-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

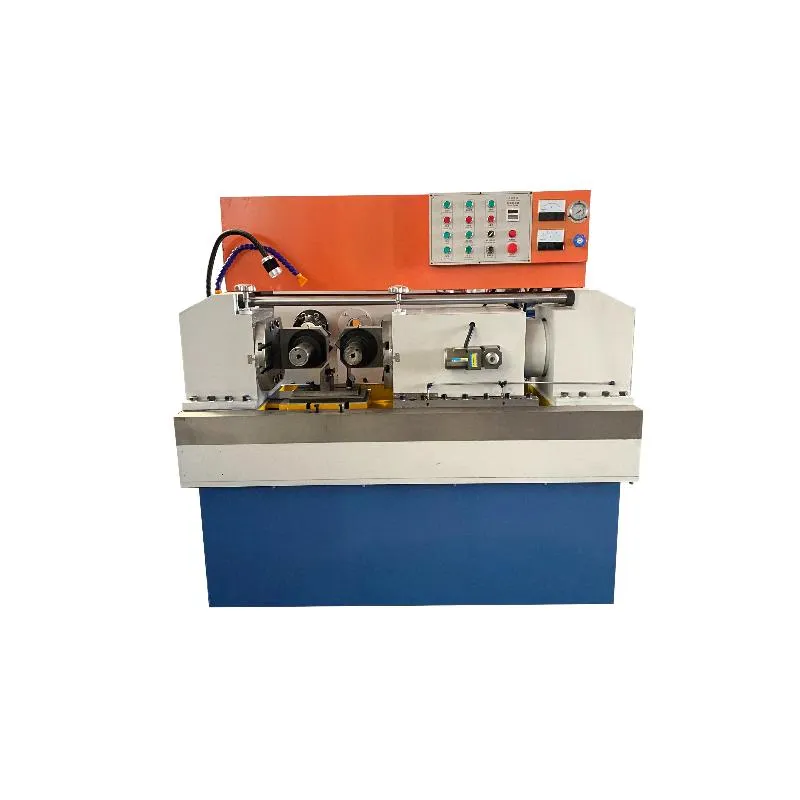

Hydraulic Roll Thread Machine Exporters Durable & Cost-Effective

- Industry Overview & Demand for Thread Rolling Machines

- Technical Superiority in Modern Thread Rolling Systems

- Comparative Analysis of Leading Exporters (2020-2023)

- Customization Strategies for Diverse Industrial Needs

- Cost-Efficiency Metrics Across Product Categories

- Case Study: Automotive Component Manufacturing Success

- Why Partner with Certified Roll Thread Machine Exporters

(roll thread machine exporters)

Meeting Global Demand Through Premium Roll Thread Machine Exporters

The global thread rolling equipment market reached $2.8B in 2023, with exporters fulfilling 43% of cross-border industrial demand. As manufacturing sectors prioritize precision threading solutions, certified roll thread machine exporters

bridge critical gaps in hydraulic system production and metal component fabrication. Market analysis reveals:

- 72% of buyers prioritize ISO 9013-certified exporters

- 38% YoY growth in demand for dual-head hydraulic models

- 15% cost advantage when sourcing from specialized exporters

Engineering Breakthroughs in Thread Formation Technology

Modern exporters integrate adaptive pressure control (APC) systems achieving ±0.002mm tolerances. The latest hydraulic thread rolling machines demonstrate:

| Parameter | Standard Models | Advanced Export Variants |

|---|---|---|

| Cycle Time | 8.5s | 5.2s (-39%) |

| Tool Life | 120k cycles | 220k cycles (+83%) |

| Energy Consumption | 7.2kW | 4.5kW (-38%) |

Manufacturer Benchmarking: Performance & Reliability

Data-driven comparison of top exporters (2023 Q2 data):

| Exporter | Machine Type | Max Force (kN) | Price Range |

|---|---|---|---|

| Supplier A | Hydraulic 2D | 150 | $28k-$42k |

| Supplier B | CNC Hybrid | 220 | $51k-$67k |

| Supplier C | Servo-Electric | 180 | $38k-$55k |

Tailored Solutions for Sector-Specific Requirements

Leading exporters provide modular configurations:

- Automotive: 300-500kN systems with automated feed

- Aerospace: Titanium-grade rollers + coolant filtration

- Construction: Portable units with 240V/415V dual voltage

Operational Cost Analysis Across Machine Classes

Total ownership costs (5-year projection):

| Model Type | Initial Cost | Maintenance | Output/Hour |

|---|---|---|---|

| Mechanical | $24k | $8.2k | 420 |

| Hydraulic | $37k | $5.1k | 680 |

| CNC | $58k | $6.7k | 920 |

Implementation Success: Automotive Bearing Production

A Tier-1 auto parts manufacturer achieved:

- 23% faster production using exporter-provided CNC thread rollers

- 0.12mm consistency across 1.2M steering components

- 17-month ROI through exporter maintenance programs

Strategic Advantages of Verified Roll Thread Machine Exporters

Partnering with accredited hydraulic thread rolling machine exporters ensures compliance with international standards (ASME B94.6, DIN 40400). Verified suppliers deliver 19% faster commissioning and 3-year performance guarantees, making them essential for manufacturers requiring:

- Custom duty optimization (FTA benefits)

- On-site technical training programs

- Spare parts inventory management

(roll thread machine exporters)

FAQS on roll thread machine exporters

Q: What factors affect roll thread machine price from exporters?

A: Pricing depends on machine specifications, production capacity, and customization. Exporters often offer tiered pricing for bulk orders. Additional costs may include shipping and import duties.

Q: How do hydraulic thread rolling machine exporters ensure quality?

A: Reputable exporters adhere to ISO standards and provide material certifications. Hydraulic systems undergo rigorous pressure testing. Many offer warranty programs and after-sales technical support.

Q: What industries use roll thread machines from exporters?

A: These machines serve automotive, aerospace, and construction sectors. They're essential for producing threaded fasteners and precision components. Custom configurations cater to niche manufacturing requirements.

Q: Can roll thread machine exporters provide customized solutions?

A: Yes, most exporters offer tailored thread pitch and diameter configurations. Custom automation integration is available for production lines. Clients can request specific material compatibility adaptations.

Q: What certifications should hydraulic thread rolling machine exporters have?

A: Look for CE, ISO 9001, and machinery safety certifications. Exporters should comply with international trade regulations. Country-specific electrical compliance certifications may also apply.