-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

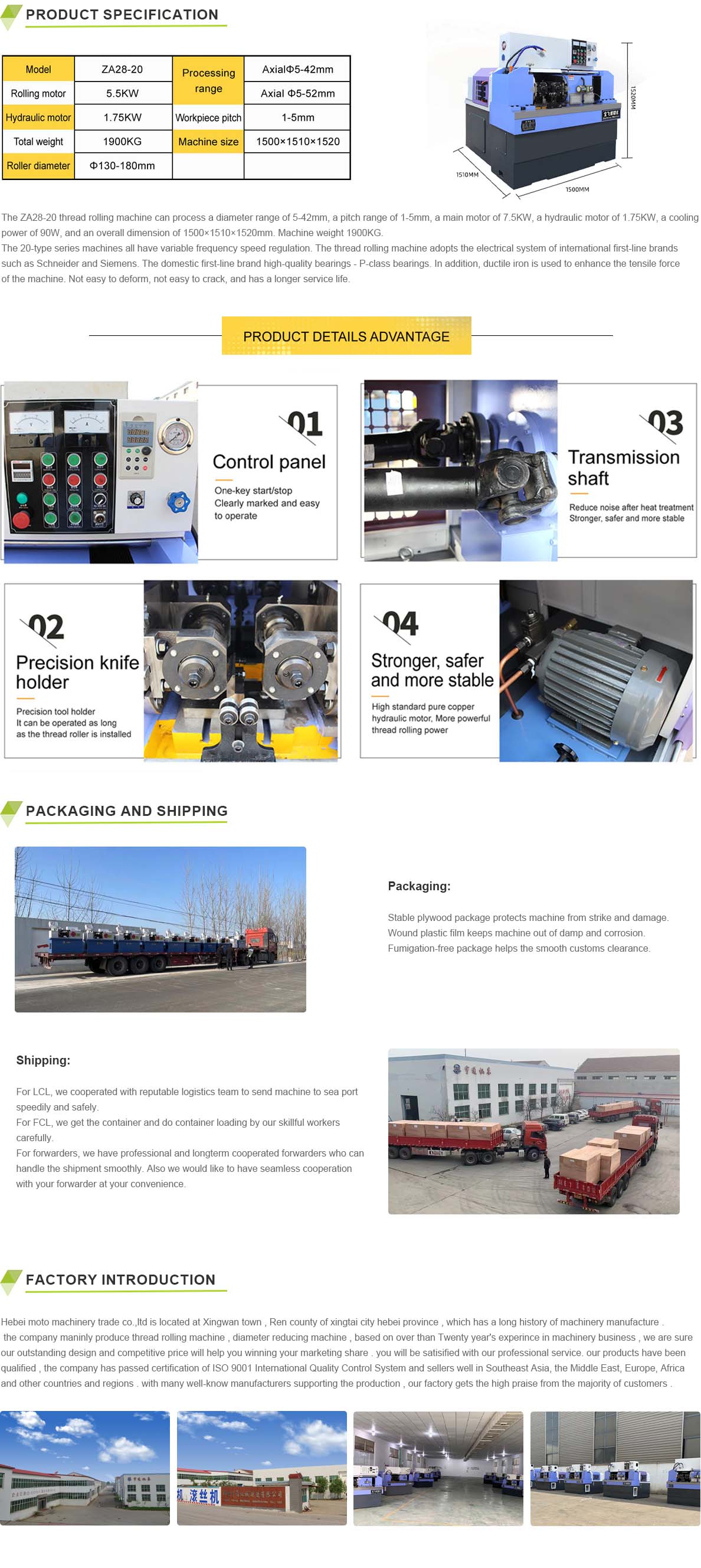

High-Quality Hydraulic Thread Rolling Machines for Precision Manufacturing

Hydraulic thread rolling machines are essential tools in the manufacturing industry, specifically designed for the precision creation of threaded fasteners and other cylindrical products. Utilizing hydraulic power, these machines achieve high efficiency and accuracy in rolling threads, making them a popular choice for manufacturers who prioritize quality and performance.

One of the key advantages of hydraulic thread rolling machines is their ability to produce threads without the need for cutting tools. This process, known as cold forming, involves the deformation of material to produce the desired thread profile. Unlike traditional machining methods, which can waste material and require extensive tooling, thread rolling minimizes scrap and provides a more environmentally friendly option. Additionally, the cold forming process increases the strength of the threads, as the molecular structure of the material is enhanced under pressure.

The versatility of hydraulic thread rolling machines allows them to be used for a variety of applications. They can efficiently produce different thread sizes and profiles, making them ideal for industries such as automotive, aerospace, and construction. Hydraulic machines can also accommodate a wide range of materials, from soft metals like aluminum to harder alloys, providing manufacturers with the flexibility needed to meet their production requirements.

hydraulic thread rolling machine products

Moreover, advances in technology have led to the development of more sophisticated hydraulic thread rolling machines equipped with computer numerical control (CNC) systems. These systems enhance precision by automating the rolling process, allowing for intricate designs and tighter tolerances. As a result, manufacturers are seeing reduced lead times and improved production efficiency, which ultimately contributes to lower overall costs.

Maintenance is another important consideration when it comes to hydraulic thread rolling machines. Regular inspections and upkeep are necessary to ensure these machines operate smoothly and efficiently. Manufacturers are often encouraged to invest in training for their personnel to ensure they are well-versed in operating and maintaining the equipment.

In conclusion, hydraulic thread rolling machines play a vital role in modern manufacturing environments. Their efficiency, precision, and ability to produce high-quality threaded products make them indispensable in various industries. As technology continues to evolve, these machines are likely to become even more advanced, further solidifying their position in the marketplace. With a focus on sustainability and material efficiency, hydraulic thread rolling machines represent the future of fastener production.