-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

flat die thread rolling machine factories

The Role of Flat Die Thread Rolling Machines in Manufacturing

In the modern manufacturing landscape, precision, efficiency, and quality are paramount. Among the essential equipment that fulfills these requirements is the flat die thread rolling machine. This machine plays a crucial role in creating high-quality threaded components for various industries, including automotive, aerospace, and mechanical manufacturing.

Understanding Flat Die Thread Rolling Machines

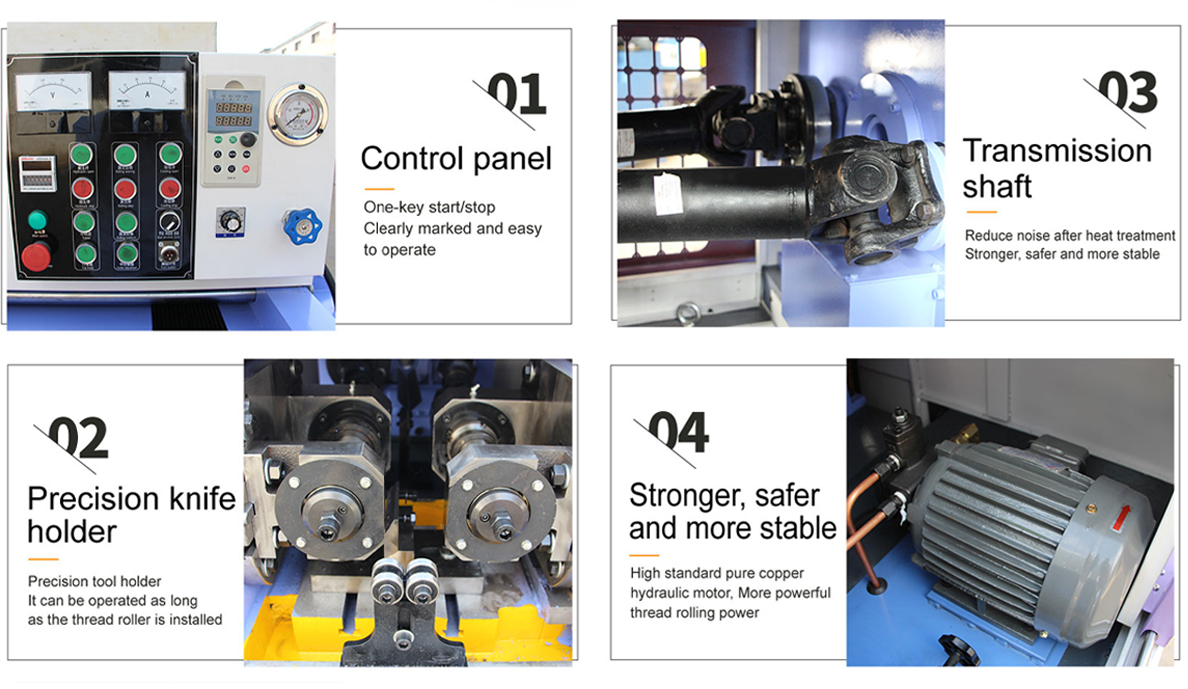

Flat die thread rolling machines use the process of cold forming to create threads on metal components. Unlike traditional cutting methods that remove material to form threads, rolling machines deform the material to create threads, which enhances the mechanical properties of the metal and retains its integrity. The flat die design allows the machine to produce multiple threads simultaneously, providing a higher throughput and reducing production time.

The basic working principle involves placing a metal rod or blank between two flat dies that have the desired thread profile. As the dies come together and rotate, they compress the material, creating the threads through sheer force. This process can be applied to various metals, including aluminum, steel, and brass, making it versatile for different applications.

Advantages of Using Flat Die Thread Rolling Machines

One of the significant advantages of flat die thread rolling machines is their efficiency. The cold forming process requires less energy compared to traditional machining methods, leading to lower operational costs. Additionally, the absence of cutting tools means reduced tool wear, which translates to lower maintenance costs and less downtime.

Another key benefit is the superior quality of the threads produced

. Since thread rolling compresses the material, it often results in stronger and more durable threads with improved fatigue resistance. This characteristic is particularly vital in industries where components are subjected to high stresses, such as in automotive or aerospace applications.Furthermore, the flat die design allows for the production of various thread sizes and types, which can be tailored according to specific industry needs. The ability to adapt to different production demands makes flat die thread rolling machines an attractive option for manufacturers looking to enhance their offering or respond swiftly to market changes.

flat die thread rolling machine factories

Applications Across Industries

Flat die thread rolling machines have extensive applications across different sectors. In the automotive industry, they are commonly used to manufacture components like bolts, screws, and fasteners that require precision threads for secure assemblies. In aerospace, where safety and reliability are paramount, the use of high-quality rolled threads ensures that components can withstand the stress of flight conditions.

Moreover, the machinery is also prevalent in the manufacturing of construction equipment, electrical appliances, and even in the production of medical devices. The versatility of the flat die thread rolling machine enables it to address the threading needs of a wide range of applications, making it an invaluable asset in any manufacturing setup.

The Future of Flat Die Thread Rolling Machines

As technology continues to advance, flat die thread rolling machines are evolving to meet the changing needs of the industry. Modern machines are increasingly equipped with automation features that enhance precision and ease of use. With the integration of computer numerical control (CNC) systems, manufacturers can achieve a higher level of accuracy and consistency in their production processes.

In addition, the trend towards sustainability in manufacturing is leading to innovations focused on reducing waste and energy consumption. Flat die thread rolling machines, due to their efficient material use and lower energy requirements, align well with environmentally friendly manufacturing practices.

Conclusion

In conclusion, flat die thread rolling machines are a cornerstone of modern manufacturing, offering a blend of efficiency, quality, and versatility. Their ability to produce durable threads makes them indispensable in various industries, from automotive to aerospace. As the manufacturing landscape continues to evolve, these machines will undoubtedly play a vital role in shaping the future of precision threading, contributing to the ongoing quest for excellence in production. Embracing the advancements in this technology will allow manufacturers to remain competitive and meet the ever-increasing demands of the market.