-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

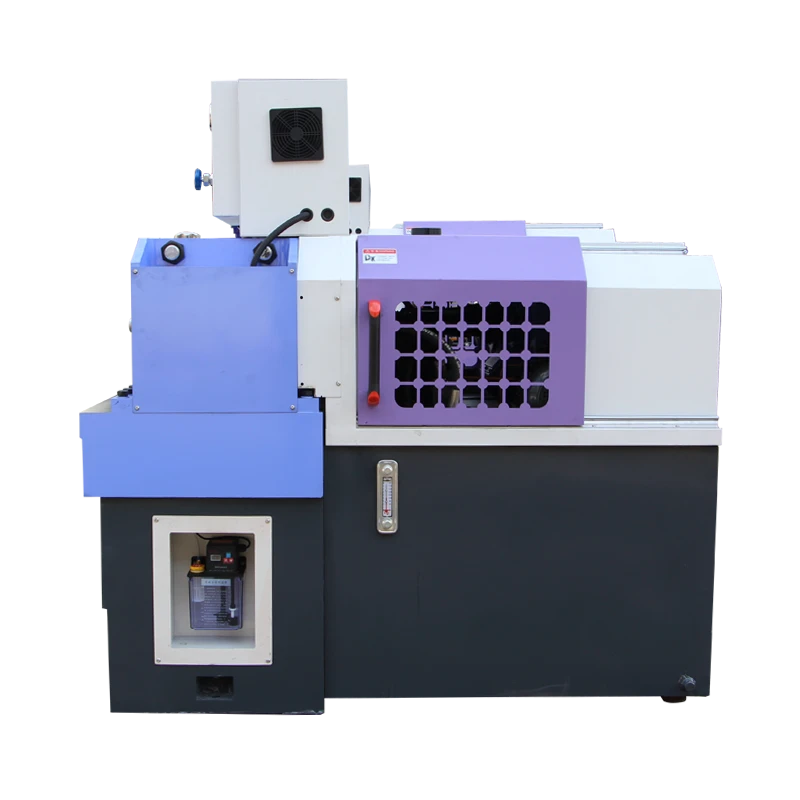

Affordable roller threading machines for efficient and precise industrial applications

The Benefits and Features of Cheap Roller Threading Machines

In the realm of industrial manufacturing and construction, the need for efficient and high-quality threading solutions is paramount. One type of equipment that has gained popularity for its efficiency and cost-effectiveness is the cheap roller threading machine. These machines play a crucial role in various applications, from creating threaded pipes to producing bolts and screws. In this article, we’ll explore what roller threading machines are, their benefits, and why opting for a more affordable version can still deliver the performance you need.

Understanding Roller Threading Machines

Roller threading machines are specialized pieces of machinery designed to create external threads on metal workpieces. Unlike traditional tapping methods, which often involve cutting threads, roller threading uses a process known as thread rolling. This technique involves deforming the metal through pressure, creating threads without removing material from the workpiece. The result is stronger, more resilient threads that can withstand greater stress and wear.

Advantages of Roller Threading Machines

1. Enhanced Strength and Durability Because roller threading creates threads through deformation rather than cutting, the grain structure of the metal is preserved. This leads to a stronger component that exhibits higher fatigue resistance, making it ideal for high-stress applications.

2. Higher Production Rates Roller threading machines can produce threads much faster than traditional methods. This speed increase is due to the efficient nature of the rolling process, which can handle multiple workpieces simultaneously, significantly boosting output.

3. Cost Efficiency While some roller threading machines can be expensive, opting for a cheap roller threading machine does not necessarily mean compromising on quality. Many affordable options are designed to provide excellent functionality without breaking the bank. Reduced costs can be crucial for businesses looking to optimize their operations while maintaining budget constraints.

4. Reduced Material Waste Since threading is achieved through deformation, roller threading produces less scrap material compared to cutting methods. This reduction in waste is not only environmentally friendly but also contributes to cost savings over time.

5. Versatility Cheap roller threading machines can be used for various applications across different industries. They are suitable for threading a wide range of materials, including steel, aluminum, and other alloys. This versatility makes them a valuable addition to any workshop or manufacturing facility.

cheap roller threading machine

6. Ease of Operation Many modern roller threading machines come equipped with user-friendly controls and automation features, making them easy to operate, even for individuals without extensive machining experience. This accessibility can help companies train employees quickly and reduce downtime.

7. Compact Design Affordable roller threading machines often come in compact designs that save space in a workshop setting. This benefit can be crucial for small businesses with limited floor space, allowing them to incorporate essential machinery without overwhelming their workspace.

Choosing the Right Cheap Roller Threading Machine

When looking for a cost-effective roller threading machine, it is essential to consider several factors

- Specifications Evaluate the machine's specifications to ensure it meets your production requirements. Check for the maximum thread size and the materials it can work with.

- Brand Reputation Research the brand and manufacturer of the machine. Established brands often provide better support, warranties, and parts availability, which can be crucial for maintaining machinery in the long run.

- Customer Reviews Look for user feedback on the performance and reliability of the machine. Reviews can provide insight into real-world applications and help you make an informed decision.

- Warranty and Support Ensure that the machine comes with a decent warranty period and consider the availability of customer support. This safety net can provide peace of mind in case of mechanical issues.

Conclusion

In summary, cheap roller threading machines offer a myriad of benefits, including enhanced strength, higher production rates, and cost efficiency. These machines occupy a vital niche in the manufacturing landscape, catering to businesses seeking to streamline their operations without sacrificing quality. By carefully selecting a suitable machine based on your specific needs and budget, you can harness the advantages of roller threading technology while keeping costs under control. Whether you are in construction, fabrication, or any other industry requiring threaded components, investing in a roller threading machine can prove to be a wise decision for your business's success and productivity.