-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

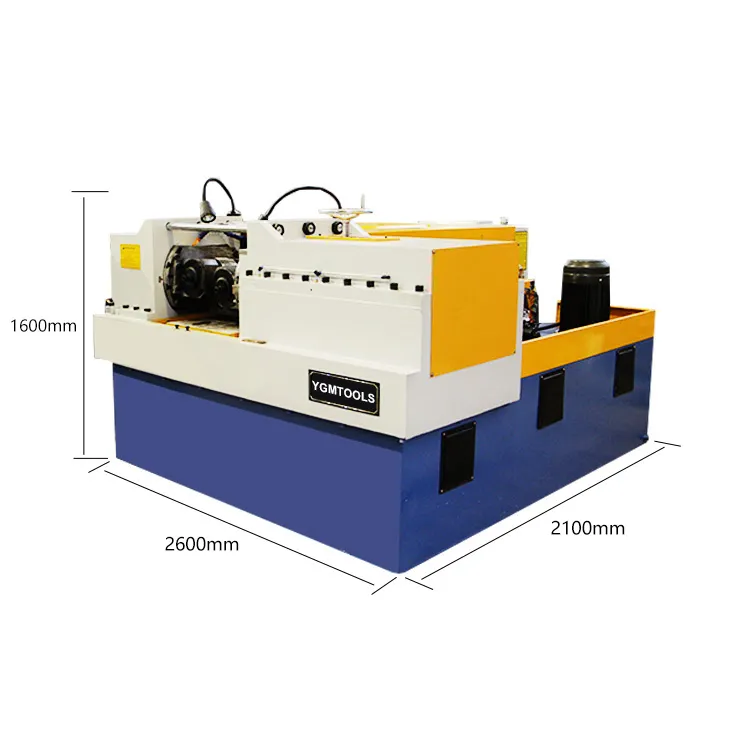

oem reed thread rolling machines

OEM Reed Thread Rolling Machines Revolutionizing the Manufacturing Process

In today’s fast-paced industrial landscape, the demand for precision-engineered components continues to grow. One of the key technologies that plays a pivotal role in meeting this demand is the thread rolling process. Among the various manufacturers in this field, OEM reed thread rolling machines stand out for their efficiency, precision, and reliability.

Thread rolling is a cold-forming process that creates threads on cylindrical parts through the application of high pressure. Compared to traditional machining methods, thread rolling offers significant advantages, including improved material strength, reduced waste, and faster production speeds. The OEM reed thread rolling machines leverage these benefits, making them an ideal choice for manufacturers across various sectors, including automotive, aerospace, and construction.

OEM Reed Thread Rolling Machines Revolutionizing the Manufacturing Process

In addition to precision, the durability and versatility of OEM reed thread rolling machines contribute significantly to their appeal. Designed to handle a wide array of materials, including steel, aluminum, and alloys, these machines can accommodate different thread sizes and types, making them suitable for diverse manufacturing needs. This adaptability not only enhances production flexibility but also reduces the need for multiple machines, thereby optimizing floor space and operational costs.

oem reed thread rolling machines

The importance of energy efficiency in modern manufacturing cannot be overstated. OEM reed thread rolling machines are engineered with energy-efficient features that minimize power consumption without compromising performance. This not only lowers operational costs for manufacturers but also aligns with global sustainability goals by reducing the carbon footprint associated with production processes.

Furthermore, technological advancements in automation and control systems have enhanced the usability of these machines. Many OEM reed thread rolling machines now come equipped with user-friendly interfaces and programmable settings, allowing operators to quickly adjust parameters for different production runs. This ease of use not only improves productivity but also reduces the learning curve for new operators, ensuring consistent output quality.

Moreover, OEM reed thread rolling machines are backed by robust customer support and maintenance services. Manufacturers can rely on their suppliers for regular maintenance, troubleshooting, and training, ensuring that the machines remain in optimal working condition throughout their operational life. This level of support is critical for minimizing downtime and maximizing production efficiency.

In conclusion, OEM reed thread rolling machines represent a significant advancement in manufacturing technology. Their precision, versatility, and energy efficiency make them indispensable tools for producing high-quality threaded components across various industries. As the market continues to evolve, these machines will undoubtedly play a crucial role in meeting the increasing demand for durable and reliable products, solidifying their place as a cornerstone of modern manufacturing processes. For companies looking to improve their production capabilities, investing in OEM reed thread rolling machines is a strategic decision that promises substantial returns in efficiency and quality.