-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

Turanci

Turanci -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Thread Rolling Machine Working Principle and Applications

Thread Rolling Machine Basic Working Principle

- The thread rolling machineoperates through a cold-forming process that displaces material rather than cutting it

• Two or three hardened rolling dies apply extreme pressure to a rotating workpiece to form threads

• This thread rolling machineprocess creates threads with superior strength compared to cut threads

• The absence of material removal results in no waste chips and higher production efficiency

• Threads produced by thread rolling machine have improved fatigue resistance and surface finish

Roller Threading Machine Key Components and Functions

- Roller threading machinedies: Made from high-grade tool steel for durability and precision

• Spindle assembly: Rotates the workpiece at controlled speeds during thread formation

• Feed mechanism: Precisely controls die movement for accurate thread pitch

• Hydraulic/pneumatic system: Provides necessary forming pressure in the roller threading machine

• Frame construction: Uses ductile iron for enhanced stability and vibration resistance

Automatic Thread Rolling Machine Operational Advantages

- Automatic thread rolling machinesignificantly increases production output through continuous operation

• Programmable controls in automatic thread rolling machine ensure consistent thread quality

• Reduced labor requirements compared to manual threading methods

• Automatic thread rolling machine can integrate with robotic loading/unloading systems

• Advanced sensors in automatic thread rolling machine prevent defects and ensure process reliability

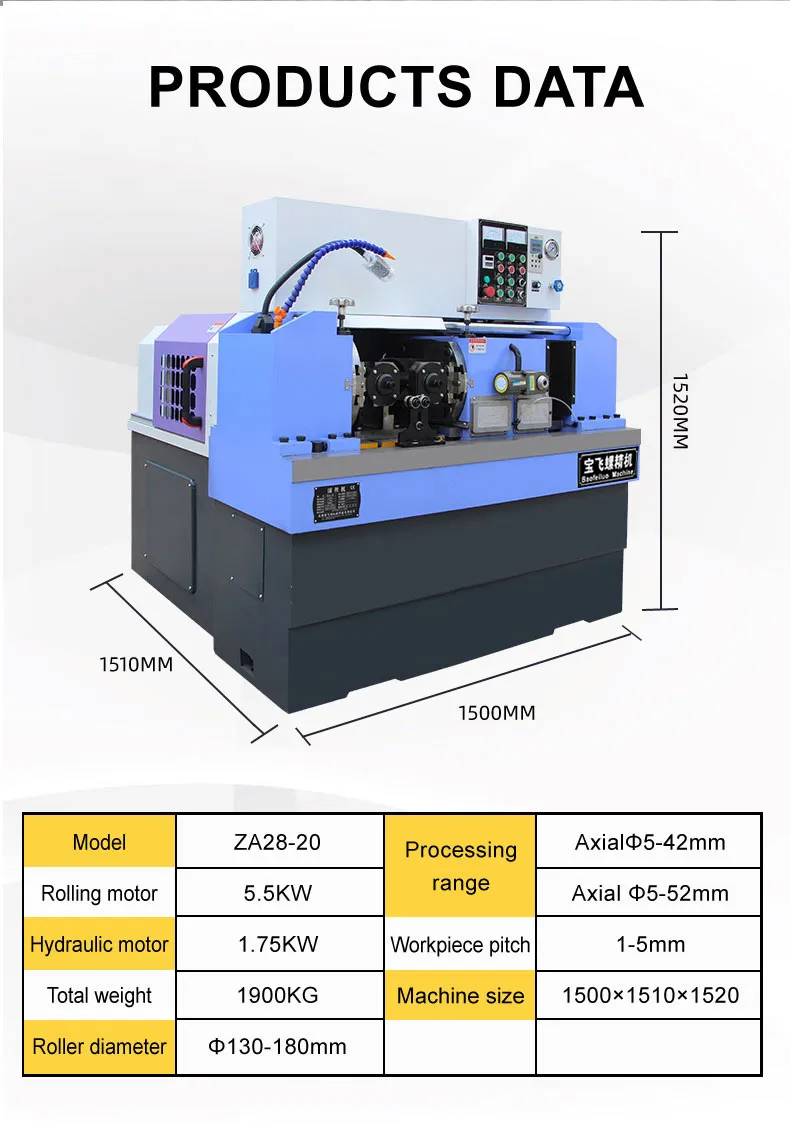

Thread Rolling Machine Technical Specifications

- 20-type series thread rolling machinefeatures variable frequency speed regulation

• Uses premium Schneider/Siemens electrical components for reliable operation

• Equipped with domestic P-class high-precision bearings

• Ductile iron construction enhances machine durability and stability

• Thread rolling machinecapacity ranges from M3 to M24 thread sizes

Roller Threading Machine Packaging Details

- Heavy-duty plywood cases protect roller threading machineduring transportation

• Plastic film wrapping prevents moisture damage to machine components

• Fumigation-free packaging meets international shipping requirements

• Customized packaging solutions available for special roller threading machinemodels

• Clear labeling ensures proper handling of roller threading machine shipments

Automatic Thread Rolling Machine Shipping Options

- LCL shipments arranged through reliable logistics partners for automatic thread rolling machine

• FCL container loading performed by experienced technicians

• Professional forwarders handle customs clearance for automatic thread rolling machineexports

• Door-to-door delivery options available for automatic thread rolling machinepurchases

• Real-time tracking provided for all automatic thread rolling machine shipments

Thread Rolling Machine Industry Applications

- Automotive sector uses thread rolling machinefor engine and transmission components

• Aerospace industry relies on thread rolling machinefor high-strength fasteners

• Construction equipment manufacturers employ roller threading machine for structural bolts

• Plumbing industry utilizes roller threading machine for pipe fittings production

• Electronics manufacturers use automatic thread rolling machine for precision screws

Thread Rolling Machine Maintenance Guidelines

- Regular lubrication schedule for thread rolling machinemoving parts

• Periodic inspection of roller threading machinedies for wear and damage

• Alignment checks for automatic thread rolling machine critical components

• Electrical system maintenance for thread rolling machine control panels

• Professional training recommended for roller threading machine operators

Automatic Thread Rolling Machine FAQs

What maintenance does a thread rolling machine require?

- Thread rolling machinerequires regular lubrication, die inspection, and alignment checks

How long do roller threading machine dies last?

- Roller threading machinedies typically last for 100,000-500,000 cycles depending on material

Can automatic thread rolling machine handle different materials?

- Automatic thread rolling machinecan process various metals including steel, aluminum, and brass

What safety features does thread rolling machine have?

- Modern thread rolling machineincludes emergency stops, guards, and safety interlocks

How to choose proper roller threading machine capacity?

- Select roller threading machinebased on thread size range and production volume requirements

Welcome to Hebei Moto Machinery Trade Co., Ltd.

Nestled in Xingwan Town, Ren County—Xingtai City, Hebei Province, a region celebrated for its rich heritage in machinery manufacturing—Hebei Moto Machinery stands as a testament to decades of craftsmanship and innovation. With over 20 years of dedicated expertise in the industry, we have established ourselves as a leading producer of thread rolling machines and diameter reducing machines, combining technical excellence with a deep understanding of global market needs.

At the core of our success lies our unwavering commitment to quality. Our products undergo stringent testing and adhere to the highest international standards, supported by our ISO 9001 certification for quality management. This ensures that every machine we deliver—from robust thread rolling solutions designed for precision threading in automotive and aerospace applications to efficient diameter reducing machines for metalworking and construction—exhibits durability, reliability, and superior performance.

What sets us apart is our ability to marry outstanding design with competitive pricing. We understand that our clients seek not just products, but solutions that enhance productivity and drive profitability. Our team of experienced engineers works tirelessly to innovate, ensuring our machines are not only technologically advanced but also cost-effective, helping businesses of all sizes gain a competitive edge in their markets.

Our global footprint speaks to our reputation. The trust of customers in Southeast Asia, the Middle East, Europe, Africa, and beyond is a testament to our dedication to professional service and customer satisfaction. From pre-sales consultation to after-sales support, we prioritize clear communication and tailored solutions, ensuring every client’s unique requirements are met with precision.

Backed by collaborations with renowned manufacturers and a state-of-the-art production facility, we consistently deliver results that exceed expectations. Our factory’s high praise from customers worldwide is a reflection of our integrity, craftsmanship, and relentless pursuit of excellence.

Whether you are expanding your production line, upgrading machinery, or seeking a reliable partner for specialized metalworking solutions, Hebei Moto Machinery is here to support you. Explore our comprehensive range of products at www.motetools.com , and discover how our expertise can help you achieve operational efficiency, market growth, and long-term success.

Where Innovation Meets Reliability – Your Partner in Machinery for the Next Generation.