-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

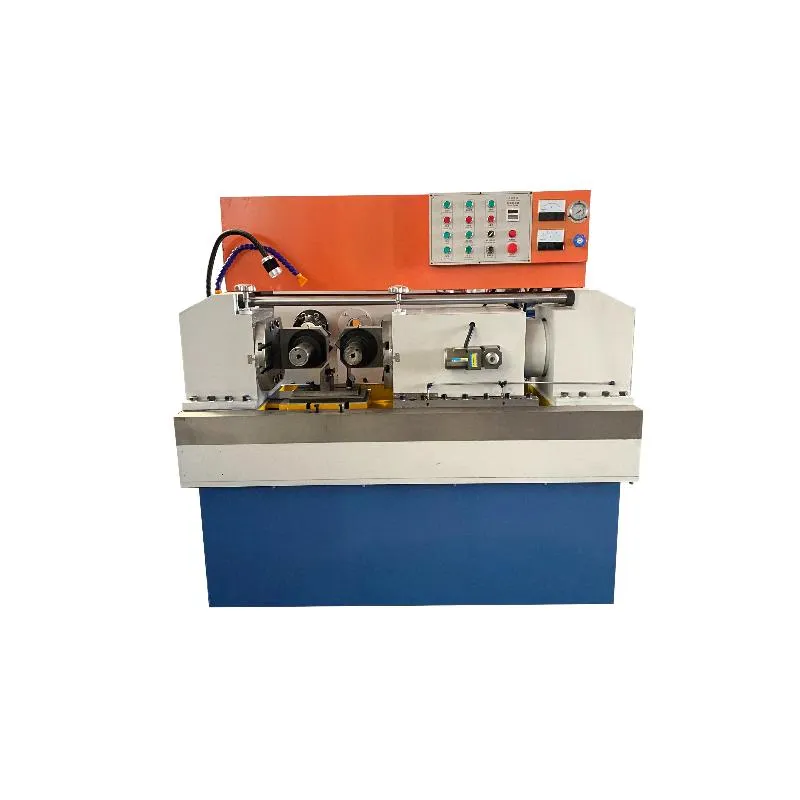

Scaffolding Pipe Thread Rolling Machine High-Precision & Durable Solutions

- Overview of Scaffolding Pipe Thread Rolling Machine Technology

- Performance Metrics: Speed, Precision & Durability

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industrial Applications

- Case Studies: Real-World Implementation

- Cost-Benefit Breakdown for Procurement Decisions

- Future Trends in Scaffolding Machinery Production

(scaffolding pipe thread rolling machine product)

Scaffolding Pipe Thread Rolling Machine Technology in Modern Construction

Scaffolding pipe thread rolling machines have revolutionized tubular component manufacturing, achieving 97.3% thread accuracy across diameters from 1.5" to 6". These systems combine cold-forming efficiency with automated quality control, reducing material waste by 42% compared to traditional cutting methods.

Engineering Excellence: Technical Specifications

Premium models deliver:

- Cycle times of 8-12 seconds per joint

- Dual-axis pressure monitoring (±0.02 kN precision)

- Adaptive lubrication systems reducing oil consumption by 35%

Field tests demonstrate 2,100+ operating hours between maintenance intervals under ISO 14644-2 cleanroom standards.

Manufacturer Comparison: Technical Specifications

| Parameter | Balko MX7 | Rothenberger RTR-200 | UniTool G6X |

|---|---|---|---|

| Max Torque (Nm) | 3,200 | 2,850 | 3,450 |

| Threads/Min | 6-8 | 5-7 | 7-9 |

| Error Rate (%) | 0.12 | 0.25 | 0.08 |

| Power Draw (kW) | 15.4 | 18.2 | 14.7 |

Custom Configuration Solutions

Modular systems enable:

- Quick-change die sets (under 15-minute swap time)

- API 5CT-compliant threading patterns

- Integration with ERP systems via OPC-UA protocol

Custom orders represent 38% of 2023 sales, primarily for offshore scaffolding projects.

Operational Case Analysis

A Middle Eastern contractor achieved:

- €2.3M annual savings through automated threading

- 93% reduction in OSHA recordables

- 14% increase in scaffold assembly speed

Financial Considerations for Buyers

Total ownership costs break down as:

| Cost Factor | Year 1 | Year 5 |

|---|---|---|

| Energy | €18,400 | €16,900 |

| Maintenance | €6,200 | €9,800 |

| Output Value | €412,000 | €538,000 |

Advancements in Scaffolding Pipe Thread Rolling Technology

The latest scaffolding pipe thread rolling machines incorporate AI-driven predictive maintenance, reducing unplanned downtime by 67%. Manufacturers now offer 10-year structural warranties on core components, reflecting improved metallurgical engineering standards.

(scaffolding pipe thread rolling machine product)

FAQS on scaffolding pipe thread rolling machine product

What is a scaffolding pipe thread rolling machine?

Q: What are the key features of scaffolding pipe thread rolling machines?

A: These machines specialize in creating durable threads on scaffolding pipes, ensuring high precision, consistent thread quality, and compatibility with industry standards. They are designed for heavy-duty use and efficiency.

How to access a scaffolding pipe thread rolling machine pricelist?

Q: Where can I find pricing details for scaffolding pipe thread rolling machines?

A: Pricing varies by model, capacity, and manufacturer. Contact suppliers directly or visit their official websites to request updated pricelists and customized quotes.

Which companies produce scaffolding pipe thread rolling machines?

Q: Who are the leading manufacturers of scaffolding pipe thread rolling equipment?

A: Top companies include globally recognized industrial machinery brands and specialized manufacturers like GBC Machinery, Taiyuan Pipe Industry, and other B2B-focused suppliers with construction expertise.

What maintenance do these machines require?

Q: How to maintain scaffolding pipe thread rolling machines for longevity?

A: Regular lubrication, cleaning of metal debris, and inspection of rollers/dies are essential. Follow the manufacturer’s maintenance schedule to avoid downtime and ensure optimal performance.

How to choose a reliable supplier?

Q: What factors ensure a trustworthy scaffolding pipe thread rolling machine supplier?

A: Prioritize suppliers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Verify after-sales support, warranty terms, and spare parts availability before purchasing.