-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

cnc thread rolling machine service

CNC Thread Rolling Machine Service Enhancing Precision and Efficiency in Thread Production

In the world of manufacturing, precision and efficiency are paramount, especially when it comes to producing threaded components. One of the most effective methods to achieve the desired specifications in threading is through the use of CNC (Computer Numerical Control) thread rolling machines. These sophisticated machines not only enhance productivity but also ensure high-quality results. This article delves into the significance of CNC thread rolling machine services, their advantages, and how they can revolutionize your production processes.

Understanding CNC Thread Rolling Machines

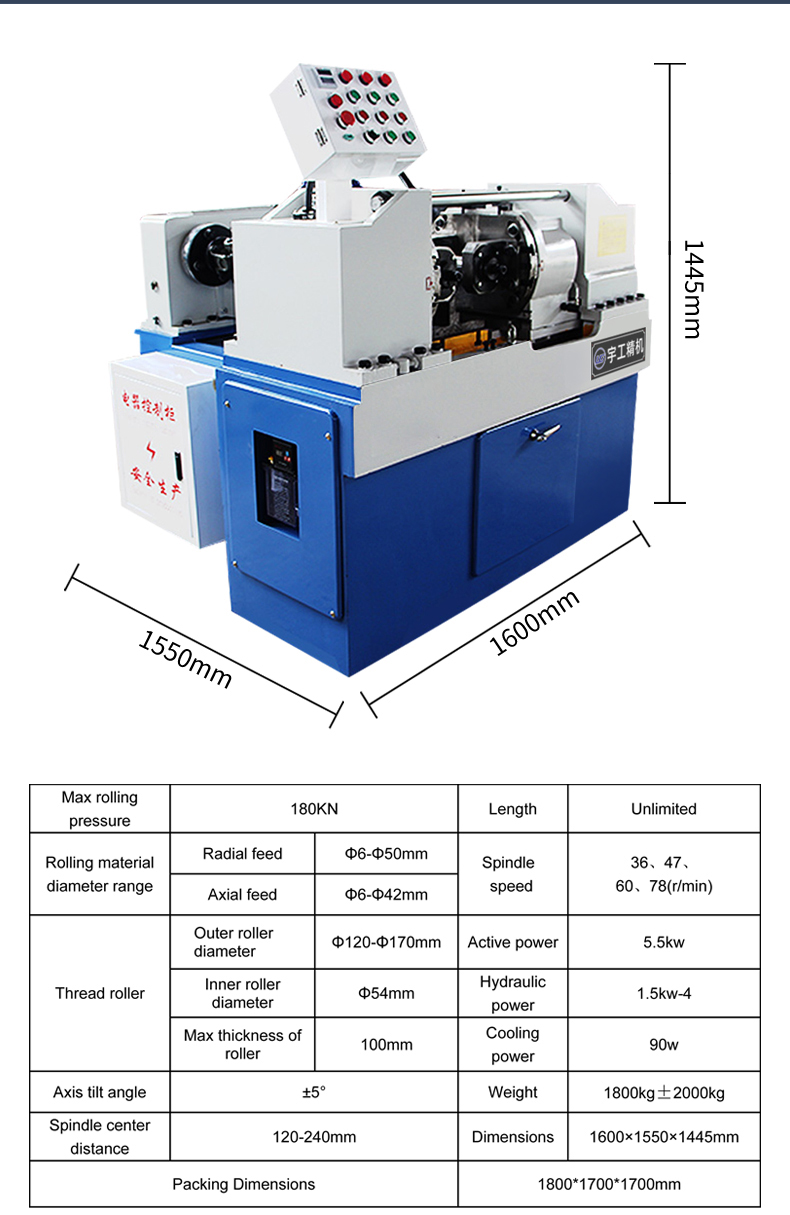

CNC thread rolling machines are specialized equipment designed to create threads on cylindrical workpieces through the process of rolling. Unlike traditional cutting methods, which remove material, thread rolling involves displacing the material to form threads. This process improves the strength of the threads and reduces waste, making it an ideal choice for many industries.

CNC technology allows for precise control over the rolling process, enabling operators to create intricate thread geometries with consistent quality. The machines can be programmed to accommodate various thread specifications, including size, pitch, and profile, making them highly versatile.

Advantages of CNC Thread Rolling Machine Services

1. High Precision and Consistency One of the primary benefits of utilizing CNC thread rolling machines is their ability to produce highly accurate threads. The CNC system ensures that each component meets exact specifications, minimizing the risk of defects and ensuring uniformity across batches.

2. Enhanced Production Speed CNC thread rolling machines operate at high speeds, significantly increasing production efficiency. Continuous and automated operation means that manufacturers can produce large volumes of threaded components in a fraction of the time compared to traditional methods.

3. Material Efficiency The thread rolling process is inherently more material-efficient than cutting threads. Since it displaces rather than removes material, there is less scrap generated, leading to cost savings and reduced environmental impact.

cnc thread rolling machine service

4. Improved Mechanical Properties The cold working involved in thread rolling enhances the mechanical properties of the metal, leading to stronger threads. This strength is crucial for applications where durability and reliability are required, such as in the automotive and aerospace industries.

5. Flexibility and Customization CNC technology allows manufacturers to easily adjust specifications without the need for costly tooling changes. This flexibility makes it feasible to switch between different products and accommodate specific customer requests quickly.

The Role of CNC Thread Rolling Machine Service Providers

While investing in CNC thread rolling machines is beneficial, partnering with a reputable service provider can further enhance the advantages. These service providers offer a range of services, including maintenance, repair, and training, ensuring that the machines operate at peak efficiency.

Regular maintenance is critical to prolonging the life of the equipment and preventing costly downtimes. Service providers can conduct routine checks, calibrate the machines, and replace worn components, helping manufacturers to sustain high productivity levels.

Training services are also vital. Proper training allows operators to maximize the machines' capabilities, ensuring that they can produce quality threads while adhering to safety standards. A knowledgeable workforce is key to achieving operational excellence.

Conclusion

CNC thread rolling machines represent a groundbreaking advancement in threaded component manufacturing. Their ability to produce precise, strong, and consistent threads while enhancing production efficiency makes them a valuable asset in various industries. By utilizing CNC thread rolling machine services, manufacturers can optimize their processes, reduce waste, and ultimately improve their bottom line. As technology continues to evolve, those who adopt these advanced solutions will undoubtedly lead the way in creating high-quality threaded products that meet the demands of modern engineering.