-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

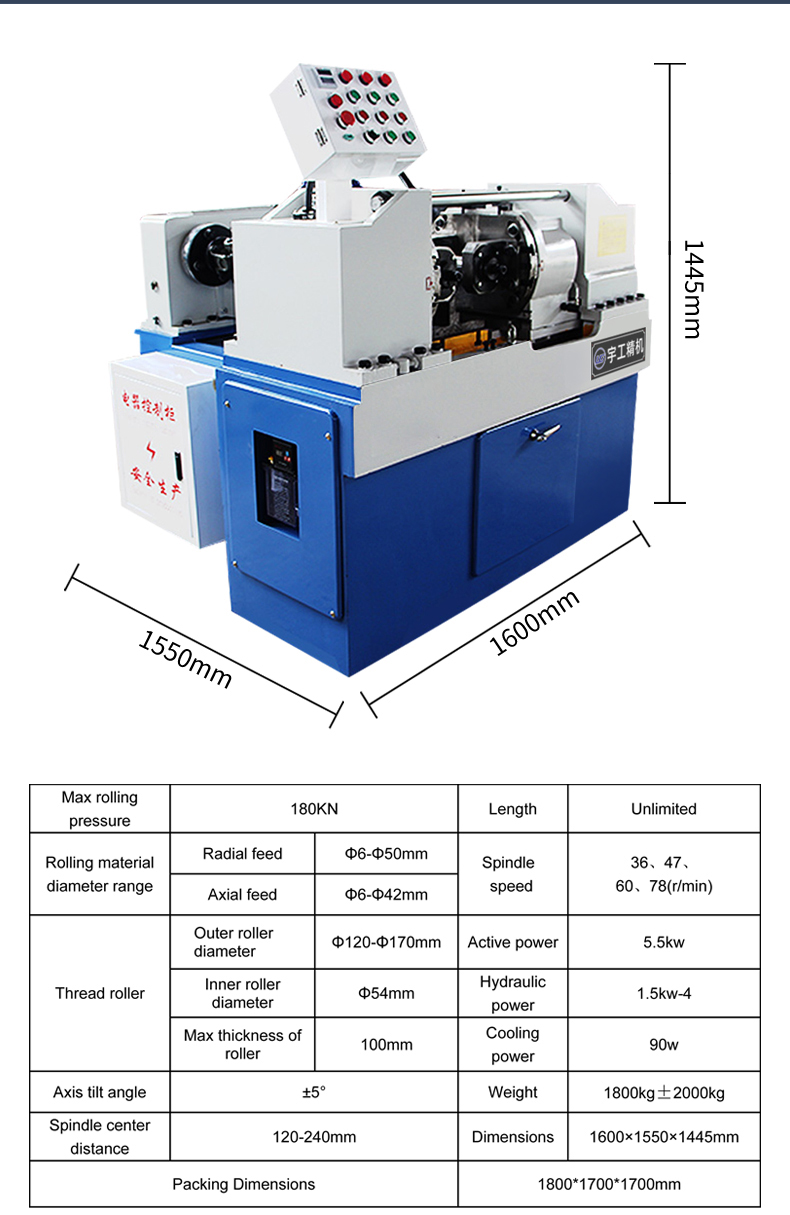

China's Advanced Screw Thread Rolling Machinery for Precision Manufacturing Solutions

The Role of Screw Thread Rolling Machines in Manufacturing

In the realm of manufacturing, specifically in the production of threaded fasteners, the importance of screw thread rolling machines cannot be overstated. These machines are designed to produce precise and high-quality screw threads with efficiency and speed, playing a crucial role in various industries ranging from automotive to aerospace and construction.

Understanding Screw Thread Rolling

Screw thread rolling is a cold-forming process that involves the shaping of metal into a desired thread form without the need for cutting. This method stands apart from traditional machining processes due to its ability to enhance the material properties of the workpiece. During rolling, the grains of the metal are reoriented, which can lead to improved strength and durability in the final product. The main advantage of this process lies in its efficiency, as it can produce threads at a much faster rate and with less material waste compared to cutting methods.

The machines used for this process encompass various types, including cylindrical, flat, and planetary thread rolling machines. Each type is designed to cater to different thread sizes and shapes, allowing manufacturers to meet specific requirements of their customers.

The Advantages of Using Rolling Machines

1. Increased Strength One of the primary advantages of using screw thread rolling machines is the enhanced strength of the threaded products. The cold-forming process results in a finer grain structure, which translates to improved tensile strength and fatigue resistance.

2. Cost-Effectiveness By reducing material wastage and increasing production speeds, screw thread rolling machines represent a cost-effective solution for manufacturers. The efficiency of these machines can lead to significant savings in both raw materials and labor costs.

3. Precision and Consistency Modern screw thread rolling machines are equipped with advanced technology that ensures high precision and consistency in thread dimensions. This level of accuracy is crucial for applications where proper engagement between threads is critical to ensure safety and reliability.

china screw thread rolling machine

4. Versatility These machines are capable of producing various types of threads, such as metric, UN, and custom profiles. This versatility makes them valuable in industries with diverse requirements, allowing manufacturers to adapt to changing demands quickly.

The Applications of Screw Thread Rolling Machines

Screw thread rolling machines are employed across various sectors. In the automotive industry, they are used to create fasteners for engines, transmissions, and structural components. In aerospace manufacturing, the demand for lightweight yet strong threaded components necessitates the use of advanced rolling techniques. Additionally, industries such as construction rely on these machines for producing high-strength nuts and bolts used in critical structural applications.

Technological Advancements

Recent advancements in technology have further enhanced the capabilities of screw thread rolling machines. The integration of computer numerical control (CNC) has allowed for greater automation and precision in the manufacturing process. Operators can input specific parameters into the machine, ensuring that each thread produced meets the exacting standards required for modern applications.

Moreover, advancements in materials science have led to the development of new alloys that can be utilized in conjunction with thread rolling technology, enabling manufacturers to produce components that meet specific weight and strength criteria.

Conclusion

In conclusion, screw thread rolling machines are indispensable in the modern manufacturing landscape. Their ability to produce high-strength, precise, and cost-effective threaded components has solidified their role in various industries. As technology continues to evolve, the potential for screw thread rolling machines to contribute to innovation and efficiency in manufacturing will only grow, making them a key asset for companies aiming to maintain competitiveness in a global market.