-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

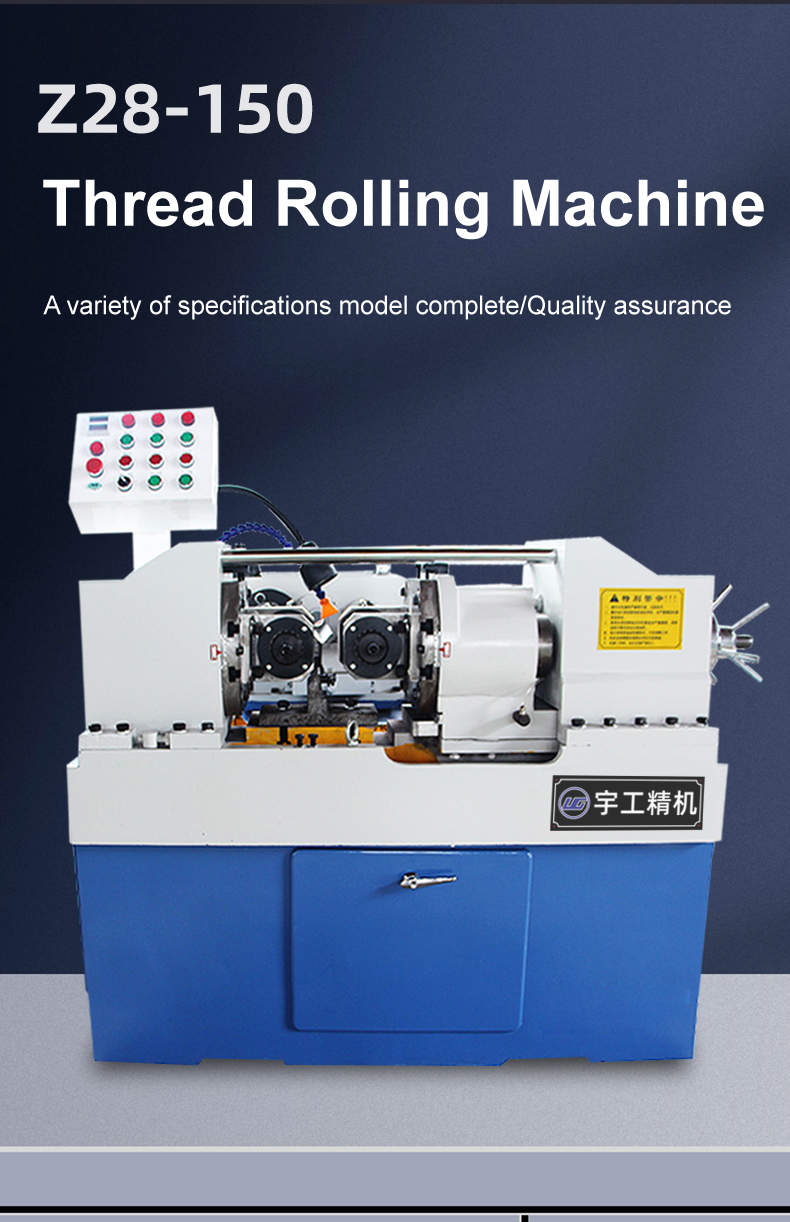

Manufacturers of Roll Threading Machines for Precision Engineering Solutions

The Rise of Roll Thread Machine Factories Innovation in Precision Manufacturing

In the modern manufacturing landscape, the demand for precision-engineered products has surged, propelling the growth of specialized factories, notably those focused on roll thread machines. These machines are essential in various industrial applications, from aerospace and automotive to construction and machinery. Their ability to create strong, reliable threads efficiently makes them indispensable in producing high-quality components.

Roll thread machines operate by deforming material rather than cutting it, a process known as cold rolling. This method not only enhances the mechanical properties of the material but also minimizes waste, resulting in a more sustainable manufacturing process. As industries increasingly prioritize environmental concerns, the efficiency of roll thread machines aligns closely with eco-friendly initiatives, making them a popular choice among manufacturers.

The evolution of technology has significantly impacted roll thread machine factories. Advanced control systems and automation have revolutionized production capabilities. Modern machines are equipped with computerized numerical control (CNC), allowing for precise adjustments and consistency in threading. This technological advancement speeds up production times and reduces labor costs, making factories more competitive in a global market.

roll thread machine factories

Furthermore, the versatility of roll thread machines has expanded their application range. They can produce various thread types, including metric, unified, and custom designs, catering to diverse industrial needs. This adaptability attracts a wide clientele, from large corporations to small-scale businesses.

In addition to machinery, the talent and expertise within roll thread machine factories play a crucial role in their success. Skilled engineers and technicians are essential to operate, maintain, and innovate these machines. Continuous training and development are vital in keeping the workforce abreast of the latest technologies and best practices in manufacturing.

The market for roll thread machines is expected to keep growing, driven by advancements in technology and an ever-increasing demand for precision parts. As industries evolve and new challenges arise, these factories will likely adapt and innovate, incorporating smart manufacturing techniques and Industry 4.0 solutions.

In conclusion, roll thread machine factories represent a significant facet of modern manufacturing. By combining efficiency with precision, sustainability, and adaptability, they are well-positioned to meet the needs of various industries now and in the future. As these factories continue to innovate and expand their capabilities, they will play a critical role in driving the manufacturing sector towards a more efficient and sustainable future.