-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Competitive Prices for Thread Rolling Machines from Leading Manufacturers in the Industry

Understanding the Price Factors of Thread Rolling Machine Companies

Thread rolling machines are indispensable in various industrial applications, primarily for producing threads on cylindrical components. Companies looking to invest in thread rolling machines often have numerous questions, particularly concerning pricing. The price of these machines can fluctuate based on several factors, including the manufacturer, customization options, machine specifications, and technological advancements. This article aims to explore the essential aspects influencing the price of thread rolling machines and guide potential buyers in making informed decisions.

1. Manufacturer Reputation

The reputation of the manufacturer plays a crucial role in determining the price of thread rolling machines. Established companies with a long history of producing high-quality machinery tend to charge premium prices. This is often justified by the reliability, durability, and after-sales support that they offer. Buyers should consider companies with solid customer reviews and a track record of excellence, even if their initial pricing is higher. Conversely, newer companies may offer lower prices to attract customers but might lack the necessary support or reliability of established brands.

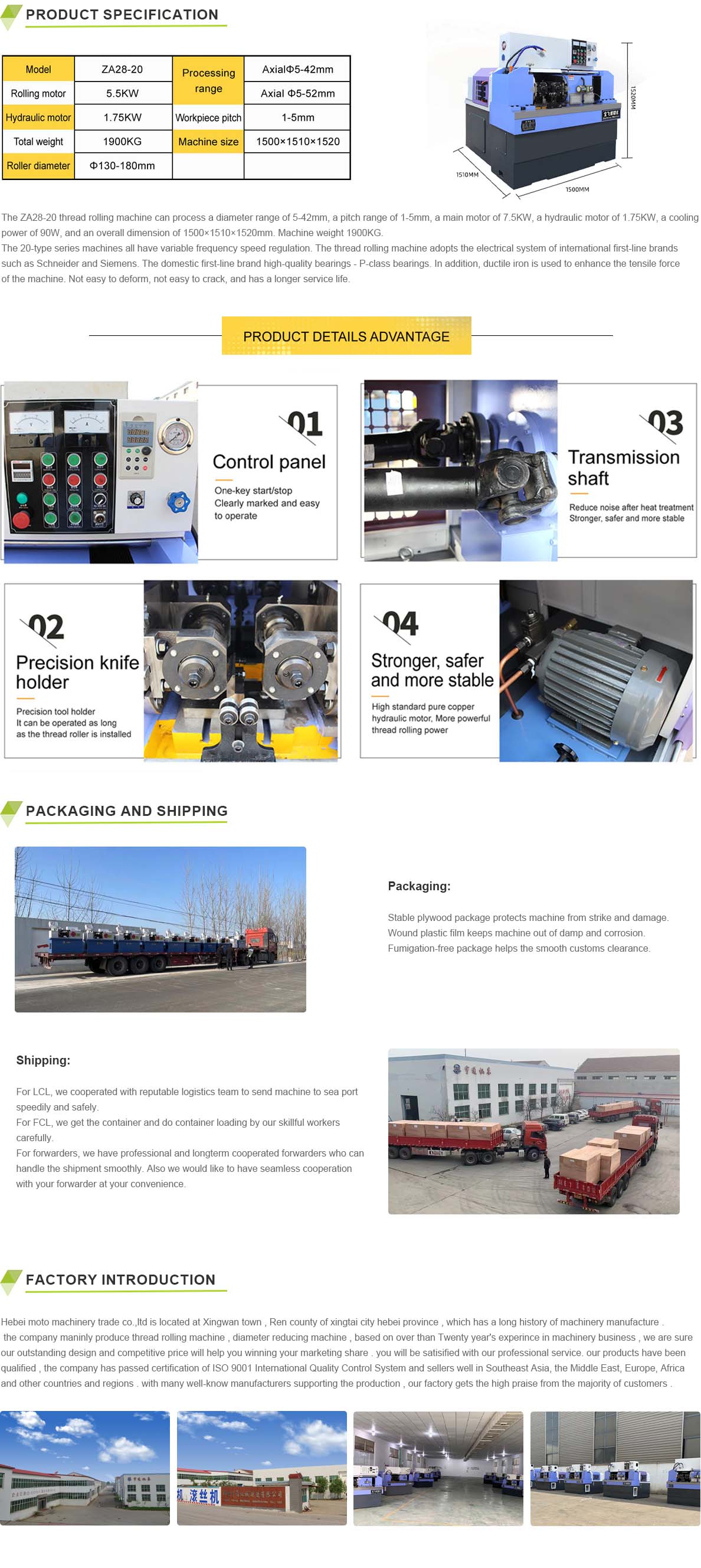

2. Specification and Features

The specifications of a thread rolling machine significantly impact its price. Features such as machine size, production capacity, and customization options directly correlate with cost. For instance, a machine that can handle larger diameters and produce intricate threading patterns will typically be priced higher than a basic model. Additionally, advanced features like programmable controls, automatic feed, and integrated safety systems enhance efficiency but also increase the overall cost. Companies must assess their specific needs carefully and understand that investing in higher-quality specifications can lead to better long-term outcomes.

3. Technology and Innovation

thread rolling machine price company

As with many industrial machines, technological advancements heavily influence the pricing of thread rolling machines. Modern machines equipped with the latest technology tend to command higher prices due to their increased efficiency, reduced waste, and superior output quality. For example, machines that utilize servo motors for precise control or those with enhanced software for monitoring and optimizing production processes can significantly improve operational efficiency. Companies should evaluate how these technological features can drive productivity and affect overall costs.

4. Customization and Production Volume

Customization also impacts pricing. Many companies require machines tailored to meet specific production needs, which can lead to increased costs. Custom features may include unique rolling dies, specialized feeds, or enhanced tooling setups. Moreover, the volume of production can influence the price as well. Larger orders often qualify for bulk pricing discounts, which can make a significant difference in the cost per unit.

5. Market Competition

Finally, the broader market landscape also plays a vital role in pricing. In regions with multiple manufacturers, competitive pricing can lead to more favorable rates. Companies can benefit from researching different suppliers and comparing prices to ensure they receive the best value for their investment. Obtaining quotes from multiple manufacturers and considering factors like warranty, service agreements, and delivery times can further aid in making a well-informed decision.

Conclusion

In summary, the price of thread rolling machines is influenced by a multitude of factors, including the manufacturer's reputation, machine specifications, technological advancements, customization options, and market competition. Potential buyers must conduct thorough research and evaluate their unique needs and budget constraints. By understanding these price determinants, companies can make informed decisions that maximize their investment and enhance their production capabilities. Ultimately, investing in the right thread rolling machine can contribute significantly to operational efficiency, product quality, and overall business success.