-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

oem thread rolling machine video

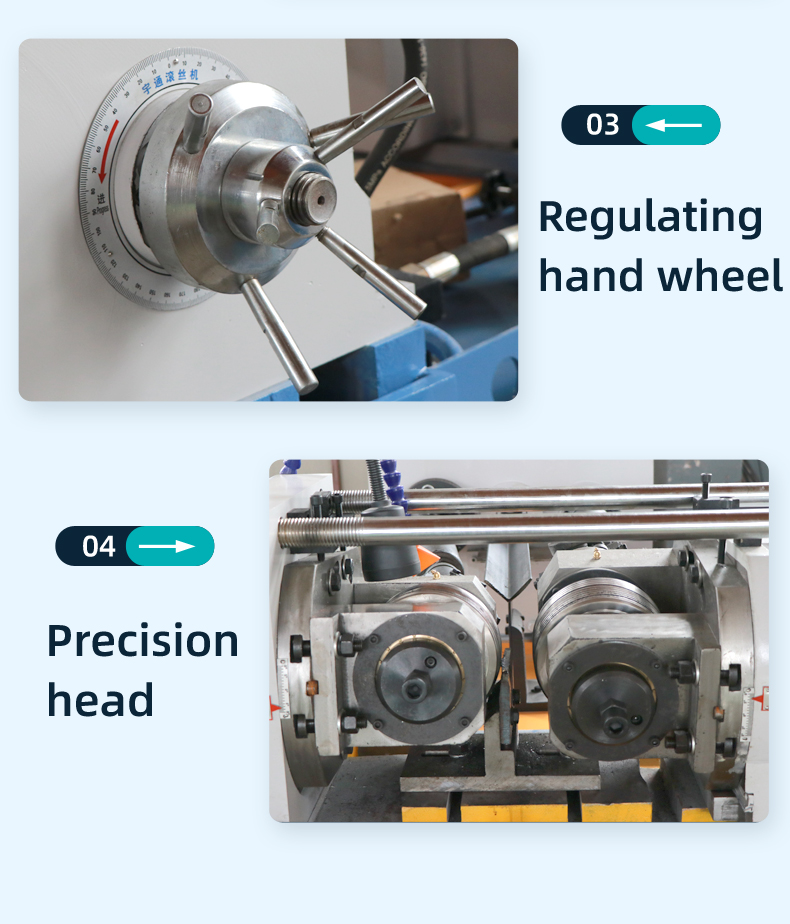

The World of OEM Thread Rolling Machines A Closer Look

In the manufacturing industry, the precision and quality of threaded components are paramount. Among various methods of creating threads, thread rolling has emerged as a significant technique, particularly with the advent of OEM (Original Equipment Manufacturer) thread rolling machines. These machines are designed to produce superior threaded parts efficiently and cost-effectively, gaining popularity across multiple sectors.

What is Thread Rolling?

Thread rolling is a cold forming process that involves deforming the material into the desired thread shape using dies. Unlike traditional machining methods, which remove material to create threads, thread rolling compresses the material, resulting in a denser and stronger final product. This method not only improves the mechanical properties of the threads but also enhances surface finish, reducing the need for additional processing.

The Role of OEM Thread Rolling Machines

OEM thread rolling machines are specifically designed for high-volume production, offering manufacturers the ability to streamline their production process. These machines are tailored to meet the unique requirements of different industries, such as automotive, aerospace, and electronics. The flexibility and adaptability of OEM machines allow manufacturers to produce a variety of thread sizes and configurations without significant downtime or reconfiguration.

Advantages of Using OEM Thread Rolling Machines

1. Increased Production Efficiency Because thread rolling machines can produce threads faster than traditional methods, manufacturers can significantly increase their output. This efficiency translates to lower production costs and quicker turnaround times.

oem thread rolling machine video

2. Enhanced Thread Integrity The cold forming process used in thread rolling ensures that threads are not only precise but also possess higher tensile strength. The grains of the material are compressed, resulting in less brittleness and greater durability.

3. Lower Waste Generation Since thread rolling does not remove material, it produces less waste compared to machining methods. This not only saves material costs but is also more environmentally friendly.

4. Versatility OEM machines can be designed to handle various materials, including steel, aluminum, and plastic. This versatility makes them suitable for a wide range of applications.

5. Cost-Effectiveness While the initial investment in OEM thread rolling machines can be significant, the long-term savings associated with their efficiency and reduced waste make them cost-effective in the long run.

The Future of Thread Rolling Technology

As technology continues to evolve, so does the design and capability of thread rolling machines. Innovations such as automation, advanced computer controls, and integration with Industry 4.0 principles are shaping the future of manufacturing. These advancements will not only improve operational efficiency but also enhance the precision and quality of threaded components.

In conclusion, OEM thread rolling machines are revolutionizing the way manufacturers produce threaded components. Their efficiency, versatility, and cost-effectiveness make them an invaluable asset in various industries. As we look to the future, the ongoing technological advancements promise to drive further improvements in the thread rolling process, ensuring that it remains a vital technique in the world of manufacturing.

Whether you are a manufacturer looking to upgrade your production capabilities or simply curious about industrial processes, exploring the realm of OEM thread rolling machines is both fascinating and essential in today's fast-paced market.