-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

buy thread rolling machine

The Growing Demand for Thread Rolling Machines A Comprehensive Overview

In the fast-paced world of manufacturing, efficiency and precision are paramount. One of the critical processes in the production of fasteners and similar components is thread rolling. As industries increasingly seek to enhance productivity and product quality, the demand for thread rolling machines has surged. This article explores the significance of these machines, their benefits, and the factors driving their popularity.

The Growing Demand for Thread Rolling Machines A Comprehensive Overview

Another notable benefit of thread rolling machines is their efficiency. These machines can produce high volumes of threaded parts in a fraction of the time it would take traditional machining methods. For manufacturers looking to optimize production rates and minimize costs, investing in a thread rolling machine can lead to significant savings in both time and resources. Additionally, thread rolling results in minimal waste, as it utilizes a larger percentage of the raw material compared to cutting methods, where material is often discarded as chips.

buy thread rolling machine

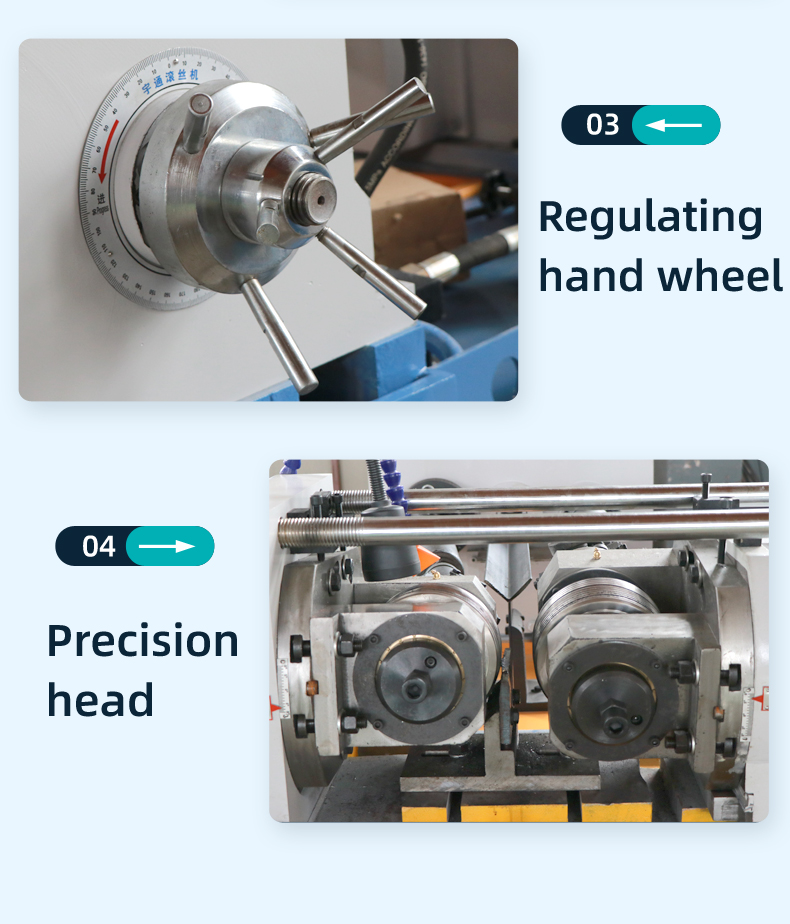

The advancements in technology have further propelled the evolution of thread rolling machines. Modern machines are equipped with sophisticated controls and automation, allowing for precise adjustments and consistent product quality. Features such as programmable settings and advanced monitoring systems enable manufacturers to meet stringent quality standards and reduce the risk of errors. As industries continue to embrace Industry 4.0, the integration of smart technologies into thread rolling machines has become increasingly common, enhancing their versatility and effectiveness.

The increasing interest in sustainable manufacturing practices has also contributed to the rise of thread rolling machines. With growing awareness surrounding environmental impact, businesses are seeking methods that not only improve efficiency but also reduce their ecological footprint. The cold-forming process of thread rolling consumes less energy and produces fewer emissions compared to traditional machining processes, making it a more eco-friendly option.

As industries expand globally, the demand for reliable and efficient manufacturing processes continues to grow. Regions such as Asia-Pacific, North America, and Europe are witnessing significant investments in thread rolling technology. The rise of small and medium-sized enterprises (SMEs) in these regions is also driving the demand, as these businesses increasingly adopt advanced manufacturing techniques to remain competitive.

In conclusion, the growing demand for thread rolling machines reflects the broader trends in the manufacturing industry a focus on efficiency, quality, and sustainability. These machines not only enhance the strength and precision of threaded components but also offer significant operational advantages. As technology continues to evolve, we can expect thread rolling machines to play an even more critical role in shaping the future of manufacturing. For companies looking to stay ahead, investing in this technology is not just a trend—it's a strategic move towards a more efficient and sustainable production process.