-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Efficient Precision Nail Thread Rolling Machines for High-Quality Production and Durability

High-Quality Nail Thread Rolling Machine A Game Changer in Manufacturing

In the realm of manufacturing, precision and efficiency are paramount. This is especially true in industries where fasteners, like nails, play a crucial role. The introduction of the high-quality nail thread rolling machine has revolutionized the production of threaded nails, ensuring that they meet the highest standards of durability and performance. This article delves into the features and advantages of these machines, illustrating why they are essential for modern manufacturing processes.

High-Quality Nail Thread Rolling Machine A Game Changer in Manufacturing

One of the standout features of a high-quality nail thread rolling machine is its ability to produce a large volume of nails in a short period. Advanced machines can roll threads at a remarkable speed, significantly increasing productivity while maintaining tight tolerances. For manufacturers, this efficiency translates into reduced labor costs and accelerated time-to-market for their products. As a result, businesses can respond more swiftly to market demands without sacrificing quality.

high quality nail thread rolling machine

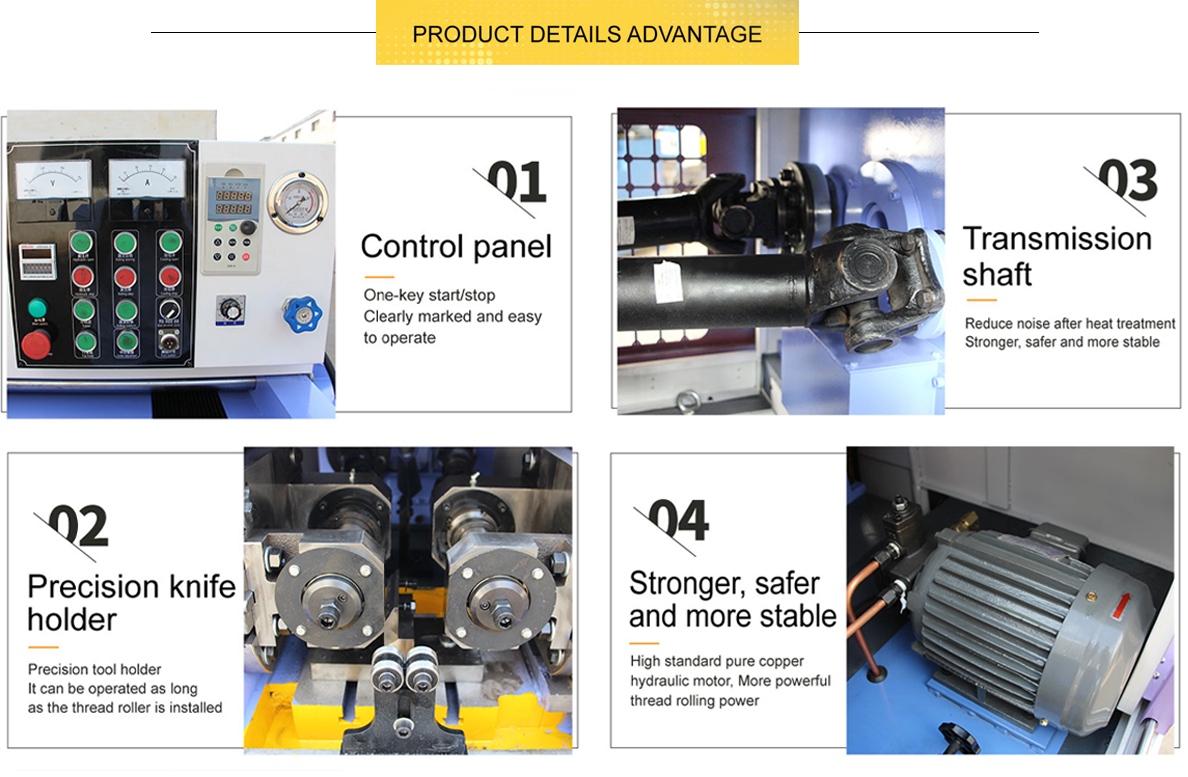

Moreover, these machines incorporate the latest technology, which enhances their performance and reliability. Many of them are equipped with programmable automation systems that allow for easy adjustments based on the specifications of different nail sizes and thread types. This flexibility is crucial for manufacturers who need to produce varying products to meet diverse customer needs. Additionally, modern machines often feature integrated inspection systems that continuously monitor the quality of the threaded nails, ensuring that any defects are caught and rectified immediately. This level of quality control is vital in maintaining the reputation of any manufacturing brand.

Sustainability is another aspect where high-quality nail thread rolling machines excel. The rolling process generates significantly less waste compared to traditional cutting methods. Since material is not being removed, manufacturers can maximize their raw material usage, contributing to more sustainable production practices. This is an increasingly important consideration in today’s environmentally conscious market, where consumers and businesses alike are looking for greener alternatives.

Furthermore, the durability of nails produced through thread rolling adds value to the final product. Rolled threads perform better under stress and are less likely to strip or deform during use. This characteristic is particularly advantageous in construction and heavy-duty applications, where the integrity of fasteners is paramount. As a result, end-users can trust that the nails they are using will perform reliably, thereby enhancing overall safety and structural integrity.

In conclusion, the high-quality nail thread rolling machine stands out as an indispensable asset in the manufacturing industry. Its ability to produce precise, durable, and sustainable threaded nails meets the demands of modern production while ensuring efficiency and quality. Manufacturers looking to stay competitive must consider investing in these advanced machines, as they not only enhance productivity but also contribute to higher customer satisfaction through superior product quality. With the continued evolution of technology, the future of nail manufacturing looks brighter than ever, making high-quality nail thread rolling machines a key player in this dynamic landscape.