-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

જૂન . 15, 2024 21:33

Back to list

Thread rolling a versatile manufacturing technique.

Exploring the Diverse World of Thread Rolling Techniques

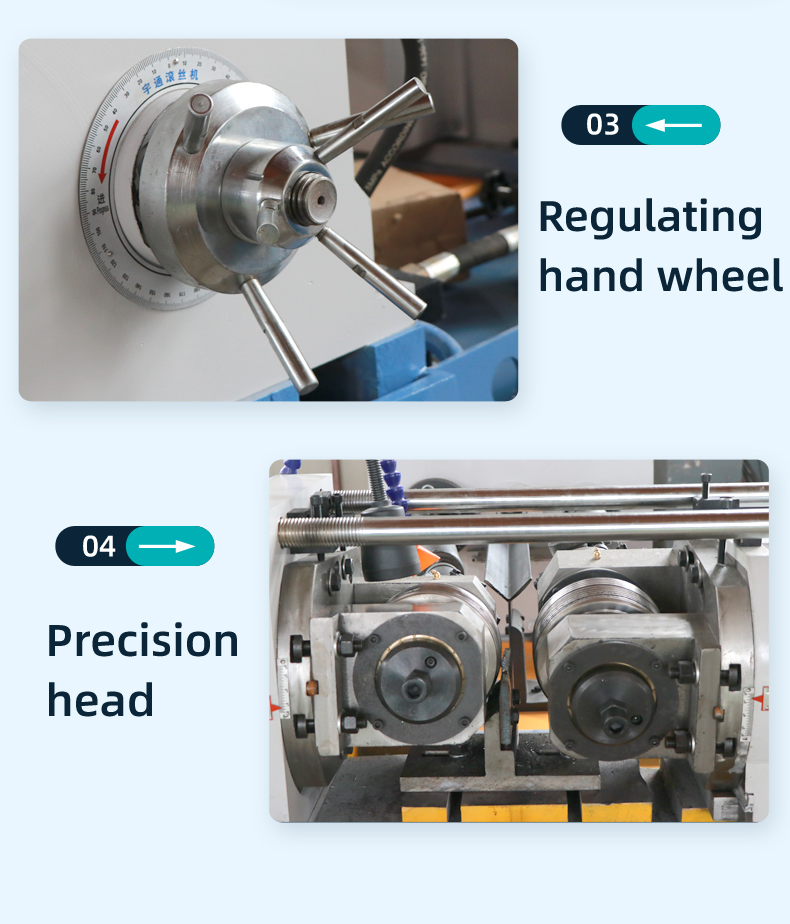

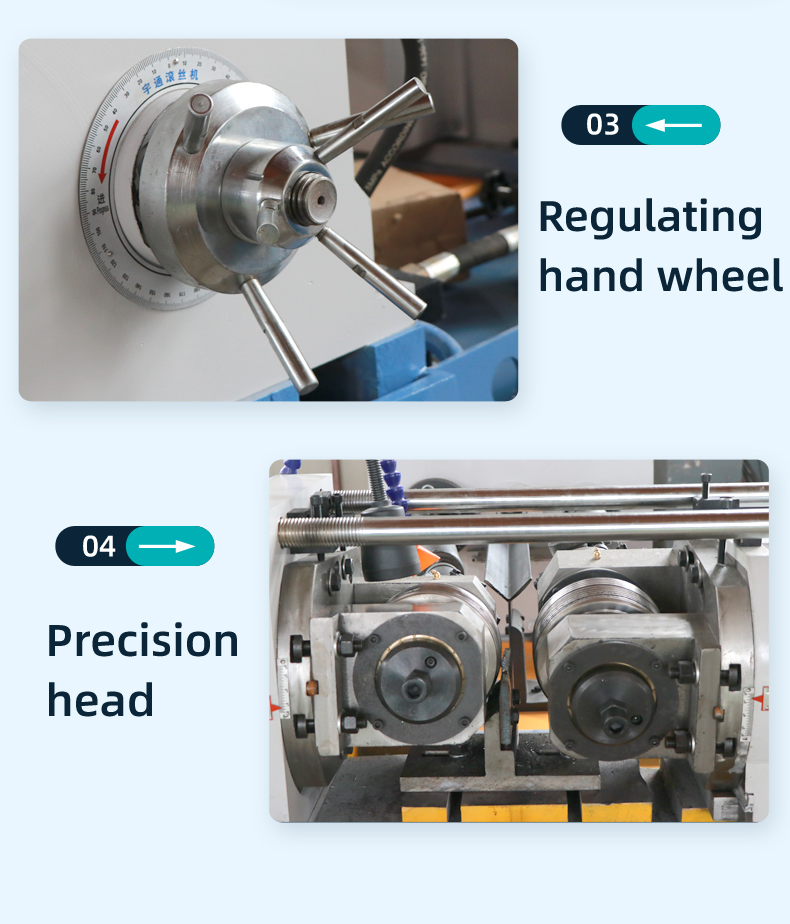

The art of thread rolling, a precision metal forming process, stands at the forefront of modern manufacturing. This technique, which involves compressing and deforming materials to create threads, offers significant advantages over traditional cutting methods. By understanding the two main types of thread rolling processes—axial and radial—we can appreciate the versatility and efficiency inherent in this advanced technology.

Axial thread rolling, also known as straight thread rolling, is typically utilized for producing internal threads. In this method, two hardened steel dies move parallel to the axis of the workpiece. They compress the material, plastically deforming it to form the thread profile. The process is repeated until the desired depth and precision of the thread are achieved. Axial thread rolling is favored for its ability to produce threads with high surface quality and excellent physical properties, such as increased fatigue strength due to work hardening.

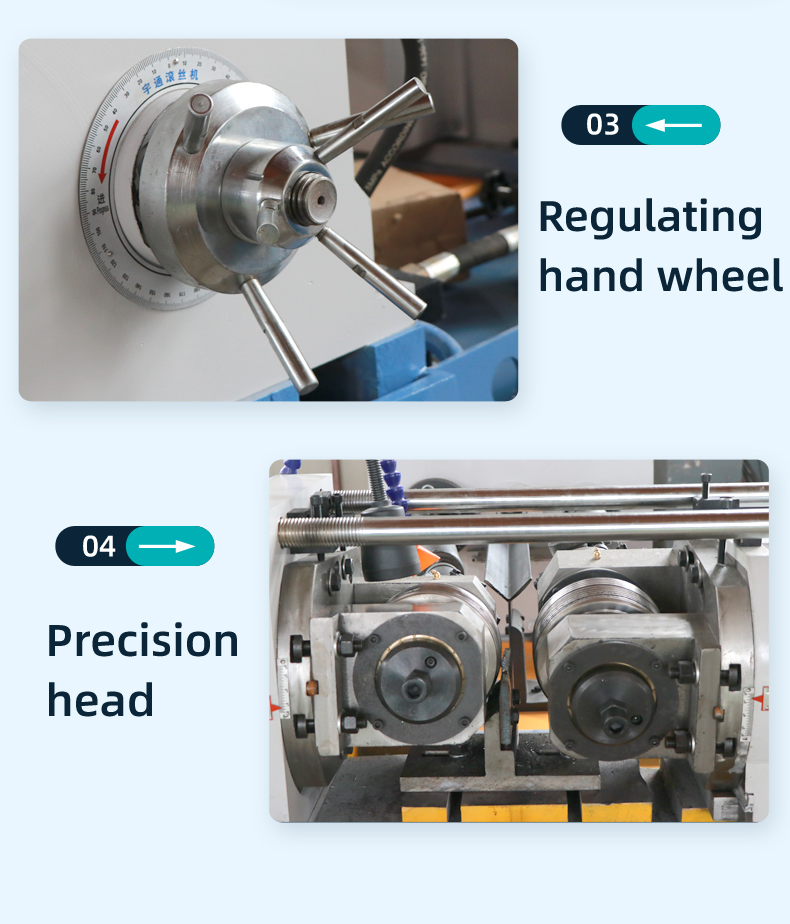

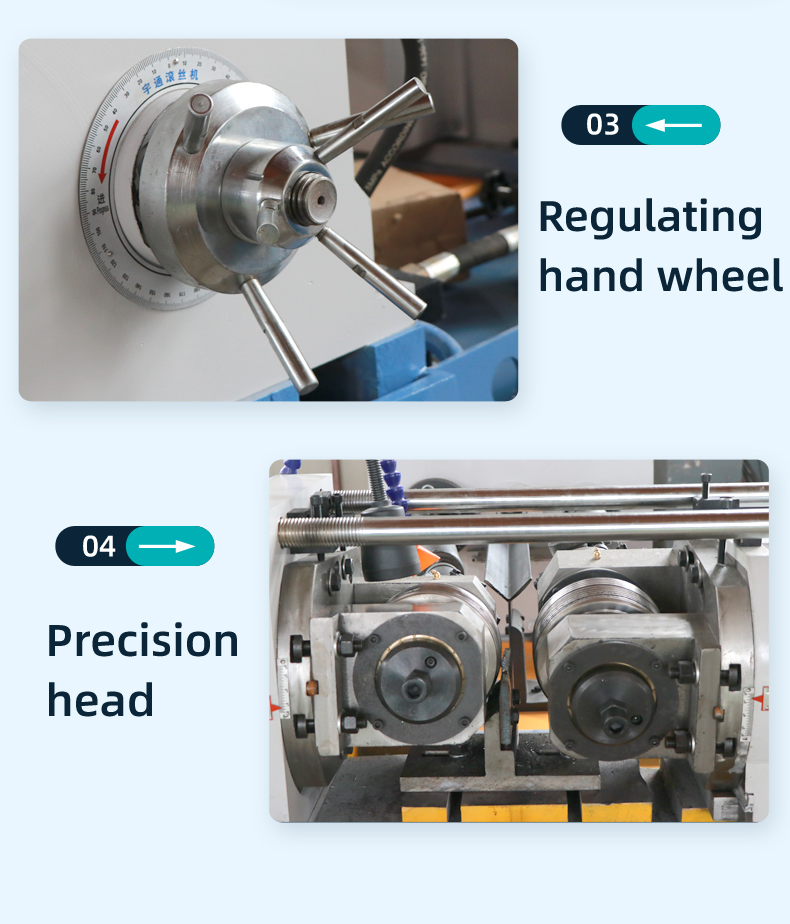

On the other hand, radial thread rolling, or planetary thread rolling, is employed for external threads. It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece

It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece odm types of thread rolling. As the dies rotate and press against the material, they create the thread form without any chip removal. This method is particularly effective for long pieces or large batch productions, offering high throughput rates and consistent results.

Both methods offer distinct benefits. Axial rolling is ideal for tight tolerances and complex geometries, while radial rolling excels in rapid production and uniformity across longer lengths. The selection between these techniques often depends on the application's specific requirements, such as thread size, part configuration, and material properties.

In conclusion, thread rolling presents an innovative solution to the age-old challenge of thread creation. Whether through axial or radial means, it delivers superior mechanical properties and enhanced production efficiency. As we continue to push the boundaries of manufacturing, the sophistication of thread rolling techniques promises to propel us toward even more intricate and reliable fastening solutions.

odm types of thread rolling. As the dies rotate and press against the material, they create the thread form without any chip removal. This method is particularly effective for long pieces or large batch productions, offering high throughput rates and consistent results.

Both methods offer distinct benefits. Axial rolling is ideal for tight tolerances and complex geometries, while radial rolling excels in rapid production and uniformity across longer lengths. The selection between these techniques often depends on the application's specific requirements, such as thread size, part configuration, and material properties.

In conclusion, thread rolling presents an innovative solution to the age-old challenge of thread creation. Whether through axial or radial means, it delivers superior mechanical properties and enhanced production efficiency. As we continue to push the boundaries of manufacturing, the sophistication of thread rolling techniques promises to propel us toward even more intricate and reliable fastening solutions.

It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece

It involves three or more dies that move in a planetary motion around the circumference of the workpiece It involves three or more dies that move in a planetary motion around the circumference of the workpiece odm types of thread rolling. As the dies rotate and press against the material, they create the thread form without any chip removal. This method is particularly effective for long pieces or large batch productions, offering high throughput rates and consistent results.

Both methods offer distinct benefits. Axial rolling is ideal for tight tolerances and complex geometries, while radial rolling excels in rapid production and uniformity across longer lengths. The selection between these techniques often depends on the application's specific requirements, such as thread size, part configuration, and material properties.

In conclusion, thread rolling presents an innovative solution to the age-old challenge of thread creation. Whether through axial or radial means, it delivers superior mechanical properties and enhanced production efficiency. As we continue to push the boundaries of manufacturing, the sophistication of thread rolling techniques promises to propel us toward even more intricate and reliable fastening solutions.

odm types of thread rolling. As the dies rotate and press against the material, they create the thread form without any chip removal. This method is particularly effective for long pieces or large batch productions, offering high throughput rates and consistent results.

Both methods offer distinct benefits. Axial rolling is ideal for tight tolerances and complex geometries, while radial rolling excels in rapid production and uniformity across longer lengths. The selection between these techniques often depends on the application's specific requirements, such as thread size, part configuration, and material properties.

In conclusion, thread rolling presents an innovative solution to the age-old challenge of thread creation. Whether through axial or radial means, it delivers superior mechanical properties and enhanced production efficiency. As we continue to push the boundaries of manufacturing, the sophistication of thread rolling techniques promises to propel us toward even more intricate and reliable fastening solutions. Share:

Latest news

Thread Rolling Machine: A Critical Tool for Industrial Metal Forming

NewsMay.06,2025

Thread Rolling Machine Suppliers

NewsMay.06,2025

Scaffolding Pipe Thread Rolling Machine

NewsMay.06,2025

Hydraulic Thread Rolling Machine Manufacturers

NewsMay.06,2025

High Speed Thread Rolling Machine

NewsMay.06,2025

Automatic Thread Rolling Machine

NewsMay.06,2025