-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

rebar thread rolling machine supplier

The Importance of Rebar Thread Rolling Machines in Construction

In the modern construction industry, efficiency and precision are paramount. One critical component that has significantly enhanced these aspects is the rebar thread rolling machine. These machines are essential for the production of threaded rebar, which is widely used in various construction applications. As infrastructure development accelerates globally, the demand for reliable rebar thread rolling machine suppliers has surged.

Rebar thread rolling machines are specialized equipment designed to create threads on reinforcing bars (rebar). The process of rolling threads onto rebar enhances its flexibility and strength, allowing for easy connections in reinforced concrete structures. Unlike traditional methods like cutting or welding, thread rolling ensures that the structural integrity of the rebar is maintained, providing a stronger bond within concrete.

One of the key advantages of using a rebar thread rolling machine is efficiency. These machines operate at high speeds, allowing manufacturers to produce large quantities of threaded rebar in a short period. This rapid production capability is crucial in meeting the demands of large-scale construction projects where time constraints are a significant concern. Moreover, the automation of the thread rolling process minimizes labor costs and reduces the potential for human error, further increasing productivity.

Precision is another critical factor in rebar thread production. Subpar threading can lead to weak joints that compromise the safety and durability of a structure. High-quality rebar thread rolling machines are engineered to offer consistent and precise thread profiles, ensuring that every piece of rebar meets the specified standards. This level of precision is not only vital for the structural integrity but also for meeting regulatory compliance in construction projects.

rebar thread rolling machine supplier

When seeking a rebar thread rolling machine supplier, it’s essential to consider several factors. The reputation of the supplier within the industry is paramount; established suppliers are likely to provide high-quality machines and reliable customer service. Additionally, evaluating the range of products and services offered by a supplier can be advantageous. Are they providing comprehensive support, including machine maintenance and troubleshooting? Such services can significantly enhance the longevity and functionality of the equipment.

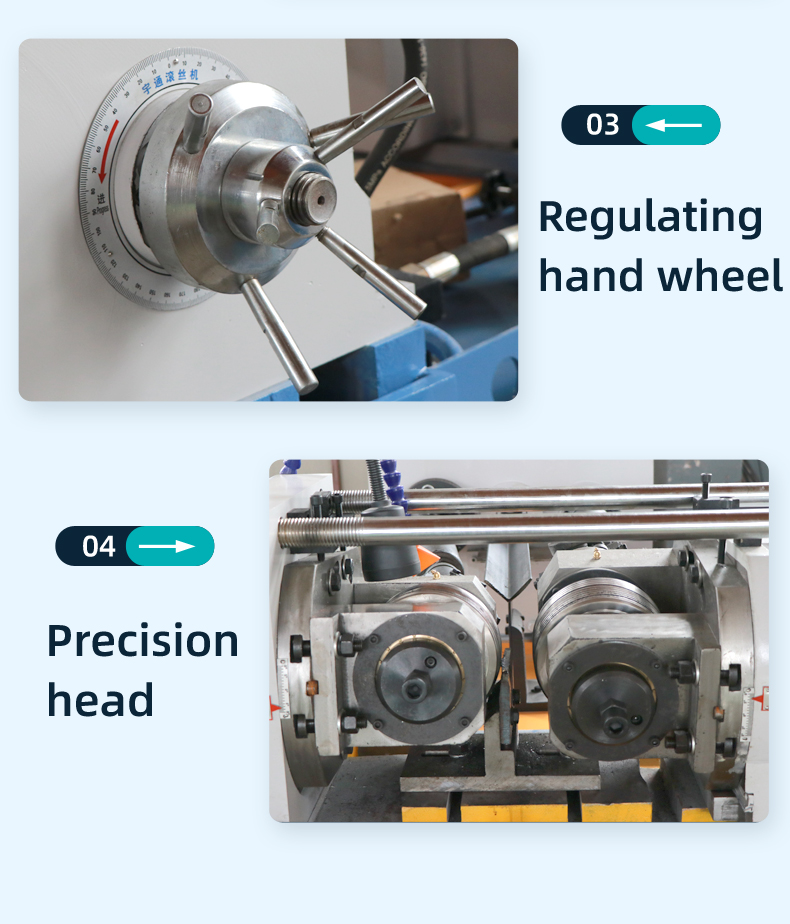

Another consideration is the technological advancement of the machines. Modern rebar thread rolling machines come equipped with advanced features such as digital controls, automatic feeding systems, and enhanced safety mechanisms. Suppliers who invest in technology not only improve the efficiency of operations but also offer machines that are easier to use and maintain.

Finally, factors such as pricing and warranty should also influence the decision when selecting a supplier. It’s crucial to balance cost with quality; cheaper machines may lead to higher long-term costs due to repairs and inefficiencies.

In conclusion, the role of rebar thread rolling machines in construction cannot be overstated. These machines not only enhance efficiency and precision in rebar production but also ensure the structural integrity of buildings and infrastructure. When choosing a supplier, it’s essential to weigh factors such as reputation, technology, and support services. Investing in high-quality rebar thread rolling machines is an investment in the future of safe and durable construction.