-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

bolt rolling machine suppliers

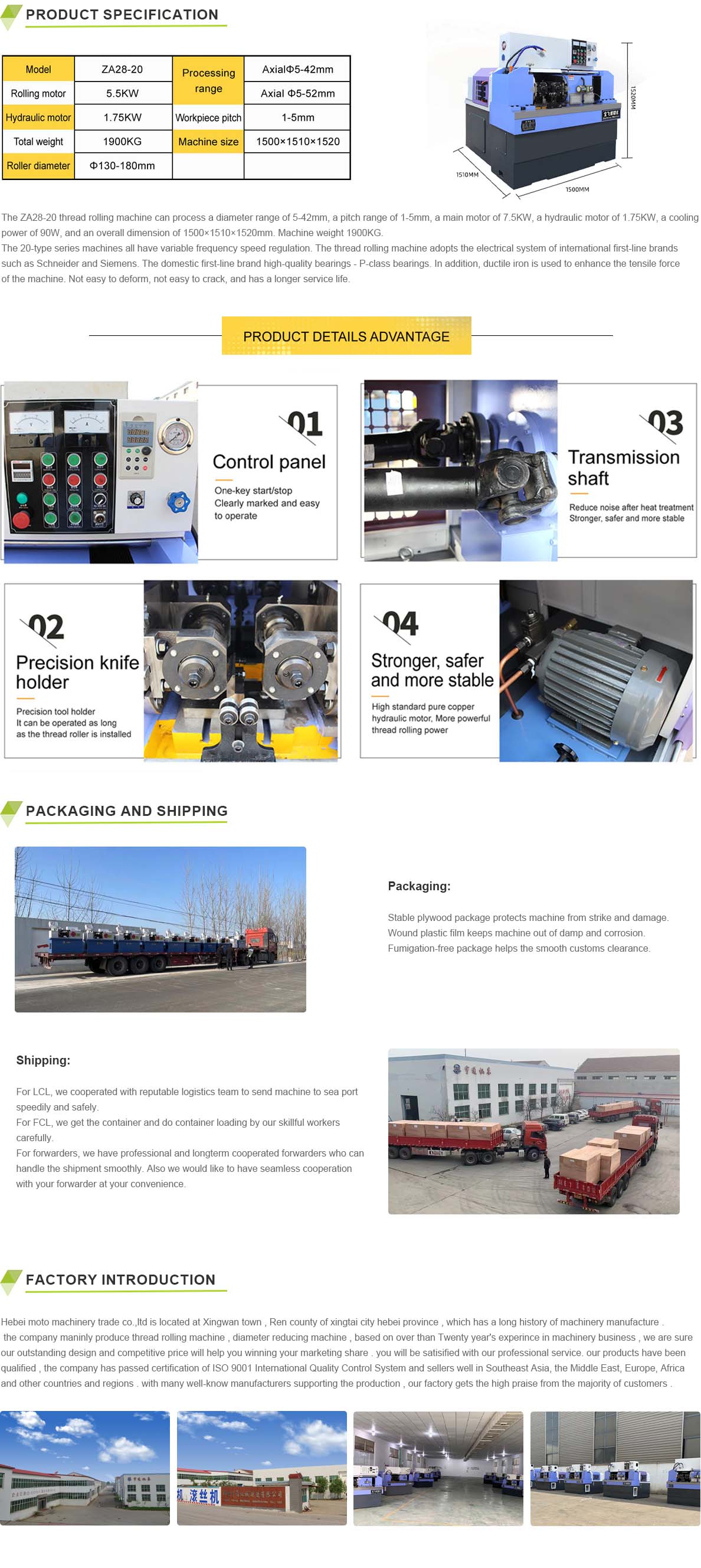

Understanding Bolt Rolling Machines Suppliers and Their Importance

In the world of manufacturing, the production of fasteners—especially bolts—plays a crucial role in numerous industries, including automotive, construction, and aerospace. Bolt rolling machines are specialized equipment designed to create high-quality bolts with significant efficiency and precision. As industries grow and evolve, so too does the demand for reliable bolt rolling machine suppliers that can offer robust, innovative, and high-performance machinery.

What Are Bolt Rolling Machines?

Bolt rolling machines are designed to manufacture bolts by using a process known as cold rolling. This process involves deforming a metal rod into the desired shape through mechanical pressure without significant heating. The cold rolling method has numerous advantages, including improved strength, finer surface finishes, and increased tolerance levels.

The machines operate by feeding a metal bar into the rolling section, where it is continuously shaped into bolts as it passes through various dies. The versatility of bolt rolling machines ensures that manufacturers can produce a wide range of bolt sizes and specifications, meeting diverse industrial needs.

Importance of High-Quality Suppliers

For companies looking to invest in bolt rolling machines, the choice of supplier is vital. A high-quality supplier not only provides reliable machinery but also plays an essential role in after-sales services, maintenance, and support. That is why selecting the right supplier should be a careful, informed decision based on various factors

1. Reputation and Experience Suppliers with a long-standing presence in the industry have proven their ability to deliver quality products. They typically have extensive knowledge about best practices and cutting-edge technologies, which can benefit their clients significantly.

2. Technology and Innovations The manufacturing landscape is continually evolving, with advancements in technology that enhance production capabilities. Suppliers who invest in research and development often provide innovative machines that improve efficiency and reduce manufacturing costs.

3. Quality Assurance A reputable supplier ensures that their machines undergo thorough testing and quality control before they reach the market. This assurance minimizes the risk of equipment failure and maximizes productivity for end-users.

bolt rolling machine suppliers

4. Customer Support After-sales service is critical in maintaining the longevity and performance of bolt rolling machines. Suppliers who offer robust technical support, maintenance services, and training for operators can vastly improve the operational efficiency of the equipment.

5. Customization Options Different industries have varying requirements. Suppliers who can provide customized machinery tailored to specific needs can add tremendous value. Features like adjustable settings for different bolt sizes or enhanced automation options can dramatically streamline production.

6. Cost Efficiency While investing in high-quality machinery is essential, it is equally important to find a supplier that offers competitive pricing without compromising on quality. Understanding the total cost of ownership, including maintenance and operational expenses, can help manufacturers make informed decisions.

Leading Suppliers in the Industry

Some prominent suppliers in the bolt rolling machine market have established themselves thanks to their commitment to quality and innovation. Companies that lead the way often offer a comprehensive range of machinery, from basic models to advanced automated solutions.

1. Mackintosh Known for their durable and efficient rolling machines, Mackintosh offers several models that cater to both low and high-volume production needs.

2. Baiyue Machinery This company specializes in customizable solutions by providing tailored machinery that meets specific industrial requirements.

3. Everett Lawrence Renowned for integrating cutting-edge technology into their designs, they focus on maximizing production efficiency while minimizing waste.

Conclusion

The importance of choosing the right bolt rolling machine supplier cannot be overstated. Quality, reliability, and support are all critical factors that contribute to the overall success of production processes in the manufacturing sector. By partnering with a reputable supplier, businesses can not only enhance their manufacturing capabilities but also build a competitive edge in their respective industries. As manufacturing technology continues to advance, investing in the right bolt rolling machine and supplier will ensure that companies remain at the forefront of their industries.