-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Supplier of High-Speed Thread Rolling Machines for Efficient Manufacturing Solutions

The Evolution and Importance of High-Speed Thread Rolling Machines

In today’s manufacturing industry, the demand for precision and efficiency has led to significant advancements in production technologies. Among these innovations, high-speed thread rolling machines have emerged as essential tools for producing threads of exceptional quality. These machines are crucial for various industries, including automotive, aerospace, and construction, where strong and durable threaded components are required.

What is a High-Speed Thread Rolling Machine?

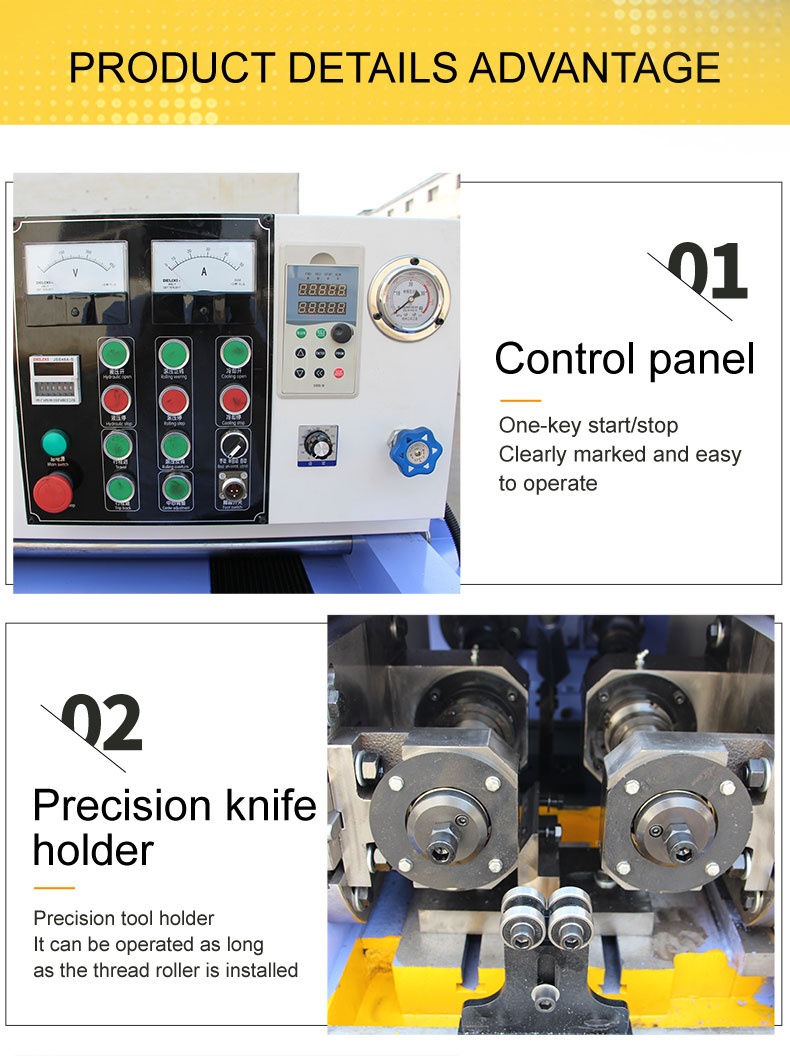

High-speed thread rolling machines utilize a process known as thread rolling, where a cylindrical workpiece is passed between two rolling dies. This method deforms the material to create threads through a cold-forming process. Unlike traditional machining methods that remove material to create threads, thread rolling compresses the material, resulting in stronger and more precise threads. The primary advantage of high-speed machines lies in their ability to produce a large volume of threaded parts quickly and consistently, thereby improving productivity rates in manufacturing settings.

Benefits of High-Speed Thread Rolling Machines

1. Enhanced Strength and Durability One of the most significant advantages of thread rolling over traditional machining is the grain flow of the material. The cold-forming process preserves the integrity of the material, resulting in threads that are often stronger and more resistant to fatigue. This makes them ideal for high-stress applications.

2. Increased Production Speed High-speed thread rolling machines can operate at significantly faster rates than conventional machining processes. This allows manufacturers to produce more parts in a shorter time frame, reducing labor costs and increasing overall operational efficiency.

3. Cost-Effectiveness Due to their efficiency and ability to produce high volumes of components quickly, high-speed thread rolling machines can substantially lower the cost per unit. While the initial investment in these machines may be higher, the long-term savings in labor and material costs make them an attractive option for manufacturers.

4. Consistency and Accuracy High-speed machines are designed to produce consistent and accurate threaded components. With precise controls and advanced engineering, these machines minimize the variations that can occur with manual or traditional processes. This precision results in less waste and lower rework rates.

5. Versatility Modern high-speed thread rolling machines can be adapted to produce a wide range of thread sizes and types, making them versatile tools for various manufacturing needs. This adaptability allows companies to meet diverse customer demands without the need for multiple specialized machines.

high speed thread rolling machine supplier

Choosing the Right Supplier

When seeking a high-speed thread rolling machine supplier, it is essential to evaluate several factors to ensure you get the best equipment for your needs. Here are some considerations

1. Experience and Reputation Look for suppliers with a proven track record in the industry. An experienced supplier will not only provide high-quality machines but also offer valuable insights and support regarding the technology.

2. Technical Support and Service A reputable supplier should provide comprehensive technical support and service options. This includes installation, maintenance, and troubleshooting to minimize downtime in your production process.

3. Customization Options Different applications require different specifications. Find a supplier that offers customization to meet your specific requirements, ensuring that the machine operates efficiently within your production line.

4. Quality Assurance Ensure that the supplier adheres to stringent quality standards and can provide certifications. Quality assurance in the manufacturing process of the machines will reflect in their performance and longevity.

5. Customer Reviews and Testimonials Research customer experiences to gauge the reliability of the supplier’s products and services. Positive testimonials can indicate a supplier’s commitment to customer satisfaction and product excellence.

Conclusion

High-speed thread rolling machines play a pivotal role in modern manufacturing, offering significant advantages in strength, efficiency, and cost-effectiveness. As industries continue to evolve, the demand for high-quality threaded components will only grow, making these machines indispensable in the production process. By selecting the right supplier, manufacturers can leverage the benefits of high-speed thread rolling technology to stay competitive in an ever-changing market. Embracing this technology not only enhances productivity but also contributes to the overall quality and reliability of products, ultimately leading to greater customer satisfaction.