-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

英語

英語 -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Reed Thread Roller Impact on Fabric Selvedge

Achieving a clean, strong, and consistent selvedge (the finished edge of woven fabric) is paramount in textile manufacturing. This edge prevents unraveling, facilitates downstream processing, and directly impacts the fabric's quality and appearance. While weaving involves numerous components, the precision and durability of the reed thread roller, often manufactured using advanced thread rolling machines, play a surprisingly crucial and often underappreciated role. Hebei Moto Machinery Trading Co., Ltd., leveraging its 28 years of expertise in manufacturing high-precision metal processing machinery, understands the intricate connection between robust component manufacturing and end-product quality in diverse industries, including textiles.

Reed Thread Roller :The Critical Link

The selvedge is formed by the interaction of the warp yarns with the loom's reed and the take-up motion.

- The reed thread roller, a component within the reed assembly or related guiding mechanisms, directly contacts the outermost warp yarns. Its primary function is to maintain consistent spacing and tension of these edge yarns during weaving.

- Any imperfection, inconsistency, or premature wear on the surface of this roller can have detrimental effects. Surface roughness can cause excessive friction, leading to yarn abrasion, breakage, and the generation of lint.

- Inconsistent diameter or minor surface defects can create variations in tension across the selvedge yarns, resulting in a wavy, weak, or irregularly formed edge. This is where the manufacturing precision of the roller itself becomes critical.

Hebei Moto Machinery's expertise in producing high-tolerance components using thread rolling machines and other metal forming equipment like nail thread rolling machine variants ensures the rollers possess the necessary surface finish, dimensional accuracy, and geometric consistency to function flawlessly under the demanding conditions of high-speed weaving.

Understanding the Function and Demands on the Reed Thread Roller

- The reed thread rolleroperates under continuous stress. It must withstand the constant friction of yarn sliding across its surface, maintain precise alignment, and resist deformation under tension. Its surface needs to be smooth enough to minimize yarn damage yet possess sufficient grip or geometry to guide the yarns effectively without slippage.

- Furthermore, it must be incredibly durable to maintain its precision over millions of cycles without significant wear that could alter its profile or surface characteristics. Manufacturing such a component requires more than simple turning; it demands processes that enhance surface integrity and material strength.

Cold forming techniques, particularly thread rolling and precision diameter reduction, are ideally suited. These processes displace metal rather than cutting it, creating a smoother, work-hardened surface that is significantly more resistant to wear and fatigue than machined surfaces. This inherent durability translates directly to longer service life for the roller and, consequently, more consistent selvedge formation over extended production runs, reducing downtime for replacements.

Enabling Perfection: The Role of Advanced Thread Rolling Machines

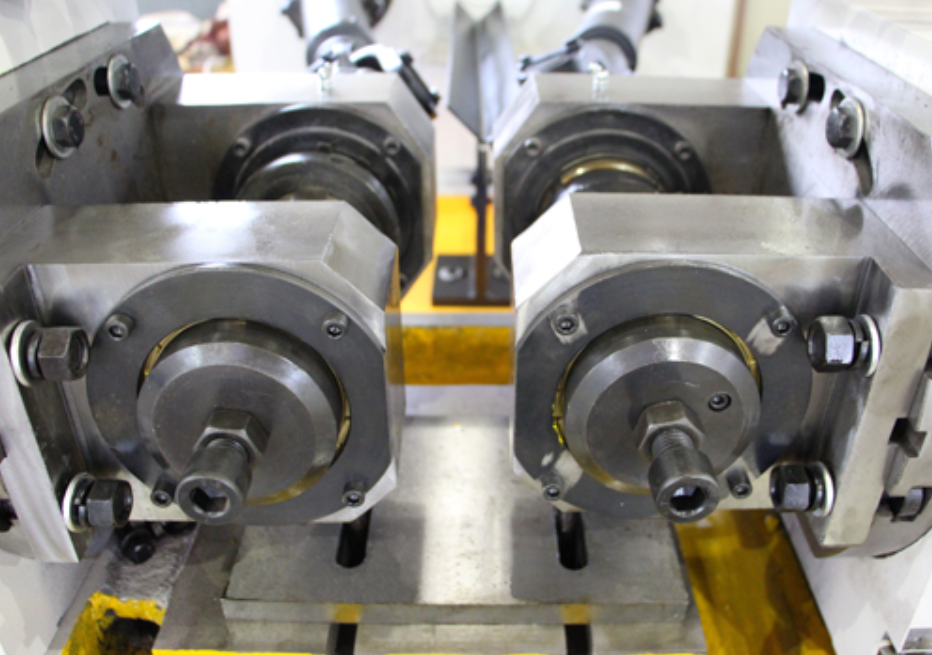

The consistent production of high-quality reed thread roller components hinges on the capabilities of the thread rolling machines used in their manufacture. Hebei Moto Machinery's specialization in two-axis and three-axis thread rolling machines provides the technological backbone. These machines apply immense, controlled pressure to cylindrical blanks, forcing the metal to flow into the precise contours of hardened dies. This creates accurate, strong threads, knurls, or other surface patterns integral to the roller's function. Key advantages for roller production include:

- Superior Surface Finish: Rolling produces a burnished, dense surface that minimizes friction and yarn abrasion.

- Enhanced Strength and Durability:The cold working process increases surface hardness and creates beneficial compressive stresses, drastically improving wear resistance and fatigue life.

- Exceptional Dimensional Accuracy and Consistency: Modern CNC-controlled thread rolling machinesensure every roller produced meets exacting geometric tolerances, batch after batch, which is vital for uniform selvedge quality.

- Material Efficiency:The rolling process is highly efficient, generating minimal waste compared to machining.

Hebei Moto Machinery's comprehensive range, including specialized variants potentially analogous to nail thread rolling machine principles but scaled and configured for industrial roller components, ensures they can meet the specific dimensional and surface pattern requirements of various textile machinery manufacturers. Their commitment to ISO9001 standards guarantees this precision and consistency are maintained throughout large-scale production runs.

FAQs about Nail Thread Rolling Machine

How does wear on a reed thread roller specifically manifest as defects in the fabric selvedge?

Wear typically creates grooves, scratches, or a loss of precise profile on the roller surface. This leads to increased friction, causing broken warp yarns at the edge (leading to "fringes" or unraveling), uneven tension resulting in a wavy, loopy, or tight selvedge, and excessive lint generation. The selvedge may become weak, irregular, or aesthetically unacceptable.

What manufacturing advantage does using a thread rolling machine offer for reed thread rollers compared to machining?

ねじ転造盤 cold-form the metal, creating a smoother, harder, and more wear-resistant surface through work hardening. This significantly extends the roller's lifespan and maintains consistent yarn guidance far longer than a machined surface, which is inherently rougher and more prone to abrasion. Rolling also ensures superior dimensional consistency across large production batches.

Can Hebei Moto Machinery's thread rolling machines produce the specific profiles needed for different reed thread roller designs?

Yes. Hebei Moto Machinery offers a wide range of thread rolling machines, including versatile two-axis and three-axis models, capable of producing a vast array of precise surface patterns – from simple smooth diameters to complex knurls or specialized guiding profiles – required for diverse reed thread roller applications in various loom types. They possess the expertise to configure machines for specific roller geometries.

Why is the durability offered by rolled components like the reed thread roller crucial for large-scale textile production?

Large-scale textile mills operate looms continuously at high speeds. Frequent component failure or degradation leads to costly downtime for replacements and adjustments, wasted material (yarn and fabric), and inconsistent product quality. A highly durable reed thread roller manufactured via rolling minimizes these stoppages, ensures consistent selvedge quality over long production runs, and maximizes overall equipment efficiency.

How does Hebei Moto Machinery support global manufacturers needing reed thread rollers or the machines to make them?

Hebei Moto Machinery, with its extensive inventory and large-scale production capacity, efficiently supplies high-precision thread rolling machines globally. They back this with dedicated after-sales service and technical consultation teams, strategically located near major industrial hubs like China's standard parts base, ensuring prompt support for manufacturers producing critical components like reed thread roller assemblies anywhere in the world. Their commitment is to be a reliable long-term partner.

The quality of the fabric selvedge is inextricably linked to the precision and durability of the components that guide and form it. The reed thread roller, though a seemingly small part, has a significant impact. Its consistent performance relies heavily on advanced manufacturing techniques, particularly the use of precision thread rolling machines. Hebei Moto Machinery Trading Co., Ltd. focus on high-precision, durable production through technologies like thread rolling ensures that components such as the reed thread roller meet the rigorous demands of modern textile manufacturing, contributing directly to the production of flawless fabric. By prioritizing innovation, quality, and partnership, as reflected in their commitment to customer collaboration for mutual development, Hebei Moto Machinery supports industries worldwide in achieving their manufacturing excellence goals.