-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Ion . 25, 2025 21:28

Back to list

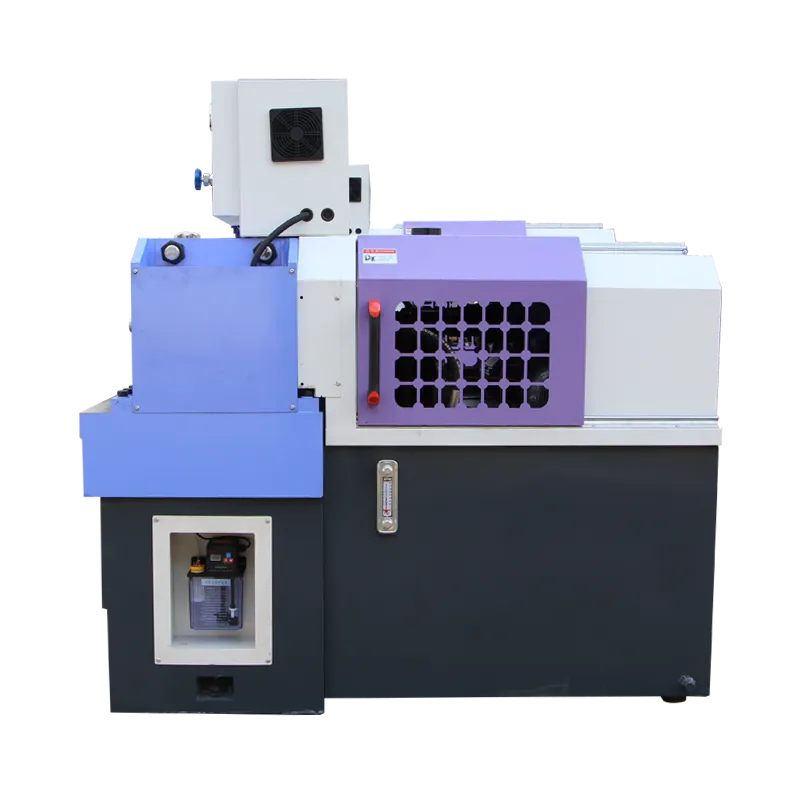

wholesale types of thread rolling machine

In the world of advanced manufacturing, thread rolling machines play a critical role in the efficient production of high-quality threaded components. These machines are indispensable for industries ranging from automotive to aerospace, ensuring precision thread formation and structural integrity. When considering purchasing wholesale types of thread rolling machines, understanding the different types and their applications will benefit manufacturers seeking to enhance their production capabilities.

The third category, planetary die thread rolling machines, employs a unique mechanism where multiple dies rotate around the workpiece. This method is praised for its efficiency in handling long, slender parts that are challenging to process with other types of machines. Planetary die machines offer seamless operation with reduced risk of workpiece deflection, making them the preferred choice for creating threads on long bars or intricate parts. Professionals within the manufacturing sector recognize the planetary system’s superiority in delivering both precision and speed, thus boosting overall production efficacy. When considering a wholesale purchase, it is essential to align the choice of machine with the specific operational requirements and goals of your manufacturing operations. Engaging with reputable vendors with a proven track record in the industry enhances trustworthiness and assurance in quality. Experts suggest evaluating the technical expertise of these providers, as well as their after-sales service capabilities, to ensure continued support and maintenance, factors central to maximizing the longevity and reliability of the machines. Authoritative resources and testimonials from industry experts can provide valuable insights into the practical applications and benefits of each machine type. Engaging with user forums and attending trade shows can also enhance understanding and competence concerning the latest advances in thread rolling technology. The decision to invest in thread rolling machines not only signifies a commitment to efficient production processes but also reflects a dedication to maintaining the highest standards of quality and reliability. Through informed choices underpinned by expert knowledge and authentic experiences, manufacturers can significantly enhance their capacities, aligning with the global demand for precision-engineered components. This strategic investment serves as a cornerstone for sustainable growth and competitive advantage in the dynamic manufacturing landscape.

The third category, planetary die thread rolling machines, employs a unique mechanism where multiple dies rotate around the workpiece. This method is praised for its efficiency in handling long, slender parts that are challenging to process with other types of machines. Planetary die machines offer seamless operation with reduced risk of workpiece deflection, making them the preferred choice for creating threads on long bars or intricate parts. Professionals within the manufacturing sector recognize the planetary system’s superiority in delivering both precision and speed, thus boosting overall production efficacy. When considering a wholesale purchase, it is essential to align the choice of machine with the specific operational requirements and goals of your manufacturing operations. Engaging with reputable vendors with a proven track record in the industry enhances trustworthiness and assurance in quality. Experts suggest evaluating the technical expertise of these providers, as well as their after-sales service capabilities, to ensure continued support and maintenance, factors central to maximizing the longevity and reliability of the machines. Authoritative resources and testimonials from industry experts can provide valuable insights into the practical applications and benefits of each machine type. Engaging with user forums and attending trade shows can also enhance understanding and competence concerning the latest advances in thread rolling technology. The decision to invest in thread rolling machines not only signifies a commitment to efficient production processes but also reflects a dedication to maintaining the highest standards of quality and reliability. Through informed choices underpinned by expert knowledge and authentic experiences, manufacturers can significantly enhance their capacities, aligning with the global demand for precision-engineered components. This strategic investment serves as a cornerstone for sustainable growth and competitive advantage in the dynamic manufacturing landscape.

Share:

Latest news

Vertical Thread Rolling Machine for Modern Manufacturing

NewsAug.06,2025

Thread Rolling Machine Price List for Every Budget

NewsAug.06,2025

Right Thread Rolling Machine for Sale

NewsAug.06,2025

Latest Types of Thread Rolling Machine

NewsAug.06,2025

Latest Pipe Thread Rolling Machine

NewsAug.06,2025

From Cutting to Forming: The Revolution of High-Speed Thread Rolling Machines

NewsAug.06,2025