rethink their processes and materials.

Looking to the future, the integration of Industry 4.0 concepts—such as the Internet of Things (IoT) and artificial intelligence (AI)—is likely to transform the roll thread machine landscape. Smart machines capable of self-monitoring and predictive maintenance could significantly reduce downtime and enhance productivity.

Conclusion

Roll thread machine manufacturers play a vital role in the modern manufacturing landscape, providing essential equipment that enables the production of high-quality threaded components. As technology continues to evolve, these manufacturers must adapt to new challenges and embrace innovative solutions to meet the ever-changing demands of their customers. With a commitment to quality and efficiency, roll thread machine manufacturers are poised to remain integral players in the manufacturing industry for years to come.