-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Efficient Mini Thread Rolling Machine Maintenance and Support Solutions

The Significance of Mini Thread Rolling Machine Services in Modern Manufacturing

In today’s fast-paced manufacturing environment, companies are constantly seeking efficient ways to enhance their production lines. Among these innovations, the mini thread rolling machine has emerged as a crucial tool for producing high-quality threaded components with precision and speed. As industries strive to streamline their operations and reduce costs, the service and maintenance of these machines play a vital role in ensuring optimal performance and longevity.

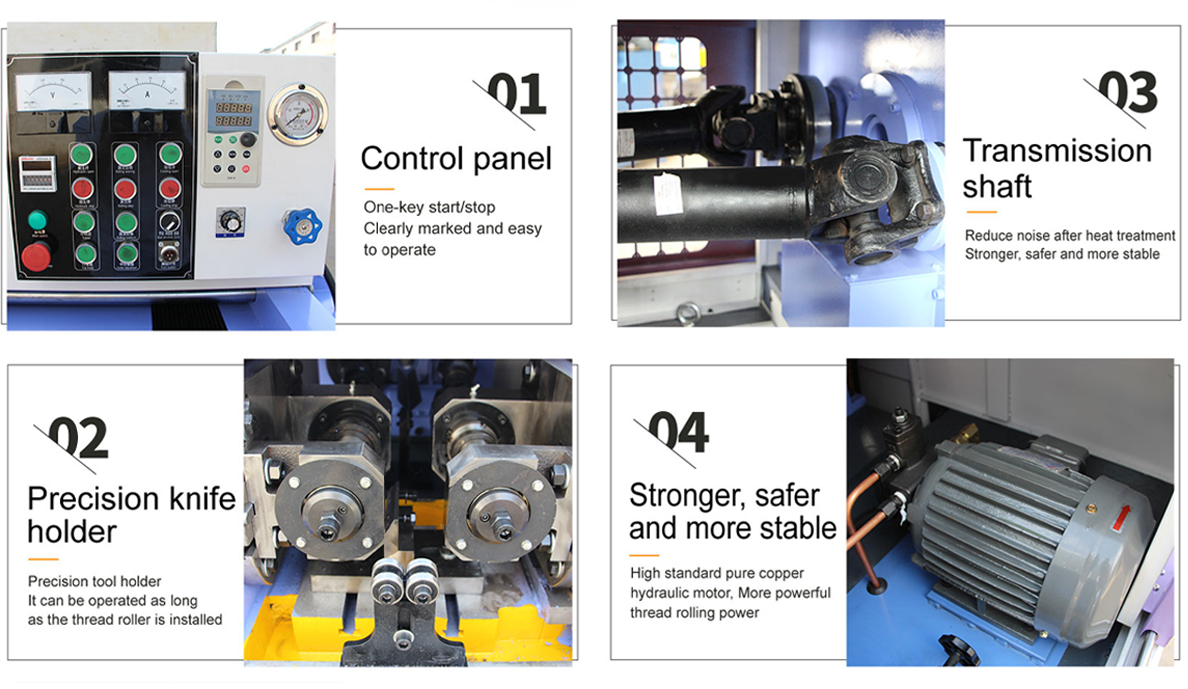

Understanding Mini Thread Rolling Machines

Mini thread rolling machines are compact, specialized devices designed for creating external threads on metal parts through a cold forming process. Unlike traditional cutting methods, which remove material, thread rolling reshapes the material without generating chips. This method not only conserves material but also enhances the mechanical properties of the threads produced, resulting in stronger and more durable components. These machines are ideal for small to medium-sized production runs, making them a popular choice among various industries, including automotive, aerospace, and electronics.

Advantages of Thread Rolling

The benefits of using mini thread rolling machines are manifold. First and foremost, they deliver a high level of precision in thread specifications, which is essential for applications requiring tight tolerances. Additionally, the cold working process improves the material's tensile strength and fatigue resistance, resulting in a superior final product. The efficiency of these machines allows for faster production times, which directly impacts a company’s bottom line by reducing labor and operational costs.

The Importance of Proper Service

mini thread rolling machine service

To maximize the benefits of mini thread rolling machines, regular maintenance and servicing are imperative. Over time, even the most advanced machines can experience wear and tear that affects their performance. Routine inspections help identify potential issues before they escalate into costly breakdowns. Services may include cleaning and lubrication of critical components, calibration to ensure consistent thread quality, and replacement of worn-out parts.

Moreover, trained technicians can provide insights into best practices for operating the machines efficiently. They can assist in optimizing production parameters, which can lead to improved cycle times and reduced scrap rates. A well-maintained machine not only enhances productivity but also ensures the safety of operators, as malfunctioning equipment can pose significant risks.

Choosing the Right Service Provider

When it comes to servicing mini thread rolling machines, choosing the right service provider is crucial. Companies should look for firms that specialize in thread rolling technology and have a proven track record of excellence in machine maintenance. It’s beneficial to select a provider that offers comprehensive services, including on-site support, emergency repairs, and training for production staff.

Furthermore, a reputable service provider will stay updated with the latest advancements in thread rolling technology, ensuring that their clients are equipped with the most efficient and effective solutions. Establishing a long-term relationship with a service provider can lead to ongoing support and tailored solutions that align with a company’s specific manufacturing needs.

Conclusion

In conclusion, the mini thread rolling machine is a vital component in modern manufacturing, offering precision, efficiency, and strength in threaded products. However, to fully realize its potential, regular maintenance and servicing are necessary. By investing in these services, companies can sustain productivity, enhance product quality, and secure a competitive edge in their respective markets. As industries continue to evolve, the role of thread rolling technology and its associated services will remain critical to achieving manufacturing excellence.