-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

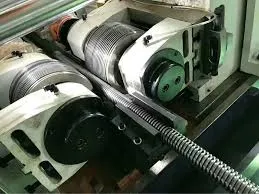

custom thread rolling machine flat die

Custom Thread Rolling Machine with Flat Die Revolutionizing Precision Manufacturing

In today’s competitive manufacturing landscape, precision and efficiency are paramount. One of the innovative technologies that has emerged to meet the demands of modern production processes is the custom thread rolling machine, particularly those utilizing flat die technology. These machines have transformed the way threads are produced, allowing for tighter tolerances, superior strength, and enhanced production speeds.

What is Thread Rolling?

Thread rolling is a cold-forming process that involves deforming metal into desired thread shapes without removing any material. This process is favored for its ability to produce high-strength threads with exceptional surface finishes. Unlike traditional machining methods, which cut material away to form threads, thread rolling utilizes mechanical pressure to shape the material, preserving its integrity and density.

Advantages of Flat Die Technology

Flat die thread rolling machines operate using two flat dies that press against a workpiece to form threads. This approach offers several key advantages

1. Increased Production Rates Flat die thread rolling is known for its rapid cycle times. The ability to produce multiple threads simultaneously significantly reduces production time, enabling manufacturers to meet high-volume demands with ease.

2. Cost-Effectiveness By reducing the amount of scrap material produced and minimizing energy consumption, flat die machines contribute to lower operational costs. The durability of the dies also means less frequent replacements, further improving the cost-efficiency of the process.

custom thread rolling machine flat die

3. Enhanced Strength and Durability Threads produced by the rolling process exhibit superior mechanical properties compared to cut threads. The cold working of the material increases its strength due to strain hardening, making rolled threads less likely to fail under tension.

4. Superior Surface Finish The thread rolling process imparts a smooth surface finish, which reduces the need for additional machining or surface treatments. This is particularly beneficial in applications where precision and appearance are critical.

Customization for Diverse Applications

One of the standout features of custom thread rolling machines is their adaptability. Manufacturers can customize the design of the dies to produce threads of various sizes, shapes, and configurations. This flexibility is particularly valuable in industries such as automotive, aerospace, and electronics, where specific thread profiles are necessary to meet stringent specifications.

By collaborating closely with clients, manufacturers can develop tailored solutions that not only meet industry standards but also enhance overall product performance. Whether it is a unique threading pattern for a specialized fastener or a specific material requirement, custom thread rolling machines can adjust to meet the specific needs of each project.

Conclusion

The custom thread rolling machine equipped with flat die technology represents a significant advancement in the field of precision manufacturing. Its ability to produce high-quality, strong, and cost-effective threaded components makes it an invaluable tool for various industries. As companies continue to seek ways to improve efficiency and quality in production processes, the adoption of advanced machinery like custom thread rolling machines will undoubtedly play a pivotal role in shaping the future of manufacturing.

As the demand for precision-engineered products grows, the ability to harness the benefits of thread rolling through innovative machinery offers a competitive edge. Manufacturers who invest in this technology will find themselves better positioned to meet the challenges of tomorrow's manufacturing environment, driving productivity and innovation forward.