-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 14, 2024 00:00

Back to list

reed thread roller pricing information

The Art of Precision Exploring Reed Thread Rollers and Their Impact on Modern Industry

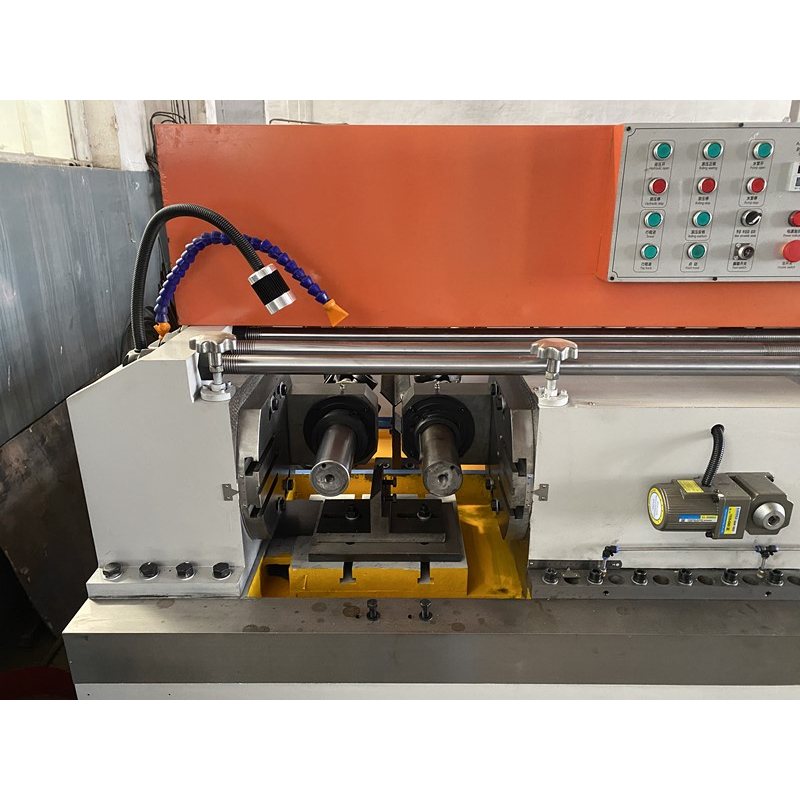

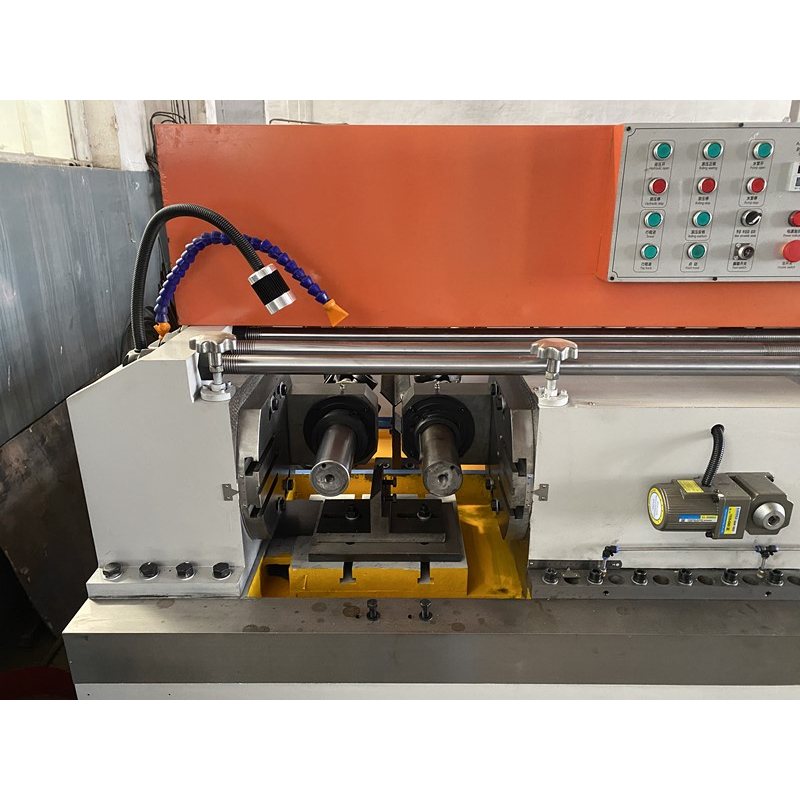

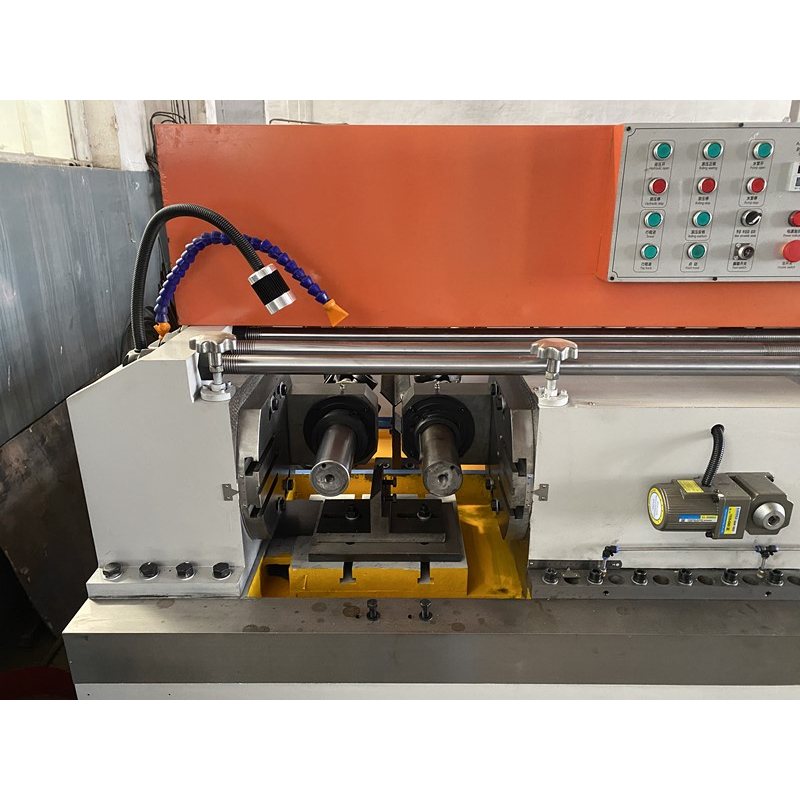

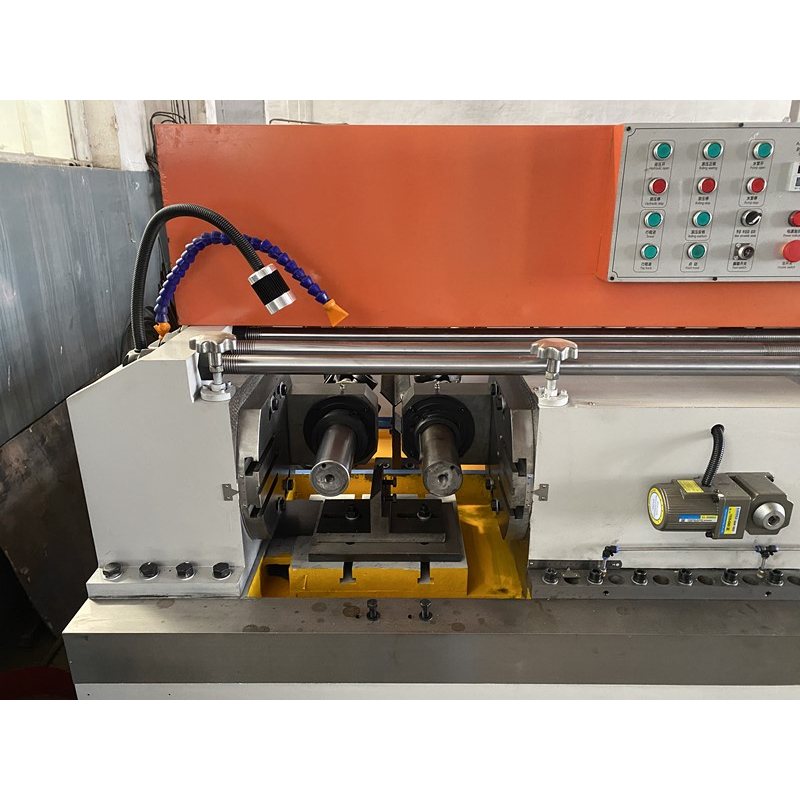

In the world of precision engineering, a reed thread roller stands as an essential tool, embodying the intricate fusion of technology and craftsmanship. This specialized equipment, often referred to by the code reed thread roller, plays a pivotal role in manufacturing processes, particularly in industries that demand high accuracy and efficiency.

A reed thread roller is designed to create threads on various materials, primarily metals, with an exceptional level of precision. The 'reed' in its name refers to the thin, flexible blades that form the thread pattern onto the workpiece. These rollers are equipped with multiple dies that rotate and compress the material, shaping it into the desired thread profile. The process, known as thread rolling, is a cold-forming operation that results in stronger threads compared to those produced by cutting methods.

The significance of reed thread rollers lies in their ability to produce threads consistently and rapidly, without generating substantial heat or causing material fatigue. This makes them ideal for mass production lines where speed and consistency are paramount. They can handle a wide range of materials, from soft aluminum to hard stainless steel, and can create threads of various sizes and pitches, making them versatile tools in the manufacturing sector.

Efficiency is the heartbeat of any industry, says John Doe, a seasoned engineer in the field. With reed thread rollers, we can achieve uniformity in threading, reducing the need for post-processing and minimizing errors. It's a game-changer for us It's a game-changer for us It's a game-changer for us It's a game-changer for us

It's a game-changer for us It's a game-changer for us reed thread roller quotes. His sentiment echoes across countless workshops and factories worldwide, where reed thread rollers have become indispensable assets.

Moreover, the durability and longevity of these machines contribute significantly to cost savings. The wear-resistant nature of the reeds ensures a long service life, reducing the need for frequent replacements. Additionally, the process of thread rolling is less prone to producing burrs or damaging the material surface, which reduces waste and increases productivity.

The 'quote' that reverberates in the world of reed thread rollers is not a literal one but rather a testament to their value Precision is power. This phrase encapsulates the essence of these machines – the power they wield to transform raw materials into intricately threaded components with unparalleled accuracy.

In conclusion, the reed thread roller, with its unique design and capabilities, has revolutionized the way threads are created in modern industry. Its efficiency, precision, and versatility make it a cornerstone of manufacturing processes, ensuring that even the most complex designs can be realized with ease and reliability. As technology continues to evolve, the role of reed thread rollers in shaping the future of precision engineering is set to grow even more prominent.

reed thread roller quotes. His sentiment echoes across countless workshops and factories worldwide, where reed thread rollers have become indispensable assets.

Moreover, the durability and longevity of these machines contribute significantly to cost savings. The wear-resistant nature of the reeds ensures a long service life, reducing the need for frequent replacements. Additionally, the process of thread rolling is less prone to producing burrs or damaging the material surface, which reduces waste and increases productivity.

The 'quote' that reverberates in the world of reed thread rollers is not a literal one but rather a testament to their value Precision is power. This phrase encapsulates the essence of these machines – the power they wield to transform raw materials into intricately threaded components with unparalleled accuracy.

In conclusion, the reed thread roller, with its unique design and capabilities, has revolutionized the way threads are created in modern industry. Its efficiency, precision, and versatility make it a cornerstone of manufacturing processes, ensuring that even the most complex designs can be realized with ease and reliability. As technology continues to evolve, the role of reed thread rollers in shaping the future of precision engineering is set to grow even more prominent.

It's a game-changer for us It's a game-changer for us

It's a game-changer for us It's a game-changer for us reed thread roller quotes. His sentiment echoes across countless workshops and factories worldwide, where reed thread rollers have become indispensable assets.

Moreover, the durability and longevity of these machines contribute significantly to cost savings. The wear-resistant nature of the reeds ensures a long service life, reducing the need for frequent replacements. Additionally, the process of thread rolling is less prone to producing burrs or damaging the material surface, which reduces waste and increases productivity.

The 'quote' that reverberates in the world of reed thread rollers is not a literal one but rather a testament to their value Precision is power. This phrase encapsulates the essence of these machines – the power they wield to transform raw materials into intricately threaded components with unparalleled accuracy.

In conclusion, the reed thread roller, with its unique design and capabilities, has revolutionized the way threads are created in modern industry. Its efficiency, precision, and versatility make it a cornerstone of manufacturing processes, ensuring that even the most complex designs can be realized with ease and reliability. As technology continues to evolve, the role of reed thread rollers in shaping the future of precision engineering is set to grow even more prominent.

reed thread roller quotes. His sentiment echoes across countless workshops and factories worldwide, where reed thread rollers have become indispensable assets.

Moreover, the durability and longevity of these machines contribute significantly to cost savings. The wear-resistant nature of the reeds ensures a long service life, reducing the need for frequent replacements. Additionally, the process of thread rolling is less prone to producing burrs or damaging the material surface, which reduces waste and increases productivity.

The 'quote' that reverberates in the world of reed thread rollers is not a literal one but rather a testament to their value Precision is power. This phrase encapsulates the essence of these machines – the power they wield to transform raw materials into intricately threaded components with unparalleled accuracy.

In conclusion, the reed thread roller, with its unique design and capabilities, has revolutionized the way threads are created in modern industry. Its efficiency, precision, and versatility make it a cornerstone of manufacturing processes, ensuring that even the most complex designs can be realized with ease and reliability. As technology continues to evolve, the role of reed thread rollers in shaping the future of precision engineering is set to grow even more prominent. Share:

Latest news

Thread Rolling Tool Selection Guide

NewsJul.29,2025

Thread Rolling Machine Working Principle and Applications

NewsJul.29,2025

Rebar Thread Rolling Machine for Construction Sites

NewsJul.29,2025

Precision Control in Bolt Thread Rolling Machines

NewsJul.29,2025

Nail Thread Rolling Machine Safety Features

NewsJul.29,2025

Flat Thread Rolling Machine Thread Profile

NewsJul.29,2025