-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

Bahasa inggris

Bahasa inggris -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Eco-Friendly Thread Rolling Tool

In today's manufacturing landscape, sustainability has evolved from a buzzword to an operational imperative. Amidst tightening environmental regulations and rising material costs, the thread rolling tool emerges as an unsung hero of eco-conscious production. Unlike traditional cutting methods that generate metal shavings and consume excessive energy, thread rolling reshapes metal through cold forming—a process requiring less power while producing zero waste chips. This method preserves raw materials and eliminates toxic coolants, making it inherently environmentally friendly. Industries from automotive to construction now prioritize these tools not just for their precision, but for their role in reducing carbon footprints. Leading this shift is Hebei Moto Machinery Trading Co., Ltd., a pioneer with 28 years of expertise in sustainable metal processing. Their dual-brand strategy—"Yugong" for rugged reliability and "Baofeiluo" for technological innovation—reflects a commitment to solutions that harmonize productivity with planetary stewardship. From reducing landfill waste to slashing energy consumption, the evolution of thread rolling represents a silent revolution where every rolled thread becomes a statement of ecological responsibility.

The Anatomy of an Eco-Conscious Thread Rolling Tool

At the core of sustainable manufacturing lies the thread rolling tool, a masterpiece of engineering that transforms metal billets into precision threads without subtractive processes. By applying controlled pressure through hardened dies, it induces plastic deformation that enhances grain structure, yielding threads with superior fatigue resistance. The eco-advantages are multifaceted:

- Zero Waste Generation: Unlike machining, no metal chips require disposal or recycling.

- Energy Efficiency: Cold forming consumes significantly less electricity than cutting operations.

- Longevity: Tools made from high-alloy steels endure millions of cycles, minimizing resource depletion.

Hebei Moto Machinery’s ISO 9001-certified facilities produce dies tempered to extreme hardness, ensuring decade-long service lives. Their proprietary surface treatments reduce friction, further lowering energy demands. For industries transitioning to green practices, these tools offer immediate environmental dividends—transforming raw materials into finished products with near-total material utilization.

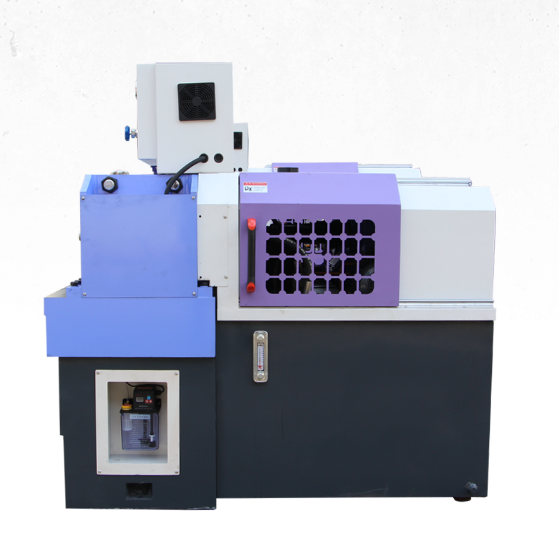

The Role of Small Thread Rolling Machines

When space constraints meet sustainability goals, the small thread rolling machine shines. Designed for workshops, repair centers, and job shops, these units deliver industrial-grade threading without industrial-scale energy consumption. Key features include:

- Minimal Footprint: Fitting within limited floor areas while maintaining robust output.

- Adaptive Operations: Handling diverse materials from stainless steel fasteners to brass fittings.

- Low Power Draw: Engineered motors that optimize energy use during idle and active cycles.

Hebei Moto Machinery’s "Baofeiluo" line exemplifies this category, featuring regenerative drives that recapture braking energy. Their machines integrate quick-change die systems, allowing rapid transitions between thread sizes without recalibration—reducing downtime and associated energy waste. For automotive suppliers or hardware manufacturers, these compact solutions prove that environmental responsibility doesn’t require massive infrastructure.

Rebar Thread Rolling Machines in Construction

The construction sector’s shift toward green building standards has propelled demand for rebar thread rolling machines. These specialized systems thread reinforcing bars used in seismic-resistant structures, bridges, and high-rises, replacing welded joints with mechanically locked connections that enhance structural integrity. Environmental benefits are profound:

- Material Conservation: Threaded rebar enables precise cut lengths, eliminating overage waste.

- Emission Reduction: Cold rolling avoids welding fumes and slag byproducts.

- Transport Efficiency: Threaded bars nest compactly, shrinking shipping volumes.

Hebei Moto Machinery’s heavy-duty three-axis models process rebarincorporates automated feeding that minimizes human error and material scrap. Their systems support on-site threading, allowing contractors to customize rebar lengths as needed—dramatically reducing steel waste at construction sites.

FAQs about Eco-Friendly Thread Rolling Tool

How does thread rolling in thread rolling tool compare ecologically to thread cutting?

Thread rolling eliminates coolant usage and metal chips, reducing hazardous waste disposal. Hebei Moto Machinery’s tools further incorporate dry-operating designs, removing lubricant dependency entirely.

Can small thread rolling machines handle high-volume production?

Absolutely. Units like Hebei Moto Machinery’s Yugong series achieve outputs exceeding 50 pieces/minute, rivaling industrial machines while consuming less power per unit.

What makes rebar thread rolling machines vital for sustainable construction?

They enable modular building techniques, where threaded rebar sections are reused across projects. This circular approach slashes steel consumption .

Are eco-friendly thread rolling tools cost-prohibitive?

No. Hebei Moto Machinery’s "high-precision, low-cost" philosophy ensures rapid ROI through energy savings and material conservation—often within 12 months.

How does Hebei Moto Machinery support global sustainability initiatives in thread rolling tool?

With offices in China’s largest fastener hub, they provide localized service to minimize shipping emissions. Their machines are exported globally with carbon-neutral logistics partnerships.

The journey toward sustainable manufacturing isn’t paved with compromises—it’s engineered with innovations like the thread rolling tool. As industries confront ecological challenges, Hebei Moto Machinery Trading Co., Ltd. stands as a beacon of responsible production. Their 28-year legacy, embodied in the Yugong and Baofeiluo brands, demonstrates that environmental stewardship and commercial success are inseparable. From the whisper-quiet small thread rolling machine revitalizing job shops to the titanic rebar thread rolling machine reshaping skylines, every product reflects a commitment to preserving resources without sacrificing precision. In partnering with them, manufacturers don’t just acquire machinery—they join a global movement where efficiency meets ecology, and progress is measured not just in profits, but in planetary impact. Discover how advanced thread rolling can transform your environmental footprint, and become part of the solution today.