-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

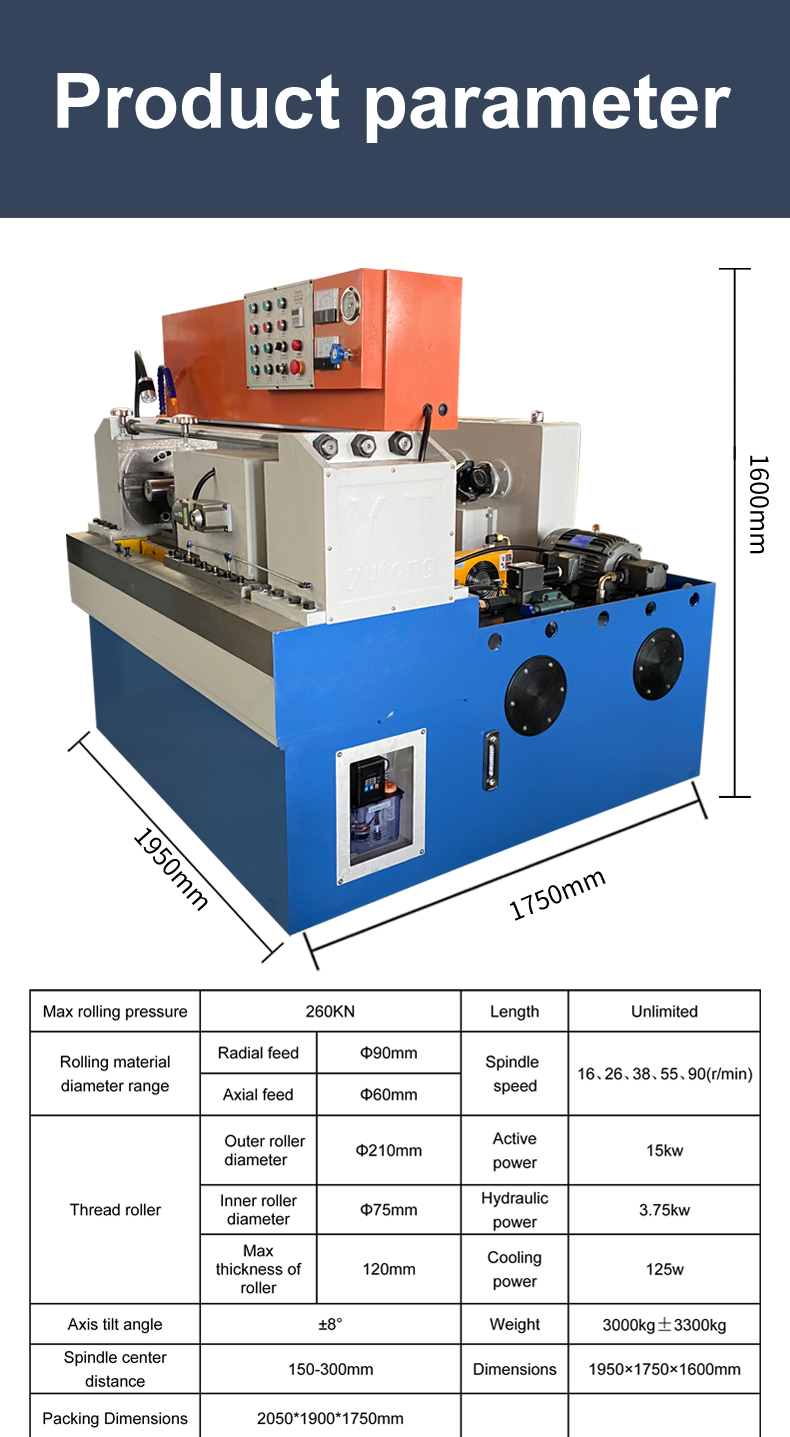

Custom Circular Thread Rolling Machines for Precision Manufacturing Solutions

The Evolution and Significance of Custom Circular Thread Rolling Machines

In the realm of industrial manufacturing, the precision and efficiency of production processes are paramount. Among the advanced technologies that enhance these processes is the custom circular thread rolling machine. This innovative machinery has revolutionized how threads are fabricated, offering significant advantages over traditional methods. This article explores the evolution of thread rolling machines, their mechanisms, customization capabilities, and their impact on various industries.

The Evolution of Thread Rolling Technology

Thread rolling technology has a rich history that dates back to the early 20th century when manufacturers sought more efficient ways to produce threaded fasteners. Initially, threads were cut or machined, a process that generated considerable waste in terms of raw materials and time. However, as the demand for high-quality threaded products grew, engineers began developing thread rolling machines that could create threads through deformation rather than removal.

By using pressure to displace material, these machines produced threads with greater strength and superior surface finishes. The early designs were rudimentary, but advancements over the decades have led to sophisticated machines equipped with advanced controls and automation. Today, custom circular thread rolling machines represent the zenith of this technology, enabling manufacturers to tailor their production processes to specific needs.

Mechanisms of Custom Circular Thread Rolling Machines

Custom circular thread rolling machines operate on the principle of cold working, where a cylindrical workpiece is rotated while being pressed between two specialized dies. These dies are precisely engineered to impart the desired thread profile onto the material. The circular motion allows for uniform pressure distribution, resulting in threads that meet strict performance and dimension specifications.

One of the critical features of custom thread rolling machines is their versatility. They can accommodate various materials, including steel, aluminum, and plastic, making them suitable for diverse applications. Additionally, the machines can be configured to produce different thread sizes and profiles, from fine to coarse threads, depending on the needs of the manufacturer.

Customization Capabilities

custom circular thread rolling machine

The ability to customize thread rolling machines is one of their most significant benefits. Manufacturers can work with engineers to design bespoke machines tailored to their specific production goals. This customization can involve modifications to the dies, adjustments in the rolling process, and the integration of automation systems for increased efficiency.

Custom machines enable manufacturers to produce unique thread designs that may be required in specialized applications, such as aerospace, automotive, and electronics. Furthermore, customized machines can help optimize production rates, reduce operational costs, and minimize waste, ultimately leading to higher profit margins.

Impact on Industries

The significance of custom circular thread rolling machines cannot be overstated. Industries that rely on high-quality threaded components, such as manufacturing, construction, and aerospace, benefit tremendously from these machines. Their ability to produce strong, reliable threads not only meets industry standards but often exceeds them, ensuring the safety and longevity of the products they manufacture.

Moreover, the efficiency of these machines allows for shorter production cycles. Assembly lines can operate more smoothly, and manufacturers can respond more quickly to market demands. As a result, companies that invest in custom thread rolling technology often find themselves better positioned to compete in an increasingly globalized marketplace.

Conclusion

In conclusion, custom circular thread rolling machines are a critical innovation in the manufacturing sector. Their evolution has marked a significant shift from traditional thread-making processes to efficient, high-quality production systems. By offering customization, these machines empower manufacturers to meet specific demands while enhancing quality and driving down costs.

As industries continue to evolve and face new challenges, the role of custom circular thread rolling machines will undoubtedly grow, paving the way for advancements that could redefine manufacturing standards in the years to come. As companies strive for efficiency and precision, investing in such technology will remain a cornerstone of success in the manufacturing landscape.