-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

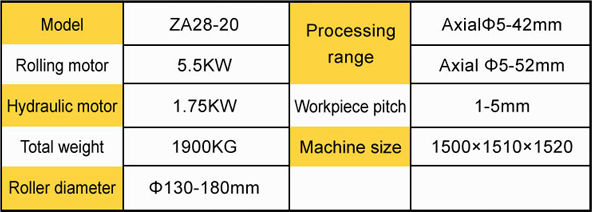

Purchase Circular Thread Rolling Machines for Efficient Metal Processing Solutions

Exploring the Benefits of Buying a Circular Thread Rolling Machine

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency continues to rise. One machine that has gained significant attention for its versatility and effectiveness is the circular thread rolling machine. If you're considering investing in this equipment, understanding its benefits can help you make an informed decision.

What is a Circular Thread Rolling Machine?

A circular thread rolling machine is designed to create threads on various materials, primarily metal, by rolling them under high pressure. This makes it an essential tool in industries such as automotive, aerospace, and construction, where high-strength components with precise dimensions are crucial.

Precision and Consistency

One of the standout advantages of using a circular thread rolling machine is the precision it offers. Traditional cutting methods can lead to material wastage and inaccuracies, while thread rolling preserves the material integrity. This method produces exceptionally strong threads with tight tolerances, ensuring that each component meets quality standards. The consistency achieved with this machine minimizes the need for post-processing, thereby streamlining production workflows.

Cost-Effectiveness

buy circular thread rolling machine

Investing in a circular thread rolling machine can lead to significant cost savings over time. By reducing material waste and the need for extensive finishing operations, companies can lower production costs. Additionally, the durability of the threads produced minimizes the likelihood of failures in the final products, which can be costly due to recalls or replacements.

Versatility in Application

Circular thread rolling machines are highly versatile. They can be used for various applications, including creating threads on bolts, screws, and other fasteners. The ability to work with different materials, including hard metals, makes this machine suitable for a wide range of industries. Whether you are manufacturing small-scale parts or large structural components, a circular thread rolling machine can adapt to your needs.

Ease of Operation and Maintenance

Modern circular thread rolling machines are designed with user-friendliness in mind. Many models come equipped with advanced controls and automation features, reducing the learning curve for operators. Additionally, these machines typically require less maintenance compared to traditional machining equipment, allowing businesses to maximize uptime and productivity.

Conclusion

The decision to purchase a circular thread rolling machine can significantly enhance your manufacturing capabilities. With benefits such as precision, cost-effectiveness, versatility, and ease of operation, this investment can lead to improved product quality and production efficiency. As the demand for high-quality threaded components continues to grow, now is the ideal time to consider integrating a circular thread rolling machine into your operations. By doing so, your business can stay competitive and responsive to the evolving market demands.