-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

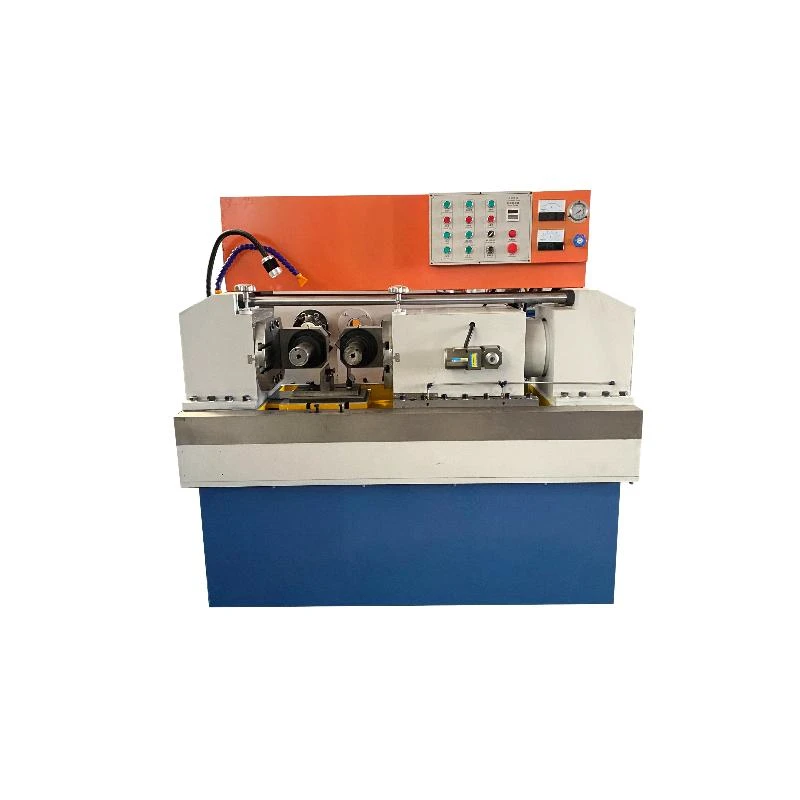

High Precision Rolling Thread Machines for Superior Quality Production Solutions

The Importance of High-Quality Roll Thread Machines in Modern Manufacturing

In the dynamic landscape of manufacturing, precision and efficiency have become the cornerstones of competitive advantage. Among the myriad of machines that facilitate the production process, high-quality roll thread machines stand out for their unparalleled ability to create strong, durable threads seamlessly. These machines have revolutionized the way components are manufactured in various industries, including automotive, aerospace, and general manufacturing.

Understanding Roll Threading

Roll threading is a process that involves forming threads on a workpiece by deforming the material through the application of high pressure by hardened rollers. Unlike traditional cutting methods, which remove material to create threads, roll threading retains more material, resulting in stronger threads with superior fatigue resistance. This is particularly vital in applications that demand high reliability under stress.

Advantages of High-Quality Roll Thread Machines

1. Enhanced Strength and Durability One of the most significant advantages of using high-quality roll thread machines is their ability to produce threads that are inherently stronger. The cold-forming process aligns the grain structure of the material, which enhances the overall tensile strength of the threaded component. This is crucial for applications where failure is not an option, such as in critical aerospace or automotive parts.

2. Increased Production Efficiency High-quality roll thread machines are designed for speed and efficiency. They can produce threaded components at a faster rate than traditional thread cutting machines, thereby reducing cycle times and increasing overall productivity. With advanced automation features, these machines can operate with minimal human intervention, leading to lower labor costs and higher output.

3. Reduction in Material Waste In manufacturing, material waste is a significant concern. Roll threading minimizes waste by utilizing a process that retains more of the original material. This not only reduces costs associated with raw materials but also lowers the environmental impact of production. As companies strive for sustainability, the low-waste operation of roll thread machines becomes an attractive option.

high quality roll thread machine

4. Versatility in Applications High-quality roll thread machines can accommodate a wide variety of materials, including metals, plastics, and composites. This versatility makes them suitable for numerous applications across different industries. Manufacturers can easily switch between different thread sizes and types without the need for extensive retooling, thus maximizing the utility of the machines.

5. Quality Consistency Automated roll thread machines ensure consistent thread quality across all manufactured components. This uniformity is essential for maintaining product standards and for the compatibility of parts within assemblies. Manufacturers can achieve tighter tolerances and reduced variability, leading to a more reliable product.

Selecting the Right Roll Thread Machine

When investing in a roll thread machine, several factors must be considered to ensure it meets production needs. These include the machine's specifications, such as its capacity, speed, and the range of materials it can handle. Additionally, assessing the manufacturer’s reputation, service support, and warranty options can help in making a more informed decision.

Furthermore, features such as programmable controls and the ability to integrate with existing production systems can provide added value. As Industry 4.0 technologies continue to evolve, high-quality roll thread machines that offer connectivity and data analytics capabilities will enable manufacturers to optimize their operations further.

Conclusion

In conclusion, high-quality roll thread machines are essential tools in modern manufacturing, offering a multitude of benefits that enhance production efficiency, reduce waste, and improve product quality. As industries continue to demand higher standards of manufacturing and sustainability, these machines will play an increasingly vital role in meeting those challenges. Embracing the capabilities of roll thread machines can lead to superior manufacturing outcomes and a stronger competitive edge in the market.