-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine pricelist

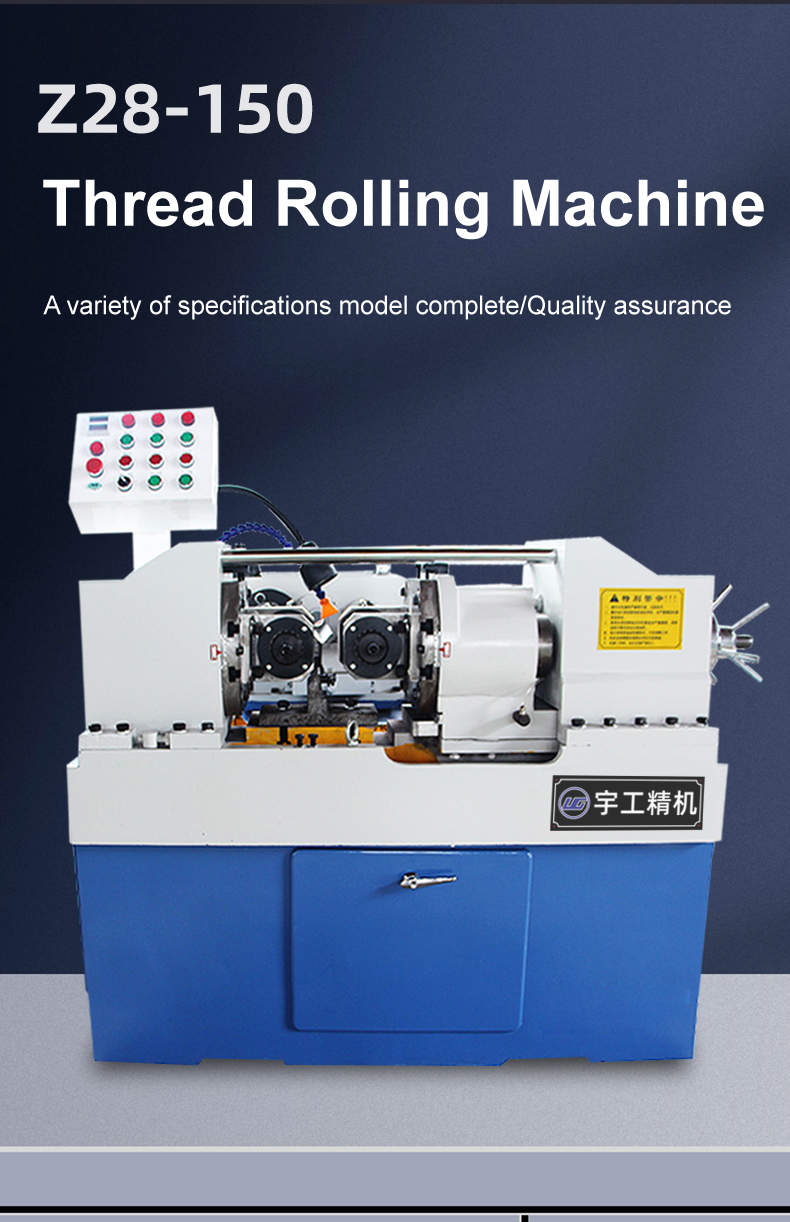

Understanding the Pricing of Thread Rolling Machines

Thread rolling machines are essential tools in various industries for producing consistent and high-quality threads on metal components. These machines use a process that forms threads by displacing material rather than removing it, which enhances the strength and integrity of the final product. As the demand for precision-engineered components grows, understanding the pricing of thread rolling machines becomes crucial for manufacturers and businesses alike.

The prices of thread rolling machines can vary widely depending on several factors, including the machine's design, size, capabilities, and the manufacturer. Generally, entry-level machines suitable for smaller operations or less demanding applications start at around $10,000. These machines typically have a lower capacity and may be limited in features but are adequate for basic needs.

On the higher end of the spectrum, advanced thread rolling machines equipped with automation features, such as CNC (Computer Numerical Control) capabilities, can exceed $100,000. These machines offer greater precision, speed, and flexibility, making them ideal for high-volume production environments. The ability to program complex threading patterns and adjust settings electronically enhances efficiency and reduces labor costs in the long run.

thread rolling machine pricelist

Additional factors that influence pricing include the machine's construction quality, the materials used, and the technology involved in its operation. High-quality machines are often built with durable materials that withstand the rigors of industrial use, justifying a higher price point. Similarly, machines that incorporate advanced technologies, like servo motors for improved control and energy efficiency, may also come at a premium.

Moreover, the size and capacity of the thread rolling machine greatly impact its price. Large machines capable of rolling threads on bigger or more extensive workpieces will naturally cost more than smaller, less capable models. Manufacturers need to assess their specific production needs and choose a machine that aligns with their operational goals while staying within budget.

Finally, it’s essential for businesses to consider the total cost of ownership when evaluating thread rolling machines. This includes maintenance costs, the availability of spare parts, and the potential for upgrades. Investing in a more expensive machine that offers lower operational costs and increased productivity can yield significant long-term savings.

In conclusion, understanding the various factors that contribute to the pricing of thread rolling machines is vital for companies looking to invest in such equipment. By considering their specific requirements and the overall value of the machinery, businesses can make informed decisions that enhance their production capabilities while remaining cost-effective.