-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Types of Thread Rolling Machines for Export and Their Applications

Types of Thread Rolling Machines and Their Export Opportunities

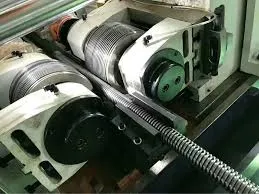

Thread rolling machines play a crucial role in the manufacturing of threads and fasteners across various industries. These machines utilize a unique process to form threads on different metal pieces, resulting in high precision and strength. As the demand for threaded products continues to rise globally, understanding the types of thread rolling machines and exploring their export opportunities is vital for manufacturers and exporters alike.

Types of Thread Rolling Machines

1. Flat Die Thread Rolling Machines One of the most common types, flat die machines, uses two flat dies to roll threads onto cylindrical workpieces. The process is efficient and produces threads that are uniform in depth and pitch. This type of machine is suitable for manufacturing screws, bolts, and other similar components.

2. Forming Thread Rolling Machines Forming machines often use two cylindrical dies to create threads. This continuous process minimizes waste and enhances the mechanical properties of the material due to the cold working effect. These machines are ideal for producing large quantities of threaded components quickly.

3. Inverted Thread Rolling Machines Inverted machines are designed for rolling threads on workpieces that are positioned upside down. This design allows for greater flexibility and the ability to work on larger components that may not fit in traditional machines. Inverted machines are gaining popularity for producing larger fasteners and automotive components.

4. Universal Thread Rolling Machines Universal thread rolling machines are versatile and can handle different types of workpieces and thread forms. These machines are equipped with interchangeable dies and settings, making them an efficient choice for manufacturers who require flexibility in production.

5. Roll Threading Machines Roll threading machines are specifically designed to produce rolled threads on long lengths of material. This type of machine is particularly effective for items such as rods and long bolts. Their ability to produce standard and custom thread types makes them a valuable asset in any manufacturing setup.

types of thread rolling machine exporter

Export Opportunities

The global demand for high-quality threaded components is expected to grow, driven by industries such as automotive, aerospace, and construction. As countries aim to boost their manufacturing sectors, the export of thread rolling machines presents lucrative opportunities for manufacturers.

1. Emerging Markets Countries in Southeast Asia, Africa, and South America are rapidly industrializing, resulting in increased demand for efficient manufacturing equipment, including thread rolling machines. Exporters can tap into these emerging markets by understanding local requirements and providing tailored solutions.

2. Technological Advancements With the advent of Industry 4.0, there is a growing demand for advanced machinery integrated with automation and smart technologies. Manufacturers that invest in modern thread rolling machines equipped with digital controls may find a competitive edge in foreign markets.

3. Trade Agreements Many countries are entering trade agreements that lower tariffs and encourage the import of machinery. Exporters should explore these agreements to optimize their supply chain and reduce costs, making their machines more attractive to international buyers.

4. Sustainability As sustainability becomes a priority globally, manufacturers that can demonstrate the energy efficiency and reduced waste of their thread rolling machines may find greater appeal in international markets. Machines designed for minimal energy consumption and reduced environmental impact can resonate well with eco-conscious buyers.

Conclusion

In conclusion, thread rolling machines are integral to the production of threaded fasteners across diverse industries. By understanding the various types of machines available and exploiting export opportunities in emerging markets, manufacturers can expand their reach and enhance their profitability. As the manufacturing landscape continues to evolve, staying ahead of industry trends and adapting to market demands will be essential for success in the global arena.