-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

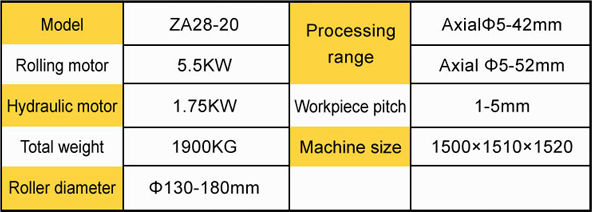

Scaffolding Pipe Thread Rolling Machine Manufacturer and Supplier Solutions

The Importance of Scaffolding Pipe Thread Rolling Machine Companies in the Construction Industry

In the ever-evolving construction industry, efficiency and safety are paramount. One of the crucial components that facilitate both is the scaffolding system, and within this realm, scaffolding pipe thread rolling machines play a significant role. These machines are essential for creating durable, high-quality threaded pipes that serve many structural purposes in construction projects. Companies specializing in these machines are pivotal to ensuring that construction operations are safe, efficient, and cost-effective.

Understanding Scaffolding and Its Importance

Scaffolding provides temporary support and access to various construction areas, ensuring workers can perform their tasks safely and effectively at height. It consists of a network of pipes and boards that must be both strong and reliable. The integrity of this scaffolding largely depends on the quality of the pipes used, which is why the manufacturing process, including threading, is critical.

The Role of Thread Rolling Machines

Scaffolding pipe thread rolling machines are specialized equipment designed to create threads on pipes. The thread is crucial for joining different scaffold components securely. The rolling process generates robust threads that enhance the connection strength, thus increasing the overall safety of the scaffolding system. Unlike traditional cutting methods, thread rolling is a cold-forming process, which means there is no material loss, and the structural integrity of the pipe is maintained.

These machines operate by feeding pipes through a set of rollers that shape the threads without removing any material. This process not only ensures a consistent and precise fit but also enhances the tensile strength of the pipe due to the work hardening that occurs during rolling. Consequently, companies that manufacture scaffolding pipe thread rolling machines contribute to the production of stronger, more durable scaffolding systems.

Regulatory Compliance and Engineering Innovations

scaffolding pipe thread rolling machine company

In the construction industry, meeting safety regulations is non-negotiable. Scaffolding components must comply with various standards to ensure they can withstand the demands of construction work. Companies that produce scaffolding pipe thread rolling machines are continuously innovating to meet these standards. They invest in research and development to improve their machinery's precision and efficiency while adhering to the latest safety regulations.

Modern thread rolling machines incorporate advanced technology such as CNC (Computer Numerical Control) systems, which enhance accuracy and minimize human error. Such innovations not only streamline the manufacturing process but also allow for more complex threading designs that can improve the versatility of scaffolding systems.

Market Demand and Sustainability

The demand for scaffolding in the construction industry continues to grow as urbanization expands and infrastructure projects increase worldwide. This uptick in demand directly influences companies that focus on manufacturing scaffolding pipe thread rolling machines. As construction companies strive for sustainability, manufacturers are also exploring greener technologies and practices, such as energy-efficient machines and recyclable materials, to minimize their environmental impact.

Additionally, the growth of modular construction techniques, which require offsite fabrication and assembly, further drives the need for high-quality scaffolding components, reinforcing the importance of reliable thread rolling technology.

Conclusion

The companies that design and produce scaffolding pipe thread rolling machines play a critical role in the construction industry. By ensuring the quality and strength of scaffolding components, they contribute to safer working environments and more efficient construction processes. As the industry continues to evolve, these manufacturers will remain at the forefront, pushing the boundaries of technology and innovation, while also addressing the crucial needs for safety and sustainability in construction. The advancement of scaffolding pipe thread rolling machines is not just about manufacturing; it reflects the commitment to building a safer, more efficient, and sustainable future in construction.