-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine working products

Thread Rolling Machine Revolutionizing Manufacturing Processes

In today’s fast-paced industrial landscape, the demand for precision-engineered components has never been higher. As manufacturers strive to meet the needs of various sectors, from automotive and aerospace to electronics and construction, the technologies they adopt become crucial in determining their success. One technology that has gained immense popularity is the thread rolling machine. This innovative piece of equipment plays a pivotal role in producing high-quality threaded products efficiently and cost-effectively.

Understanding Thread Rolling

Thread rolling is a cold forming process that creates threads on a workpiece by deforming the material. This process significantly differs from traditional machining methods like cutting, as it enhances the physical properties of the material while producing fewer waste products. The thread rolling method can be applied to various materials, including metals like steel, aluminum, and plastic composites, making it extremely versatile.

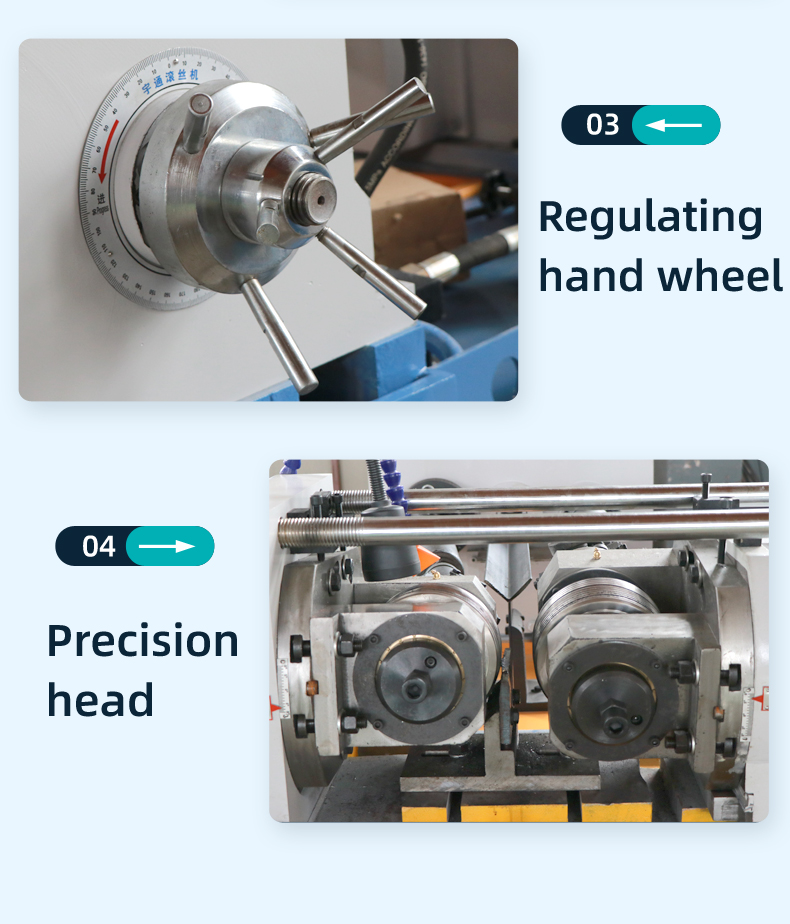

The basic principle behind thread rolling involves two or more hardened steel dies that press against the workpiece. As the workpiece is fed between the dies, the material is displaced, forming the desired thread profile. This process can be performed in several configurations, including flat, cylindrical, and planetary rolling, each suited for specific applications.

Advantages of Thread Rolling Machines

One of the most significant benefits of using thread rolling machines is their efficiency. Traditional machining processes can be time-consuming and expensive due to material waste and the need for detailed tooling. However, thread rolling machines can produce threads in a fraction of the time, allowing manufacturers to increase their output and reduce costs. Furthermore, since the process is cold forming, there is minimal heat generation, preserving the material's integrity and strength.

In addition to efficiency, the quality of the products produced by thread rolling machines is often superior to those made using conventional methods. The cold working process enhances the mechanical properties of the material, resulting in threads that exhibit improved tensile strength, fatigue resistance, and overall durability. These enhanced characteristics are essential for components subjected to high-stress environments, such as in automotive and aerospace applications.

Moreover, thread rolling allows for high precision, ensuring that the threads produced are uniform and consistent. This precision is crucial for applications requiring tight tolerances, where any misalignment can result in critical failures. By investing in thread rolling technology, manufacturers can guarantee the reliability and performance of their components.

thread rolling machine working products

Applications of Thread Rolling Machines

The applications of thread rolling machines are vast and varied. In the automotive industry, they are used to produce a wide range of components, including bolts, nuts, and gear rings. The aerospace sector benefits from thread rolling in the production of critical fasteners and structural components that must meet strict safety and performance standards.

In addition to the automotive and aerospace industries, thread rolling machines are instrumental in the manufacturing of electronic devices. Components such as connectors and screws are often produced using this technology, where precision and reliability are paramount. Even industries like construction and furniture manufacturing utilize thread rolling machines to create durable fittings and fasteners.

The Future of Thread Rolling Technology

As the demand for high-quality, precision-engineered products continues to grow, thread rolling technology is poised for further advancements. Manufacturers are investing in automation and robotics to streamline production processes, reduce labor costs, and improve efficiency. The integration of smart technologies and data analytics is also on the rise, allowing for enhanced monitoring of the production cycle and real-time quality control.

Additionally, with the increasing focus on sustainability, the thread rolling process's minimal waste generation and energy efficiency make it an attractive option for manufacturers looking to reduce their environmental impact.

Conclusion

In conclusion, thread rolling machines represent a significant advancement in manufacturing technology. Their ability to produce high-quality, precise threaded products efficiently and sustainably positions them as a crucial asset for modern manufacturers. As industries continue to evolve, the importance of such innovative solutions will only increase, ultimately shaping the future of production in various sectors. By adopting thread rolling technology, manufacturers are not merely keeping pace with industry demands; they are setting new standards for quality and efficiency in production.