-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread roller machine factories

Exploring the World of Thread Roller Machine Factories

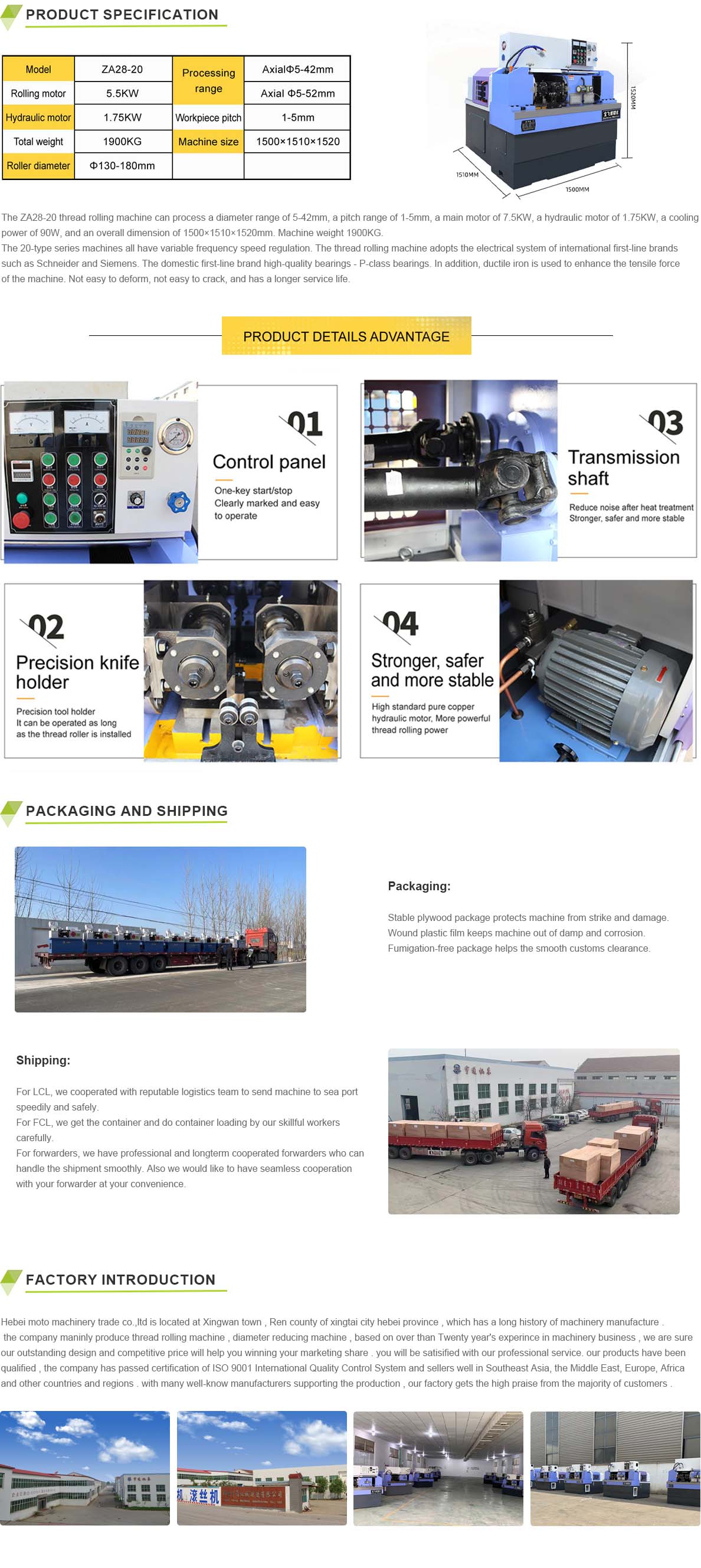

Thread roller machines are essential in the manufacturing sector, primarily focusing on producing threaded fasteners such as screws, bolts, and nuts. The factories specializing in these machines play a crucial role in optimizing production efficiency and quality. In recent years, the demand for high-quality threaded products has skyrocketed due to the rapid expansion of various industries including automotive, aerospace, and construction. This article delves into the significance of thread roller machine factories, their operations, and advancements in technology.

Thread rolling is a cold-forming process that enhances the durability and strength of fasteners compared to traditional machining methods. Thread roller machines utilize a process where a blank piece of metal is shaped into a threaded component through the application of high pressure. This process minimizes material waste and enhances production efficiency by allowing manufacturers to produce large volumes of products in a shorter amount of time.

Factories that specialize in thread roller machines are often equipped with state-of-the-art technology and skilled workforce. These facilities typically house various types of machinery tailored for specific applications, including both automatic and semi-automatic roller machines. As industries evolve, so do the machines, with increasing automation leading to improved output and reduced labor costs.

thread roller machine factories

Moreover, sustainability is becoming an essential focus in thread rolling machine factories. Companies are increasingly adopting eco-friendly practices by recycling materials and implementing energy-efficient technologies. This shift not only aligns with global sustainability goals but also meets the growing consumer demand for environmentally responsible products.

Innovation is at the heart of these factories, with ongoing research and development efforts aimed at improving machinery design and functionality. The integration of computer numerical control (CNC) technology has revolutionized the production process, allowing for precision engineering and increased customization. Factories are now capable of producing intricate designs and meeting stringent quality standards that many industries require.

In conclusion, thread roller machine factories represent a critical component of the manufacturing landscape. Their ability to produce high-quality threaded fasteners efficiently and sustainably positions them as vital players in the supply chain of numerous industries. As technology continues to advance, these factories will likely enhance their capabilities, driving forward the production of essential components that keep various sectors running smoothly. The future of thread rolling is promising, with innovation and sustainability taking center stage in this evolving industry.