-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

china thread rolling machine setup

The Setup of China Thread Rolling Machines A Comprehensive Guide

Thread rolling machines are essential tools in the manufacturing industry, particularly in the production of fasteners, bolts, and various threaded components. In China, these machines have gained significant traction due to their efficiency, precision, and ability to cater to various industrial needs. Setting up a thread rolling machine is a critical process that involves several steps to ensure optimal performance and output quality.

Understanding Thread Rolling Machines

Thread rolling is a cold-forming process that deforms the material to create threads. This method is preferred over cutting threads because it offers better surface finish, improved mechanical properties, and higher production speed. In China, manufacturers produce a wide range of thread rolling machines that vary in size, capacity, and technology, allowing businesses to choose an appropriate model for their requirements.

Preparing for Setup

Before setting up a thread rolling machine, it is vital to select an adequate location that facilitates easy access and maximizes workflow efficiency. The area should be free from clutter and have proper ventilation, as some machines might generate heat during operation. Additionally, ensure that the electrical supply meets the machine’s specifications to avoid malfunctions.

Step-by-Step Setup Process

1. Unpacking and Inspecting the Machine Upon receiving the machine, unpack it carefully and inspect for any damages during transit. Ensure that all components, including dies, are included.

china thread rolling machine setup

2. Assembly If the machine requires assembly, follow the manufacturer’s instructions meticulously. Use the appropriate tools and ensure all parts are securely fastened.

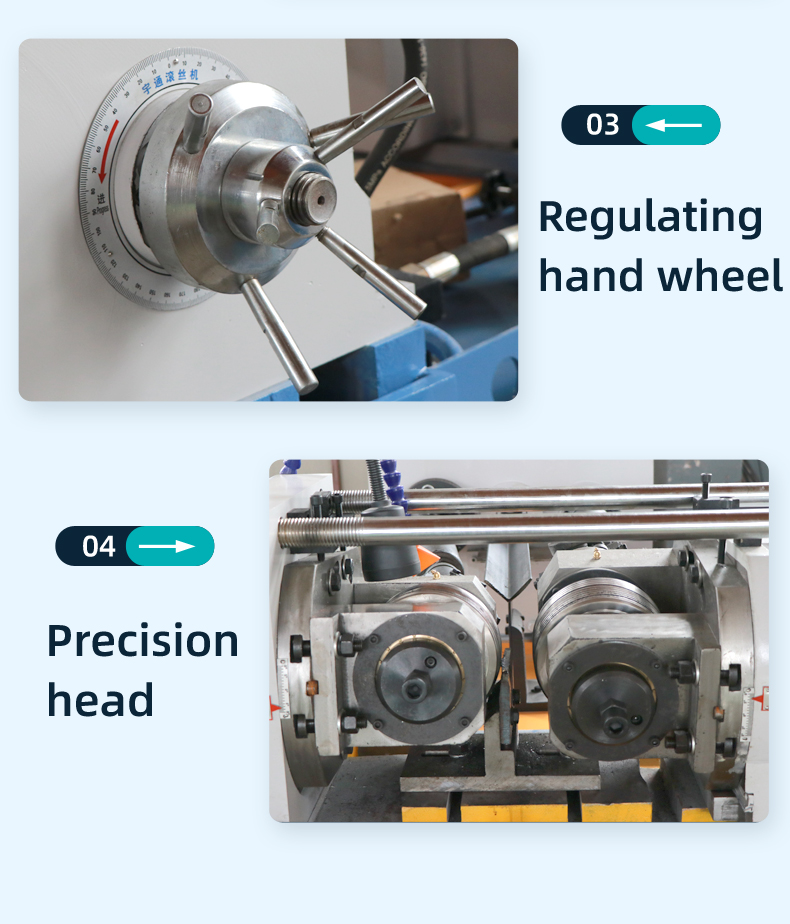

3. Installing the Dies The die is a critical component for thread rolling. Choose the correct die set based on the desired thread specifications. Install them securely according to the manufacturer’s guidelines, paying attention to the alignment to guarantee precision in thread formation.

4. Setting Up Power Supply Connect the machine to the power supply, ensuring that all electrical connections are insulated and properly secured. Check the voltage requirements and ensure they match with the supply.

5. Adjusting Operating Parameters Before starting the machine, adjust the rolling speed and feed rate based on the material type and thickness. Proper adjustments can lead to enhanced thread quality and reduced wear on the dies.

6. Testing the Machine Conduct a test run using a sample material. Observe the machine’s operation closely, making any necessary adjustments to the speed and feed rate if required. Inspect the threads produced for quality assurance.

Conclusion

Setting up a thread rolling machine in China requires careful preparation and attention to detail. By following the structured setup process, manufacturers can ensure that their machines operate efficiently, producing high-quality threaded components that meet industry standards. As the demand for precision-engineered parts continues to grow, mastering the setup of thread rolling machines is crucial for success in the manufacturing sector.