-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Different Types of Thread Rolling Machines and Their Applications

Types of Thread Rolling Machines An Overview

Thread rolling machines are specialized equipment used in manufacturing processes to create external threads on cylindrical components. These machines utilize a cold forming process that allows for the efficient production of high-strength threads without removing material. There are several types of thread rolling machines, each designed for specific applications and producing different thread profiles. In this article, we will explore the primary types of thread rolling machines and their unique features.

1. Flat Die Thread Rolling Machines

Flat die thread rolling machines are among the simplest and most commonly used types in the industry. They employ two flat dies that move toward each other to compress the material of the workpiece. The workpiece is held between the dies and is rotated, which causes the dies to deform the material and create threads. This process is particularly effective for rolling a variety of thread forms, including UN, metric, and ACME threads. Flat die machines are ideal for high-volume production due to their efficiency and speed. They are commonly utilized in industries such as automotive, aerospace, and construction, where threaded components are crucial.

2. Circular Die Thread Rolling Machines

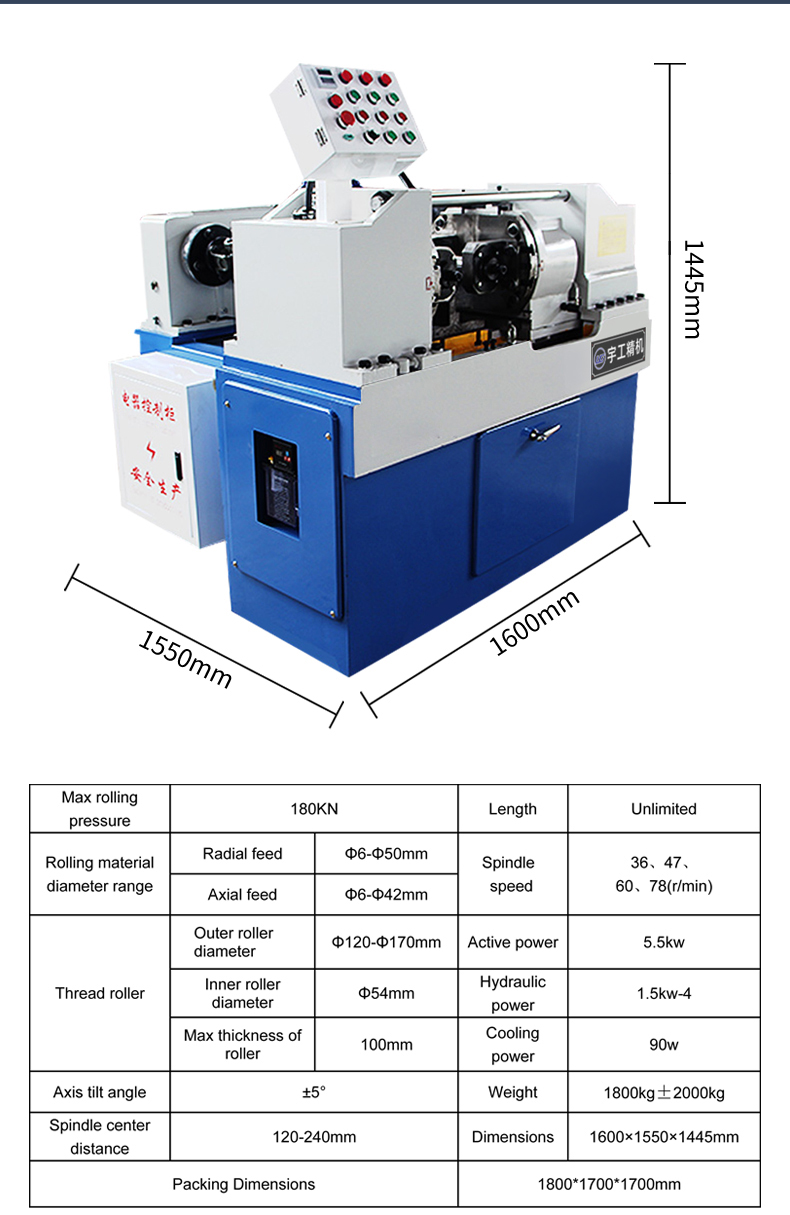

Circular die machines feature two cylindrical dies, which rotate synchronously to form threads on the workpiece as it is fed through the machine. This type of thread rolling is especially suitable for producing long and continuous threads due to the uniform force distribution from the circular dies. Circular die machines are preferred for applications requiring high precision and consistency, such as making screws, bolts, and other fasteners where dimensional accuracy is critical.

3. Multi-Station Thread Rolling Machines

types of thread rolling machine product

Multi-station thread rolling machines are designed to increase productivity and efficiency by allowing multiple operations to be performed simultaneously. These machines can accommodate various tooling setups, making them versatile for different thread sizes and profiles. Operators can load multiple workpieces at once, leading to higher output rates, making them ideal for large-scale manufacturing environments. Industries that require mass production of fasteners, such as electronics and appliances, frequently utilize multi-station thread rolling machines.

4. Vertical Thread Rolling Machines

Vertical thread rolling machines are engineered with the dies positioned vertically, providing certain advantages over their horizontal counterparts. This configuration allows for a better gravity effect on the workpiece, ensuring consistent engagement between the dies and the material. Vertical machines are also easier to set up and switch between different operations. They are particularly useful for producing specialized threads and can handle a range of materials, making them a valuable asset in various manufacturing domains.

5. Hydraulic Thread Rolling Machines

Hydraulic thread rolling machines use hydraulic systems to exert pressure on the threads being formed, allowing for better control over the rolling process. These machines are particularly effective for materials that are more challenging to work with, as hydraulic pressure can be adjusted to accommodate different material properties. This flexibility makes hydraulic machines well-suited for the production of intricate or specialized threads, often found in medical devices, aerospace components, and specialized machinery.

Conclusion

Choosing the right thread rolling machine for a specific application depends on various factors, including the type of thread to be produced, the material being used, and the desired production volume. Each type of machine offers distinct advantages and is optimized for different manufacturing needs. As technology continues to evolve, thread rolling machines are expected to integrate more advanced features, improving precision, efficiency, and automation in the manufacturing process. Understanding these different types of thread rolling machines aims to assist manufacturing businesses in selecting the most appropriate equipment, ensuring high-quality threaded components while maintaining production efficiency.