-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ژوئن . 14, 2024 00:00

Back to list

Compact custom-made small thread rolling equipment

The Precision and Power of Custom Small Thread Rolling Machines

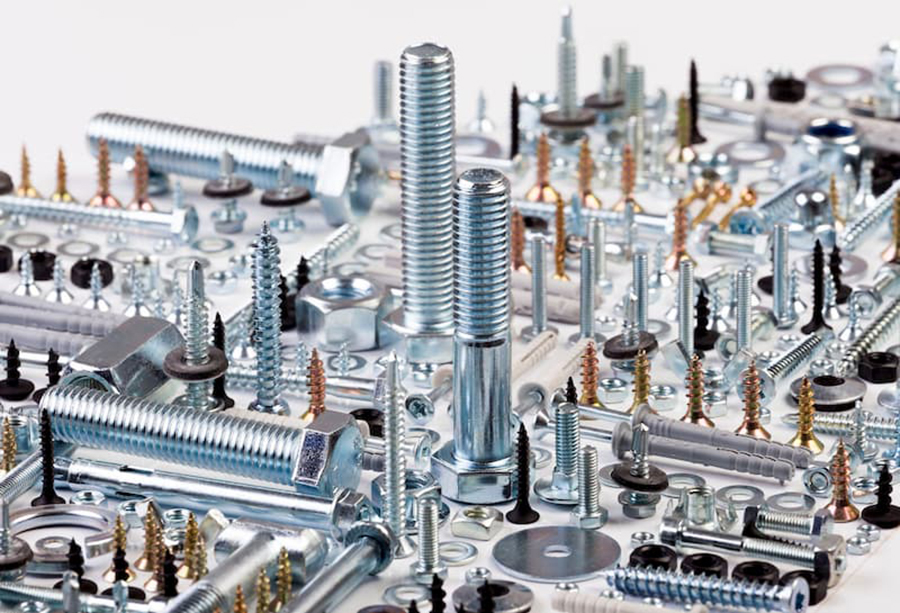

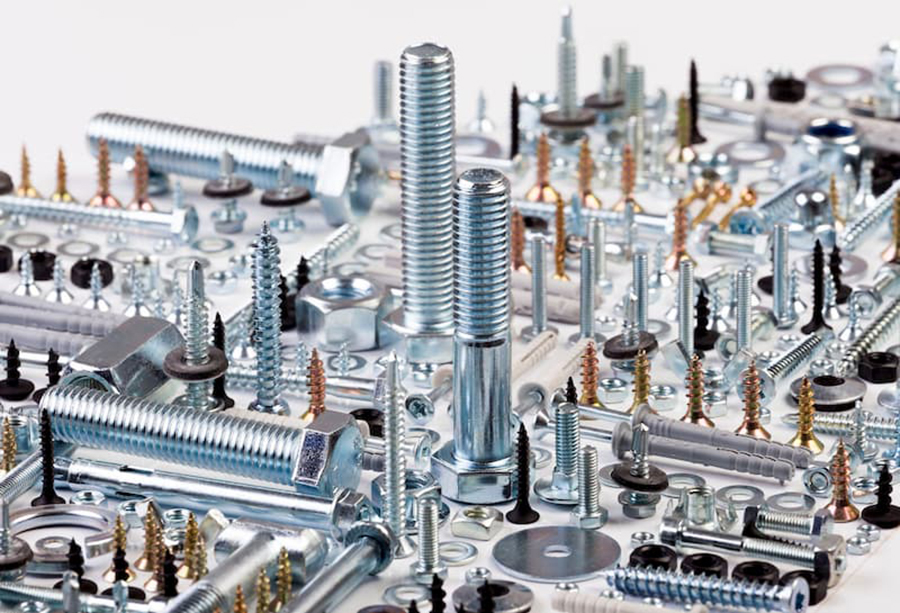

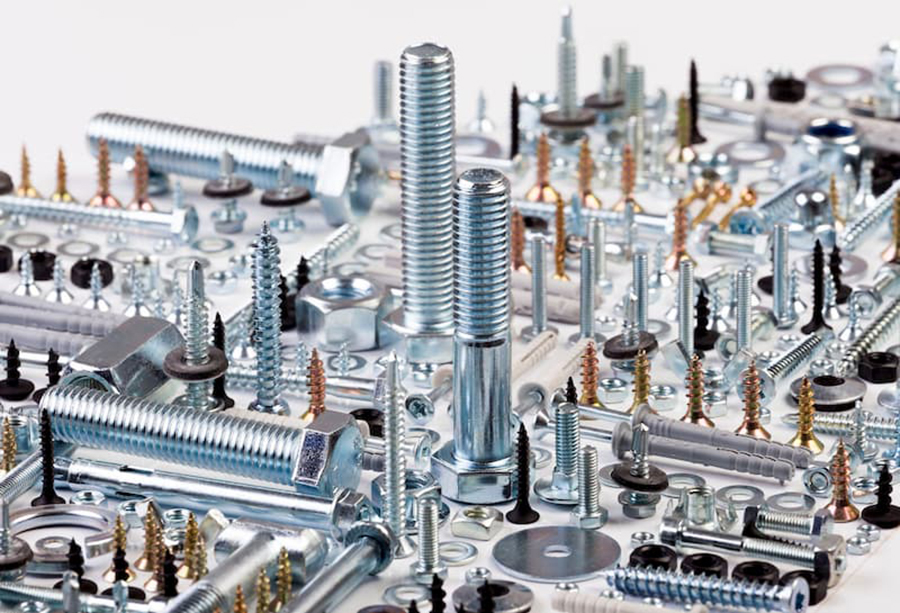

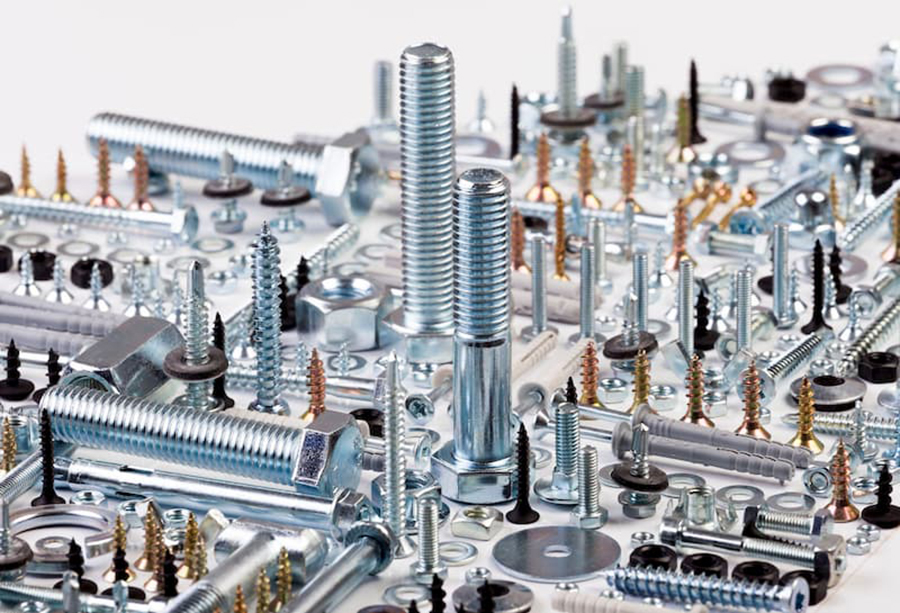

In the world of industrial manufacturing, precision engineering is paramount, and one tool that exemplifies this principle is the custom small thread rolling machine. This innovative piece of equipment is designed to deliver high-quality threads with exceptional accuracy, efficiency, and durability.

Thread rolling is a cold-forming process that involves shaping a thread on a material's surface by applying pressure with hardened dies. Unlike cutting methods, which remove material, thread rolling deforms the material, resulting in stronger threads with superior fatigue resistance. Custom small thread rolling machines are tailored to handle minute details and intricate designs, making them indispensable in various industries, including aerospace, automotive, and medical device manufacturing.

These specialized machines are built with custom specifications to cater to specific requirements, whether it's producing micro-sized threads for delicate instruments or complex geometries for high-stress applications. They offer an extensive range of capabilities, from producing standard threads to creating custom thread profiles that meet unique design specifications.

The compact size of these machines allows for easy integration into existing production lines, taking up minimal floor space while delivering maximum output. They often feature advanced control systems, enabling precise control over feed rates, pressure, and rotation speeds, ensuring consistent thread quality throughout the production process.

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels custom small thread rolling machine. Their robust construction and durable components ensure they can withstand the demands of high-volume production without compromising performance. Moreover, they are designed for longevity, reducing the need for frequent maintenance and replacement, thereby minimizing downtime and increasing productivity.

Furthermore, the custom small thread rolling process generates minimal waste, making it an environmentally friendly option compared to traditional threading techniques. The absence of burrs and the superior surface finish provided by these machines also contribute to the overall quality of the final product.

In conclusion, custom small thread rolling machines represent a significant advancement in manufacturing technology. They combine precision engineering, versatility, and efficiency to create threads that not only meet but exceed industry standards. As technology continues to evolve, so will these machines, further enhancing their capabilities and expanding their potential applications. Whether for mass production or niche manufacturing, the custom small thread rolling machine remains a vital tool in modern manufacturing, embodying the fusion of innovation and practicality.

custom small thread rolling machine. Their robust construction and durable components ensure they can withstand the demands of high-volume production without compromising performance. Moreover, they are designed for longevity, reducing the need for frequent maintenance and replacement, thereby minimizing downtime and increasing productivity.

Furthermore, the custom small thread rolling process generates minimal waste, making it an environmentally friendly option compared to traditional threading techniques. The absence of burrs and the superior surface finish provided by these machines also contribute to the overall quality of the final product.

In conclusion, custom small thread rolling machines represent a significant advancement in manufacturing technology. They combine precision engineering, versatility, and efficiency to create threads that not only meet but exceed industry standards. As technology continues to evolve, so will these machines, further enhancing their capabilities and expanding their potential applications. Whether for mass production or niche manufacturing, the custom small thread rolling machine remains a vital tool in modern manufacturing, embodying the fusion of innovation and practicality.

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels

One key advantage of custom small thread rolling machines is their ability to handle a wide range of materials, from soft alloys to hard steels custom small thread rolling machine. Their robust construction and durable components ensure they can withstand the demands of high-volume production without compromising performance. Moreover, they are designed for longevity, reducing the need for frequent maintenance and replacement, thereby minimizing downtime and increasing productivity.

Furthermore, the custom small thread rolling process generates minimal waste, making it an environmentally friendly option compared to traditional threading techniques. The absence of burrs and the superior surface finish provided by these machines also contribute to the overall quality of the final product.

In conclusion, custom small thread rolling machines represent a significant advancement in manufacturing technology. They combine precision engineering, versatility, and efficiency to create threads that not only meet but exceed industry standards. As technology continues to evolve, so will these machines, further enhancing their capabilities and expanding their potential applications. Whether for mass production or niche manufacturing, the custom small thread rolling machine remains a vital tool in modern manufacturing, embodying the fusion of innovation and practicality.

custom small thread rolling machine. Their robust construction and durable components ensure they can withstand the demands of high-volume production without compromising performance. Moreover, they are designed for longevity, reducing the need for frequent maintenance and replacement, thereby minimizing downtime and increasing productivity.

Furthermore, the custom small thread rolling process generates minimal waste, making it an environmentally friendly option compared to traditional threading techniques. The absence of burrs and the superior surface finish provided by these machines also contribute to the overall quality of the final product.

In conclusion, custom small thread rolling machines represent a significant advancement in manufacturing technology. They combine precision engineering, versatility, and efficiency to create threads that not only meet but exceed industry standards. As technology continues to evolve, so will these machines, further enhancing their capabilities and expanding their potential applications. Whether for mass production or niche manufacturing, the custom small thread rolling machine remains a vital tool in modern manufacturing, embodying the fusion of innovation and practicality. Share:

Latest news

Thread Rolling Tool Selection Guide

NewsJul.29,2025

Thread Rolling Machine Working Principle and Applications

NewsJul.29,2025

Rebar Thread Rolling Machine for Construction Sites

NewsJul.29,2025

Precision Control in Bolt Thread Rolling Machines

NewsJul.29,2025

Nail Thread Rolling Machine Safety Features

NewsJul.29,2025

Flat Thread Rolling Machine Thread Profile

NewsJul.29,2025