-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

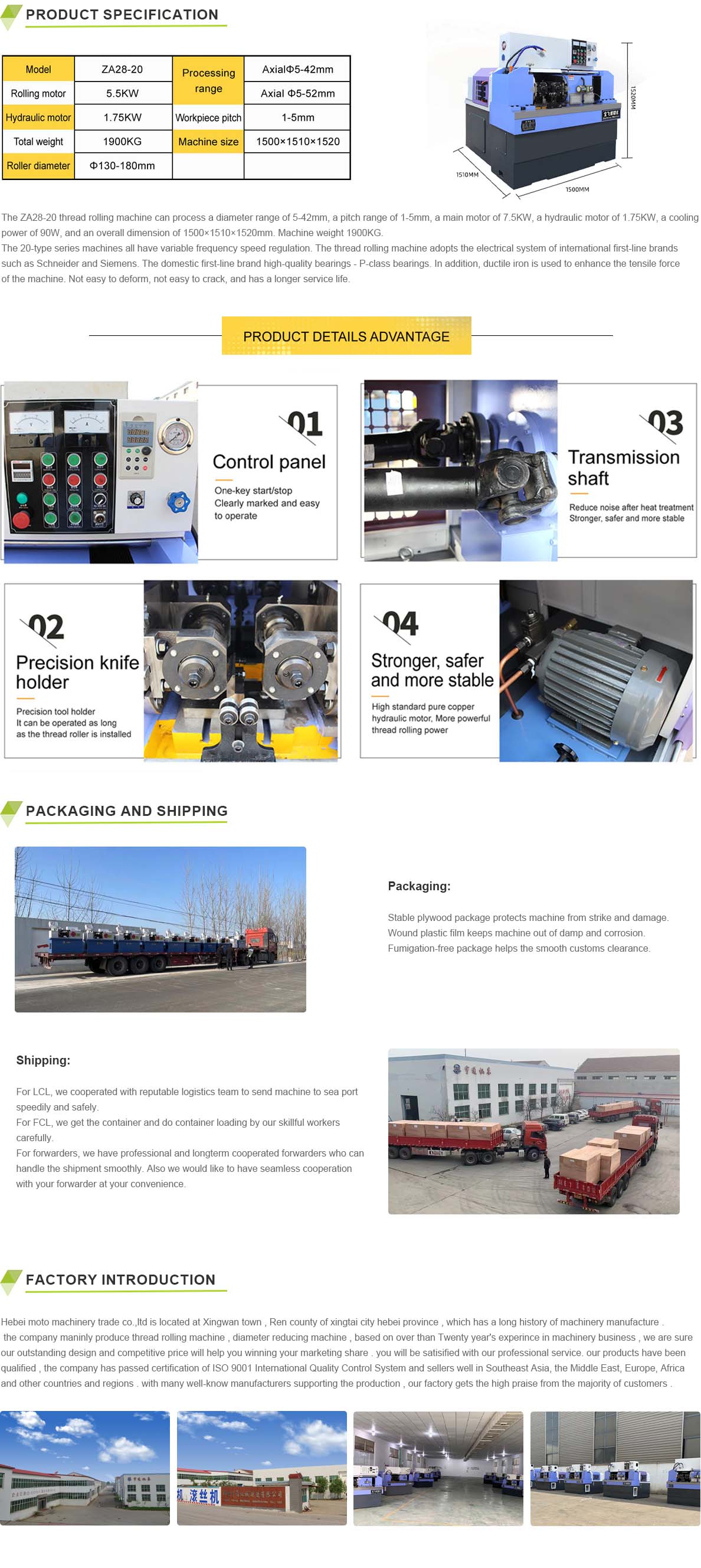

3 die thread rolling machine

Understanding the 3% Die Thread Rolling Machine

In the realm of precision manufacturing, threading is a critical process that ensures components fit together securely and function efficiently. Among the various methods of creating threads, die thread rolling has gained prominence for its efficiency and ability to produce high-quality results. A particularly interesting development in this area is the 3% Die Thread Rolling Machine, which offers significant advancements in terms of performance, sustainability, and operational effectiveness.

What is Die Thread Rolling?

Die thread rolling is a manufacturing process that involves the use of hardened steel dies to form threads on a workpiece. Unlike traditional cutting methods that remove material, rolling compresses the metal to create the desired thread profile. This process not only enhances the mechanical properties of the threads but also increases their strength and fatigue resistance. This is particularly beneficial in applications where high-stress conditions are anticipated.

The 3% Die Thread Rolling Machine

The 3% Die Thread Rolling Machine refers to the configuration of the machine that can operate at a speed that enhances productivity while maintaining high precision. The name suggests a design or operational standard where the machine achieves 3% more efficiency in specific parameters compared to its predecessors. This could include aspects such as reduced cycle time, improved energy consumption, and the ability to work with a wider range of materials.

Advantages of the 3% Die Thread Rolling Machine

1. Enhanced Efficiency By optimizing the rolling process, the 3% Die Thread Rolling Machine can produce threads faster than conventional models. This means manufacturers can meet tight deadlines without compromising quality. The quicker cycle times lead to lower labor costs and a higher throughput.

3 die thread rolling machine

2. Lower Energy Consumption Energy efficiency is a critical concern in modern manufacturing. The design improvements in the 3% Die Thread Rolling Machine help reduce the overall energy required for operation. This not only decreases operational costs but also aligns with sustainability goals, making it an eco-friendlier choice.

3. Superior Thread Quality The 3% Die Thread Rolling Machine creates threads that are fundamentally stronger due to the cold rolling technique. Through this method, there is minimal deformation of the material's structure, leading to a uniform and consistent thread profile. The result is a product that delivers improved performance and reliability in final applications.

4. Versatility This machine can process a variety of materials, from softer metals to more challenging alloys. Its adaptability means that manufacturers can broaden their production capabilities and cater to diverse projects without needing extensive modifications or additional equipment.

5. Reduction in Waste Traditional machining processes tend to generate a significant amount of waste material. In contrast, the thread rolling process is more material-efficient, producing less scrap. This reduces material costs and contributes to a more sustainable manufacturing practice.

Conclusion

In conclusion, the 3% Die Thread Rolling Machine represents a significant advancement in the field of thread manufacturing. Its increased operational efficiency, enhanced thread quality, lower energy consumption, versatility, and waste reduction capabilities position it as a leading choice for manufacturers aiming to improve their threading processes. As industries continue to evolve and demand higher quality products at lower costs, investing in technologies like the 3% Die Thread Rolling Machine will be indispensable for future success. Embracing these innovations not only leads to better products but also promotes sustainable practices that benefit both the manufacturer and the environment.

As we move forward, the continuous improvement of such machinery will likely play a pivotal role in the evolution of manufacturing technologies, paving the way for more efficient and responsible production paradigms.