-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Circular Thread Rolling Machine Pricing and Specifications Guide

Understanding the Pricing Landscape of Circular Thread Rolling Machines

In the modern manufacturing environment, efficiency and precision are paramount, particularly in the production of threaded components. Circular thread rolling machines have emerged as vital tools in many industries, from automotive to aerospace, due to their ability to transform plain cylindrical blanks into intricately threaded parts with minimal waste and maximum strength. However, for businesses looking to invest in such machinery, understanding the pricing structure is crucial.

What is a Circular Thread Rolling Machine?

Circular thread rolling machines use a process that involves material deformation to create threads on the moving workpiece without cutting away any material. Instead, they rely on dies that impart the desired thread profile, thereby enhancing the mechanical properties of the component through work hardening. This method not only increases the integrity of the threaded parts but also allows for faster production speeds compared to traditional cutting methods.

Factors Influencing the Pricing

The cost of circular thread rolling machines can vary significantly based on several factors

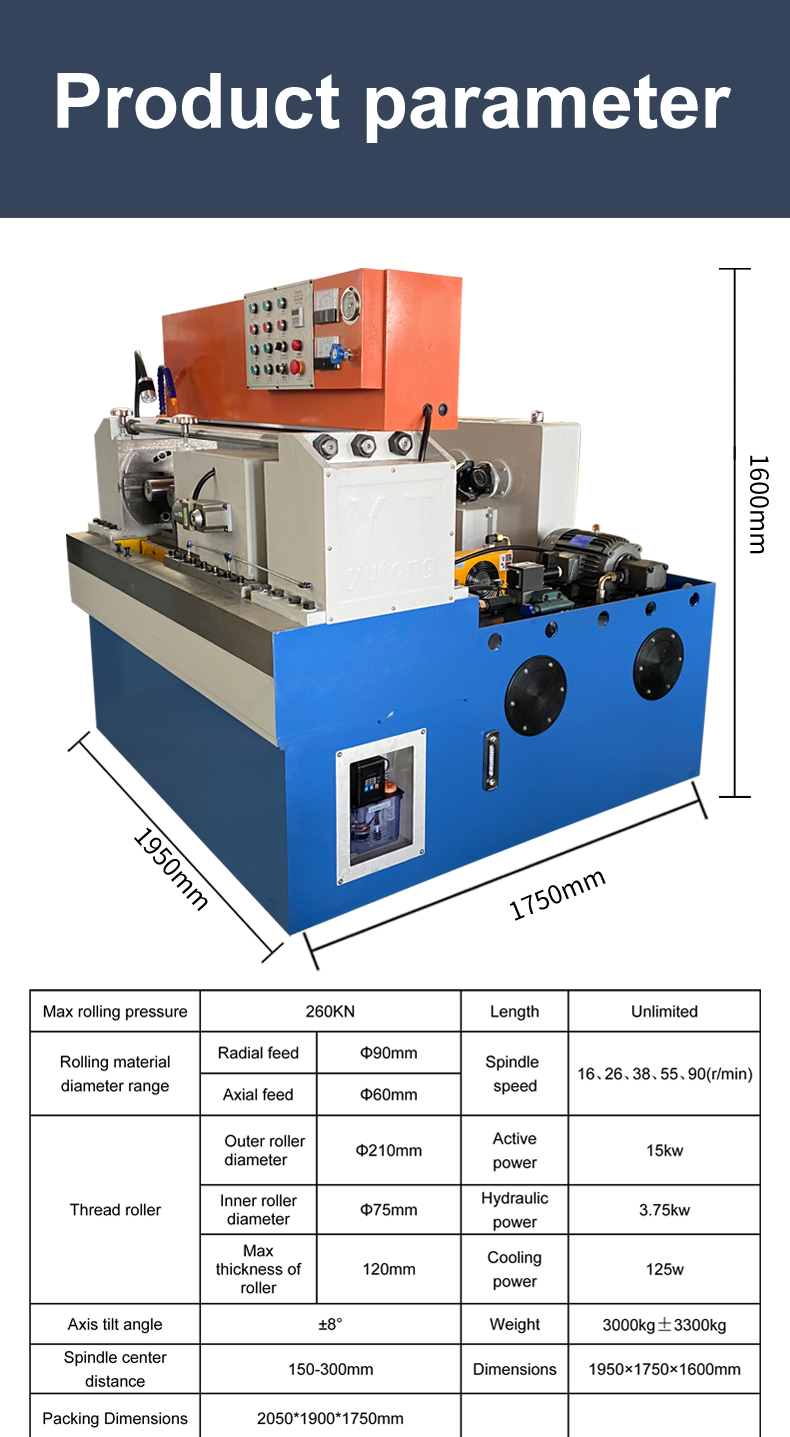

1. Machine Specifications The performance capabilities of the machine, including its size, speed, and the maximum diameter it can accommodate, greatly influence the price. High-capacity machines with advanced features typically come at a higher cost.

2. Brand Reputation Established manufacturers with a track record of reliability and performance often command higher prices. Investing in well-known brands can provide peace of mind, as these companies usually offer better after-sales support and service.

3. Technology Integration Modern machines may come equipped with advanced technological features, such as automation, CNC controls, and real-time monitoring systems. As technology continues to evolve, the incorporation of these features can lead to higher upfront costs but may offer long-term savings through increased efficiency.

4. Customization Manufacturers may require bespoke solutions tailored to their specific needs. Custom machines designed for unique applications can significantly elevate costs compared to standard offerings.

circular thread rolling machine pricelist

5. Market Demand and Supply Like any other product, the prices of circular thread rolling machines are also influenced by market dynamics. A sudden increase in demand—due to a manufacturing boom in a certain sector, for example—can drive prices up, while oversupply can cause costs to drop.

A Look at the Price Range

The price of circular thread rolling machines can range significantly. Generally, entry-level machines may start at around $20,000, while mid-range options can fall between $50,000 and $100,000. For high-end or customized machines, prices can soar beyond $200,000. Furthermore, maintenance and operational costs must also be factored into the total investment.

Leasing vs. Buying

For many businesses, particularly smaller manufacturers or startups, the decision to lease or buy a circular thread rolling machine can impact their financial planning. Leasing can minimize upfront costs, allowing companies to access high-quality machinery without a substantial capital outlay. However, over time, leasing costs may exceed the purchase price of a machine. Therefore, each business must evaluate its long-term goals and financial capabilities when making this decision.

The Future of Pricing in Circular Thread Rolling Machines

The growing trend of automation and Industry 4.0 is expected to influence the pricing of circular thread rolling machines. As manufacturers seek greater efficiency and precision, the integration of smart technologies will likely lead to an evolution in machine design and functionality. This shift could result in higher upfront costs, but the long-term benefits—including reduced labor costs and decreased cycle times—may justify the investment.

Conclusion

Investing in a circular thread rolling machine is a significant decision that can influence production efficiency and product quality. By understanding the various factors that contribute to pricing, businesses can make informed choices that align with their operational needs and budget constraints. As technology continues to advance, staying informed about trends in the market will help manufacturers adapt effectively and maintain a competitive edge in their respective industries.