-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

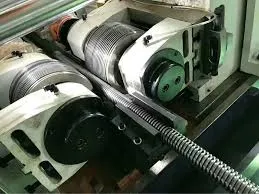

Custom Roll Thread Machine Cost and Pricing Details for Various Models

Understanding the Pricing of Custom Roll Thread Machines

In the realm of manufacturing and production, the precision of threading can significantly influence the quality of the final products. Custom roll thread machines have emerged as a crucial tool for many industries. These machines guarantee high precision while ensuring efficiency in production processes. However, companies often find themselves grappling with questions regarding the pricing of these custom machines. Understanding the factors affecting the price of custom roll thread machines can help businesses make informed decisions.

Custom roll thread machines are specialized equipment designed for the creation of threads on various materials. Unlike traditional cutting methods, rolling threads involves deforming the material, which can produce threads without removing material. This rolling process not only enhances the strength of the threads due to cold working but also minimizes waste. Given these advantages, the investment in a custom roll thread machine can be substantial.

The price of a custom roll thread machine can vary greatly depending on several factors

1. Specifications and Features The most significant aspect that influences the price is the machine's specifications. Different machines come with various capabilities, such as speed, size, materials they can handle, and the complexity of the threading profiles they can produce. More complex machines capable of handling a wider range of materials and producing intricate thread designs generally come with higher price tags. Therefore, it's crucial for businesses to assess their specific needs and choose a machine that aligns with them without overspending.

custom roll thread machine price

2. Customization As the name suggests, custom roll thread machines are often tailored to meet specific production requirements. Customization introduces additional costs, reflecting the engineering and design work necessary to adapt the machine for unique applications. While custom features can lead to enhanced productivity, they may also escalate expenses. Companies should weigh the benefits of customization against their budget constraints to find an optimal solution.

3. Brand and Manufacturer The reputation of the manufacturer can also greatly affect the pricing of roll thread machines. Well-established brands with proven reliability and customer service may charge a premium for their products. However, investing in a reputable brand often ensures better quality, warranty options, and long-term customer support, which can be advantageous in the long run.

4. Additional Costs When budgeting for a custom roll thread machine, companies should consider ancillary costs that may not be immediately apparent. These can include shipping, installation, training for operators, maintenance contracts, and even downtime during installation. It’s essential to factor in these additional expenses to avoid budget overruns and ensure a clear picture of the overall investment.

5. Market Trends and Demand Like many industrial products, the pricing of custom roll thread machines can be influenced by market trends and demand. Economic conditions, supply chain challenges, and advancements in technology can all impact machine prices. Staying informed about market dynamics can help companies make timely and cost-effective purchasing decisions.

In conclusion, the investment in a custom roll thread machine is not insignificant, but the benefits of enhanced production efficiency and product quality can outweigh the costs. By understanding the various factors that influence pricing—such as machine specifications, customization, brand reputation, additional costs, and market trends—businesses can make informed decisions that align with their operational needs and budget constraints. As industries continue to evolve, the demand for high-quality threading solutions will only increase, making it essential for manufacturers to choose the right equipment wisely. With careful consideration and strategic planning, companies can pave the way for successful production outcomes.