-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

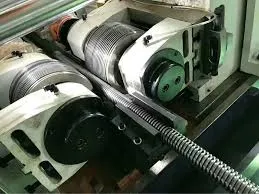

Production of Precision Machinery for Thread Rolling Applications in Industry

The Future of Thread Rolling Equipment Manufacturing

Thread rolling equipment plays a pivotal role in the manufacturing of fasteners and precision components used in various industries, ranging from automotive to aerospace. As the demand for high-quality, durable threaded parts continues to rise, the thread rolling equipment factory becomes a significant hub of innovation and productivity. This article explores the importance of thread rolling technology, the advancements in equipment manufacturing, and the future prospects of this industry.

Understanding Thread Rolling Technology

Thread rolling is a cold-forming process that creates threads on cylindrical parts, such as bolts, screws, and nuts. Unlike traditional cutting methods, which remove material, thread rolling reshapes the metal, ensuring that the resulting threads are robust and precise. The process increases the tensile strength of the material, minimizes waste, and often reduces production costs. As industries evolve and prioritize efficiency, the role of thread rolling equipment becomes increasingly crucial.

Advances in Thread Rolling Equipment

In recent years, thread rolling equipment manufacturers have embraced technological advancements to enhance production capabilities. Automation and robotics have transformed the landscape, allowing for higher volumes of production with increased precision. Modern machines are equipped with advanced CNC (Computer Numerical Control) systems, which enable manufacturers to achieve tighter tolerances and repeatable quality in their products.

Additionally, the integration of Industry 4.0 concepts, such as IoT (Internet of Things) integration and real-time data analytics, offers factories unprecedented insights into their operations. By monitoring machine performance and production metrics, manufacturers can identify areas for improvement, optimize resource allocation, and reduce downtime.

Sustainability has also become a focal point in thread rolling equipment manufacturing. Companies are now exploring eco-friendly practices, including energy-efficient machinery and waste-reduction strategies. These innovations not only minimize the environmental impact but can also lead to long-term cost savings and enhanced brand reputation.

The Importance of Skilled Workforce

thread rolling equipment factory

Despite the rise of automation, a skilled workforce remains vital to the success of thread rolling equipment factories. Experienced operators and engineers are essential for managing complex machinery, troubleshooting issues, and ensuring quality control. As technology evolves, there is an increasing need for training programs that equip workers with the necessary skills to operate modern equipment.

Collaboration between manufacturers, educational institutions, and industry associations has become critical in developing training curricula that meet the evolving demands of the industry. By fostering a skilled workforce, thread rolling equipment factories can ensure they remain at the forefront of innovation and competitiveness.

Industry Applications and Market Demand

The applications of thread rolling technology are vast, spanning industries such as automotive, aerospace, electronics, and construction. As these sectors grow, so too does the demand for high-quality threaded components. The automotive industry, for instance, increasingly relies on lightweight materials and innovative designs, prompting the need for advanced thread rolling solutions that support these requirements.

Furthermore, the trend toward custom and small-batch production has necessitated flexible and adaptable manufacturing processes. Thread rolling equipment that can handle a variety of materials and thread specifications will be crucial in meeting the diverse needs of modern manufacturers.

Future Prospects

Looking ahead, the future of thread rolling equipment factories appears promising. With continuous advancements in technology, there are immense opportunities for growth and development. The increasing focus on automation, sustainability, and workforce training will empower manufacturers to meet the evolving needs of the market.

As global supply chains stabilize and industries recover from recent disruptions, the thread rolling equipment market is expected to expand. Manufacturers that invest in innovative technologies and skilled labor will be well-positioned to thrive in this competitive landscape.

In conclusion, thread rolling equipment factories are integral to the production of high-quality threaded components across various sectors. By leveraging technological advancements, prioritizing sustainability, and nurturing a skilled workforce, these manufacturers can unlock new opportunities and drive the future of precision engineering. As the industry evolves, thread rolling technology will continue to be a cornerstone of modern manufacturing, propelling innovation and efficiency forward.