-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

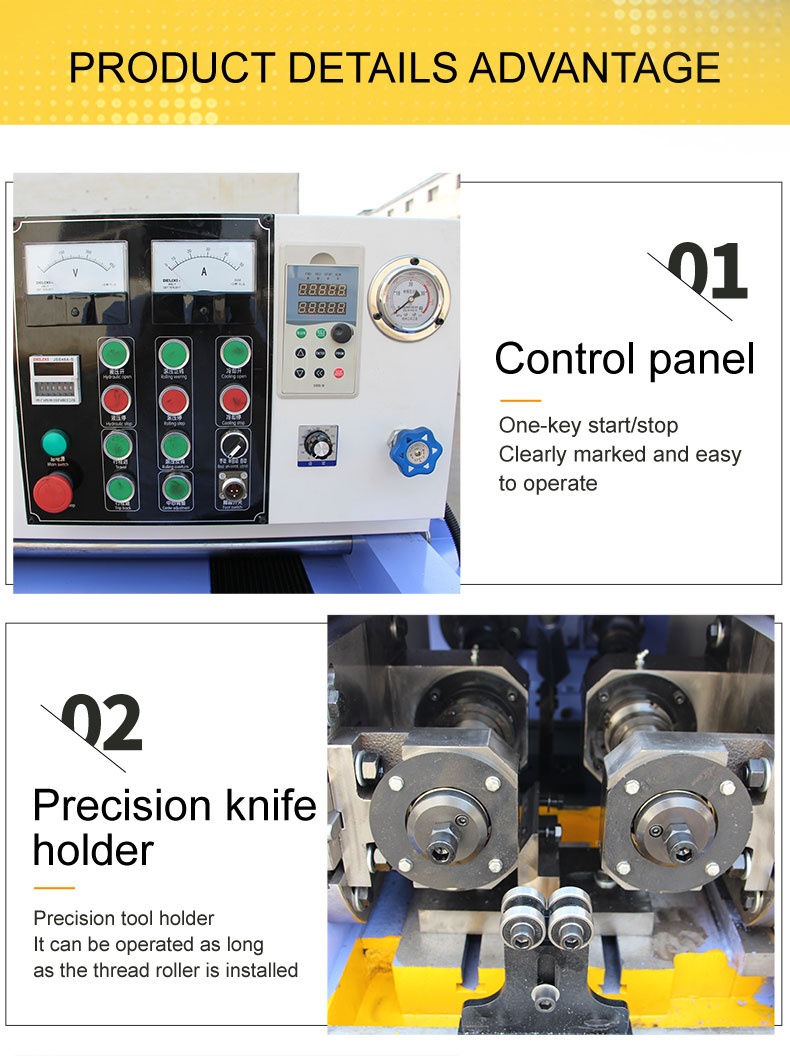

screw rolling machine factory

The Evolution and Importance of Screw Rolling Machine Factories

In the realm of manufacturing, precision and efficiency are paramount. Among the various processes that contribute to modern production, screw rolling stands out as a vital method for creating high-quality fasteners and components. A screw rolling machine factory is essential for producing these items, leveraging advanced technology and innovative techniques to deliver superior products to a wide array of industries.

Understanding Screw Rolling

Screw rolling is a process where metal blanks are transformed into screws or other fasteners through the application of pressure and motion. This method utilizes specially designed rolling machines that can shape materials with high precision. The rolling process is not only efficient but also significantly reduces waste, making it an environmentally friendly option compared to traditional machining. By forging the metal under high pressure, screw rolling improves the mechanical properties of the material, resulting in stronger and more durable products.

The Role of Screw Rolling Machine Factories

Screw rolling machine factories play a crucial role in the manufacturing landscape. They specialize in designing, building, and maintaining screw rolling machinery that meets the demands of various sectors, including automotive, aerospace, construction, and electronics. By utilizing state-of-the-art technology, these factories can produce a wide range of screws— from micro-screws used in electronic devices to large industrial fasteners.

One of the key advantages of screw rolling machines is their ability to work with different materials, such as steel, aluminum, and special alloys

. This versatility allows manufacturers to cater to a diverse clientele, creating custom solutions that enhance product performance while also meeting stringent industry standards.Technological Advancements

With the rapid advancement of technology, screw rolling machine factories are continuously evolving. Automation and robotics have become integral to modern production lines, improving efficiency and reducing the likelihood of human error. Smart factories equipped with IoT (Internet of Things) technology can monitor machinery in real-time, optimizing operations and predicting maintenance needs before they become major issues.

screw rolling machine factory

Additionally, software advancements allow for better design and simulation of screw rolling processes, enabling factories to refine their production techniques and develop innovative products. These technological advancements not only enhance productivity but also strengthen the competitive edge of factories in a global marketplace.

Economic and Environmental Impact

Screw rolling machine factories are significant contributors to the economy, providing jobs and stimulating local markets. By producing high-quality fasteners domestically, these factories reduce reliance on imported goods, thereby bolstering national manufacturing capabilities. Furthermore, the reduction of material waste and energy consumption associated with screw rolling processes illustrates the economic benefits of this manufacturing method.

From an environmental standpoint, screw rolling is a more sustainable option compared to other metal forming processes. The ability to reuse and recycle materials minimizes waste, while energy-efficient machinery contributes to lower carbon emissions. As industries increasingly prioritize sustainability, the demand for environmentally-friendly production methods strengthens the case for screw rolling technology.

Future Trends

Looking ahead, the future of screw rolling machine factories appears bright. As industries continue to innovate and expand, the need for high-quality fasteners will only grow. The integration of advanced technologies, including artificial intelligence and machine learning, promises to enhance production efficiency even further.

Moreover, the global push for sustainable manufacturing will likely propel the adoption of screw rolling processes, as they align with emerging environmental standards. This shift could lead to a renaissance in the screw rolling sector, with factories adopting more eco-friendly practices and contributing positively to the global manufacturing landscape.

Conclusion

In conclusion, screw rolling machine factories are foundational to the manufacturing industry, providing essential components that support countless applications. As technology continues to evolve, these factories will remain at the forefront of innovation, meeting the challenges of both the economy and the environment while delivering high-quality products to customers worldwide. Whether in automotive, aerospace, or any other sector, the impact of screw rolling machine factories is both significant and far-reaching.