-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ינו . 14, 2025 12:05

Back to list

custom types of thread rolling machine

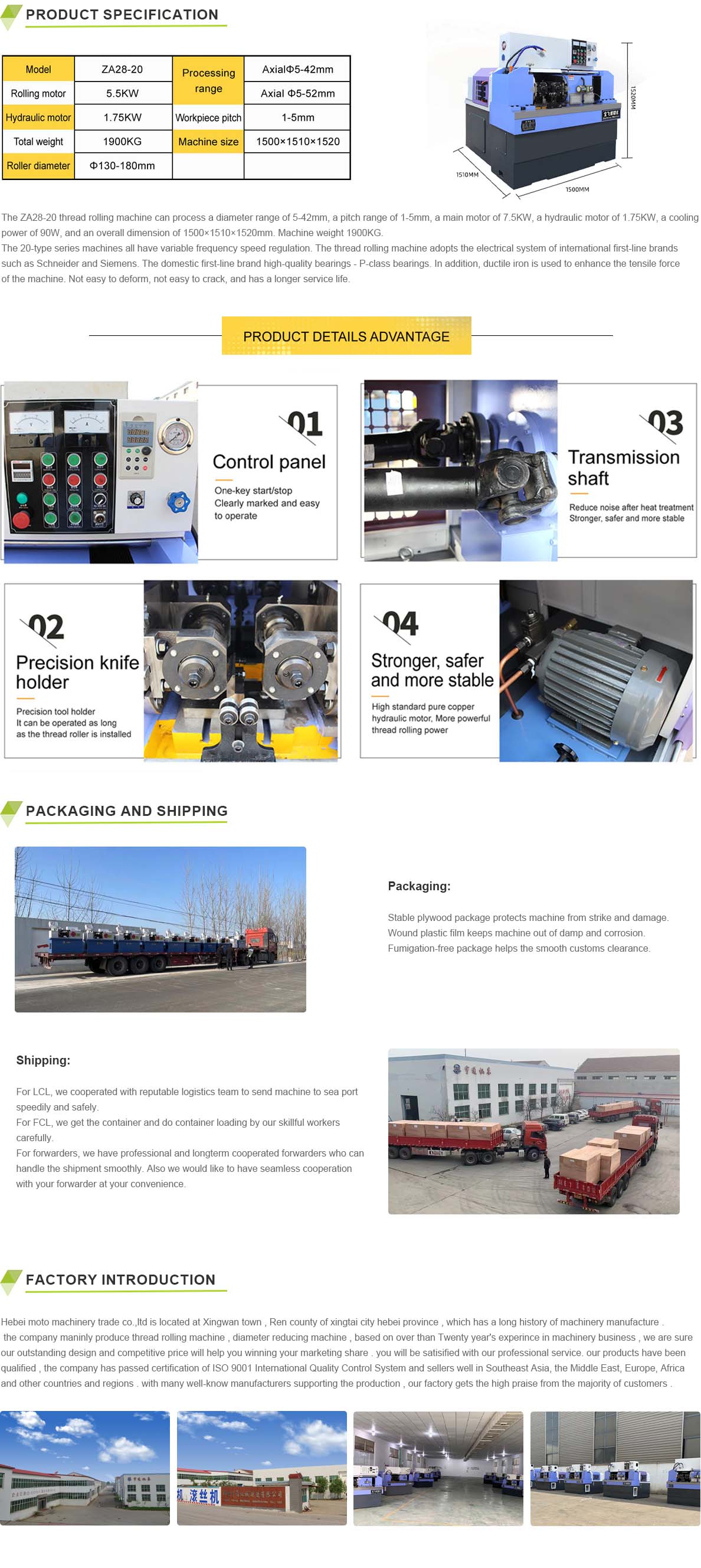

Custom thread rolling machines are at the forefront of innovation in manufacturing, providing unique solutions tailored to meet specific industrial needs. These versatile machines are designed to deliver exceptional performance by accommodating a wide range of thread geometries, sizes, and materials, offering immense benefits to various sectors including automotive, aerospace, and construction.

The authority that manufacturers of custom thread rolling machines command comes not only from their technical proficiency but also from their innovative approaches to problem-solving. For example, machines are often equipped with advanced controls and monitoring systems that allow for real-time adjustments and troubleshooting. This technological integration empowers operators to maintain peak machine performance, reducing downtime and enhancing productivity. From a trustworthiness perspective, custom thread rolling machines are developed with rigorous testing and quality assurance protocols. Manufacturers often offer comprehensive support and training to ensure seamless operation and maintenance of the machines. This commitment to quality and service reinforces trust and builds long-term relationships with clients, who rely on these machines for critical production operations. Furthermore, the development of custom thread rolling machines often involves collaboration with clients to deeply understand and address their unique challenges. This partnership approach ensures that the end solutions not only meet but exceed the expectations, delivering machines that are not just functional but also instrumental in advancing the client's business objectives. In conclusion, custom thread rolling machines represent a pinnacle of industrial machinery innovation, merging the intricate knowledge of metallurgy with cutting-edge engineering to deliver unmatched performance. These machines are more than just tools; they are strategic assets that enhance a company's production capabilities. By investing in custom solutions, businesses can position themselves at the forefront of their industries, ready to meet the demands of today's competitive markets with confidence and precision.

The authority that manufacturers of custom thread rolling machines command comes not only from their technical proficiency but also from their innovative approaches to problem-solving. For example, machines are often equipped with advanced controls and monitoring systems that allow for real-time adjustments and troubleshooting. This technological integration empowers operators to maintain peak machine performance, reducing downtime and enhancing productivity. From a trustworthiness perspective, custom thread rolling machines are developed with rigorous testing and quality assurance protocols. Manufacturers often offer comprehensive support and training to ensure seamless operation and maintenance of the machines. This commitment to quality and service reinforces trust and builds long-term relationships with clients, who rely on these machines for critical production operations. Furthermore, the development of custom thread rolling machines often involves collaboration with clients to deeply understand and address their unique challenges. This partnership approach ensures that the end solutions not only meet but exceed the expectations, delivering machines that are not just functional but also instrumental in advancing the client's business objectives. In conclusion, custom thread rolling machines represent a pinnacle of industrial machinery innovation, merging the intricate knowledge of metallurgy with cutting-edge engineering to deliver unmatched performance. These machines are more than just tools; they are strategic assets that enhance a company's production capabilities. By investing in custom solutions, businesses can position themselves at the forefront of their industries, ready to meet the demands of today's competitive markets with confidence and precision.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025