-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Xan . 09, 2025 13:45

Back to list

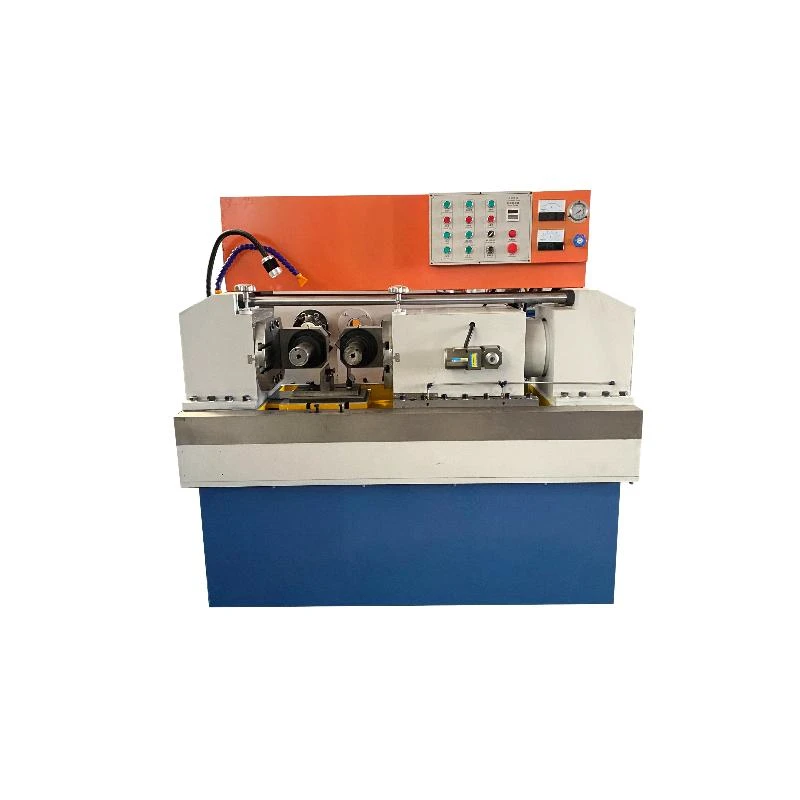

thread rolling machine for sale

When searching for the perfect thread rolling machine for sale, understanding the intricate details of these machines can significantly impact your purchasing decision. Thread rolling is a process that forms screw threads by pressing a hardened die against the surface of a cylindrical blank. This technique promises improved thread accuracy, increased strength, and a smoother finish compared to traditional cutting methods.

From an operational standpoint, thread rolling machines are inherently energy-efficient, thanks to their minimal material waste and rapid production times. Thread rolling employs a cold-forming process, which not only conserves energy compared to heat-intensive cutting methods but also enhances the material's grain structure, resulting in stronger threads. Investing in a high-quality thread rolling machine also means investing in durability and ease of maintenance. Machines with robust construction from reputable manufacturers typically feature longer lifespans and come with comprehensive maintenance support and parts availability. A well-maintained machine ensures long-term cost savings and reduced production downtime. When considering a purchase, evaluate the manufacturer’s support and training offerings. Are there detailed manuals, accessible technical support, and workshops available to maximize your machine's capabilities? A reliable manufacturer will provide thorough training to ensure your team is adept at operating and maintaining the machine, adding another layer of trustworthiness to your investment. In conclusion, the process of selecting a thread rolling machine involves a comprehensive evaluation of several critical factors. From understanding the machine’s operational mechanics to assessing its material compatibility, precision, energy efficiency, and manufacturer support, making an informed decision supports long-term operational efficiency and product quality. As you explore options for a thread rolling machine for sale, prioritizing these key aspects ensures a seamless integration into your production line, heralding enhanced productivity and superior end products.

From an operational standpoint, thread rolling machines are inherently energy-efficient, thanks to their minimal material waste and rapid production times. Thread rolling employs a cold-forming process, which not only conserves energy compared to heat-intensive cutting methods but also enhances the material's grain structure, resulting in stronger threads. Investing in a high-quality thread rolling machine also means investing in durability and ease of maintenance. Machines with robust construction from reputable manufacturers typically feature longer lifespans and come with comprehensive maintenance support and parts availability. A well-maintained machine ensures long-term cost savings and reduced production downtime. When considering a purchase, evaluate the manufacturer’s support and training offerings. Are there detailed manuals, accessible technical support, and workshops available to maximize your machine's capabilities? A reliable manufacturer will provide thorough training to ensure your team is adept at operating and maintaining the machine, adding another layer of trustworthiness to your investment. In conclusion, the process of selecting a thread rolling machine involves a comprehensive evaluation of several critical factors. From understanding the machine’s operational mechanics to assessing its material compatibility, precision, energy efficiency, and manufacturer support, making an informed decision supports long-term operational efficiency and product quality. As you explore options for a thread rolling machine for sale, prioritizing these key aspects ensures a seamless integration into your production line, heralding enhanced productivity and superior end products.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025