-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

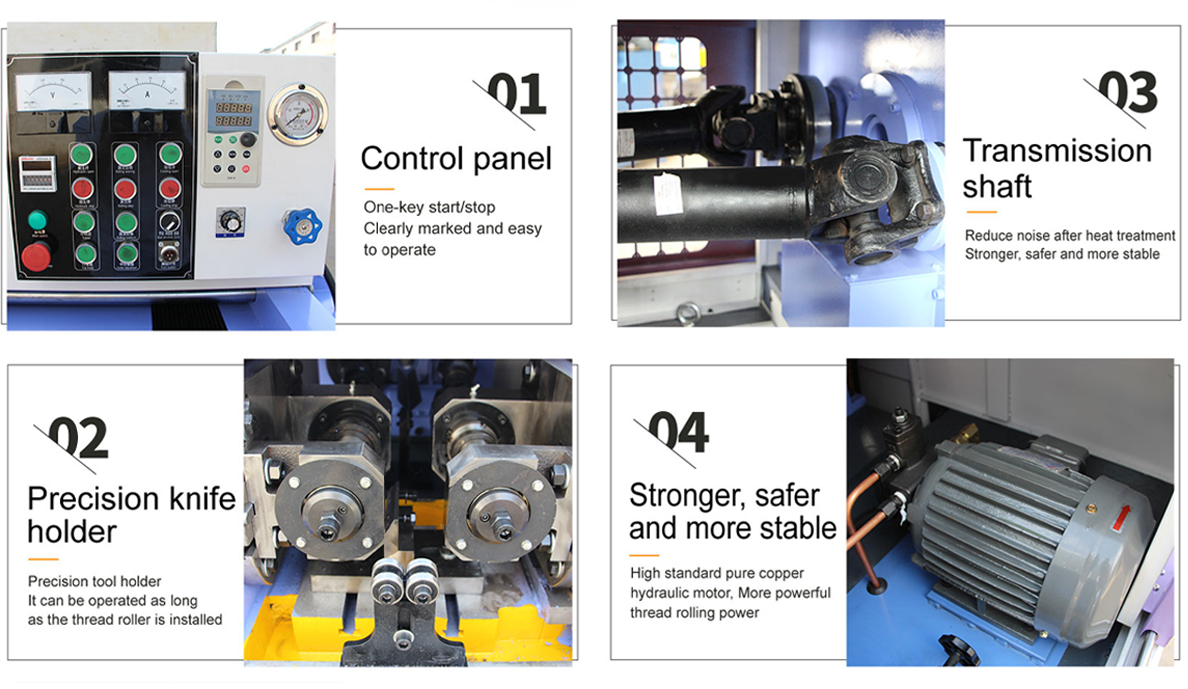

High-Quality Thread Rolling Machines for Efficient 3 Die Production

The Advantages of 3% Die Thread Rolling Machines in the Manufacturing Sector

In the world of manufacturing, the demand for precision and efficiency is ever-increasing. One of the critical processes that significantly contribute to these demands is thread rolling, particularly with machines that utilize a die rolling system. Among the various options available, 3% die thread rolling machines have emerged as notable choices for companies seeking to enhance their production capabilities. This article delves into the features, advantages, and applications of 3% die thread rolling machines.

What is a 3% Die Thread Rolling Machine?

A 3% die thread rolling machine is designed to create threads on metal rods and components efficiently. The term 3% die refers to the specific configuration of the dies used in the machine, which allows for precise shaping of the threads. Unlike traditional cutting methods, die rolling forms threads by displacing the material rather than removing it. This process not only improves the durability of the threads but also enhances the overall efficiency of production.

Key Advantages

1. Increased Strength and Durability

One of the primary benefits of using a 3% die thread rolling machine is the enhanced strength of the finished threads. The cold working process involved in thread rolling aligns the grain structure of the metal, leading to improved tensile strength. This characteristic is vital in applications where components must withstand high stress and wear, such as in the automotive and aerospace industries.

2. Superior Surface Finish

Thread rolling produces a finer surface finish compared to conventional cutting methods. The displacement of material creates smoother threads, reducing the chances of stress concentration points that can lead to failure. This excellent surface quality is particularly advantageous for components requiring tight tolerances and those subjected to corrosive environments.

3. Higher Material Utilization

3 die thread rolling machine products

Traditional machining processes often result in significant material wastage due to cutting and shaping. Conversely, thread rolling minimizes material loss, with studies indicating that it utilizes up to 98% of the original material. This efficiency is a crucial consideration for manufacturers focused on sustainability and cost-effectiveness, allowing for lower raw material costs and reduced waste.

4. Increased Production Efficiency

3% die thread rolling machines are capable of producing threads at a much faster rate than machining processes. The rapid production speeds enable manufacturers to meet high-volume demand without sacrificing quality. Additionally, the automation capabilities of modern rolling machines further enhance efficiency, reducing labor costs and minimizing the risk of human error.

5. Versatility

Another advantage of these machines is their versatility. They can work with a wide variety of materials, including aluminum, steel, and even softer metals, making them suitable for numerous applications across various industries. From creating bolts and screws to manufacturing specialized fasteners, 3% die thread rolling machines can meet diverse production needs.

Applications in Various Industries

The applications of 3% die thread rolling machines are extensive. In the automotive industry, they are used to produce components like wheel bolts and engine parts that require high strength and durability. The aerospace sector benefits from the lightweight yet strong components made possible by thread rolling. Similarly, in the construction industry, these machines produce secure and reliable fasteners critical for structural integrity.

Conclusion

The adoption of 3% die thread rolling machines is revolutionizing manufacturing processes across various sectors. With their ability to produce durable, high-quality threads efficiently and with minimal waste, these machines offer significant advantages over traditional methods. As the industry continues to prioritize efficiency and sustainability, the use of 3% die thread rolling machines represents a forward-thinking solution that meets the demands of modern manufacturing. Investing in this technology not only enhances production capabilities but also supports a more sustainable approach to manufacturing, making it a worthwhile consideration for manufacturers worldwide.