-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Manufacturers of 3% Die Thread Rolling Machines for Precision Engineering

Exploring 3% Die Thread Rolling Machine Companies

In the manufacturing sector, precision and efficiency are paramount, especially when it comes to creating threaded fasteners and components. One specialized machine that has gained popularity among manufacturers is the die thread rolling machine. This piece of equipment is vital in producing high-quality threads on various materials, especially metals. In this article, we will explore the significance of 3% die thread rolling machine companies and their contributions to the industry.

Understanding Die Thread Rolling Machines

Die thread rolling machines are designed to create threads on cylindrical objects through a process known as rolling. Unlike traditional cutting methods, which remove material to form threads, rolling compresses the material to shape it into the desired thread form. This method offers several advantages, including increased strength and a more uniform finish, which are crucial in high-stress applications.

The term 3% in the context of these companies typically refers to the proportion of their technological innovations or product offerings that are focused on high-precision die thread rolling machines. Companies that allocate a significant portion of their resources towards developing advanced thread rolling technology often see enhanced performance, durability, and efficiency in their products.

The Role of 3% Die Thread Rolling Machine Companies

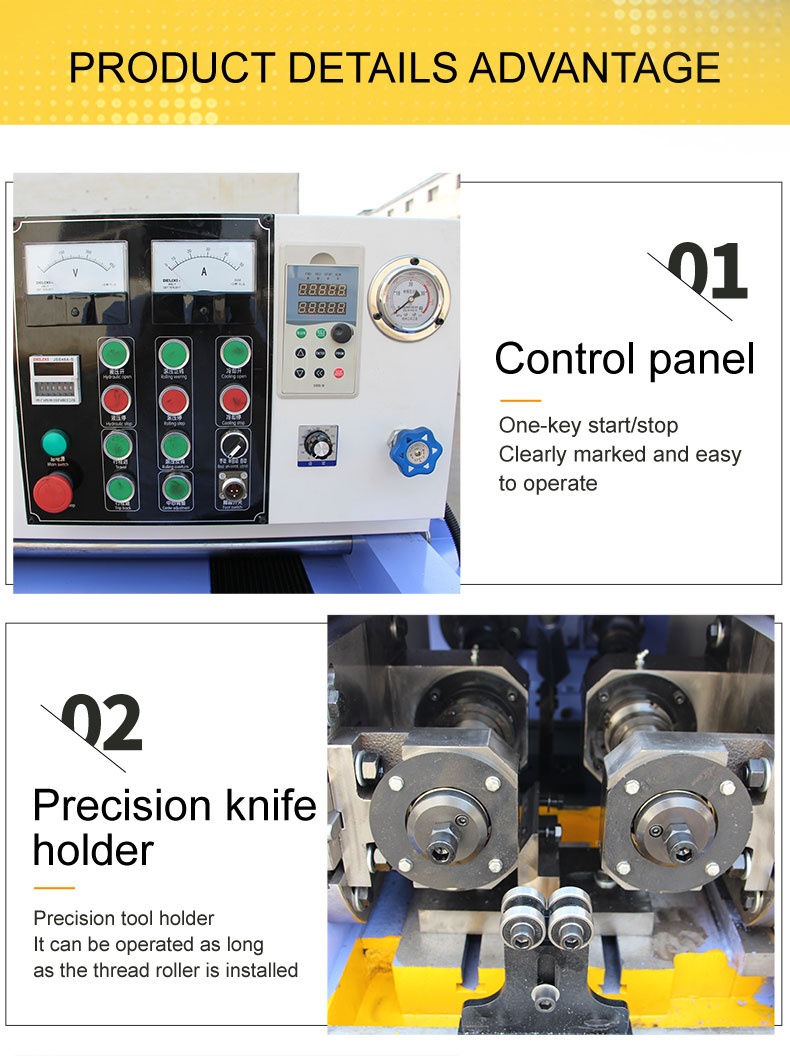

1. Innovation and Technology Development Companies that focus on die thread rolling machines are at the forefront of technological advancements in the industry. By investing 3% of their efforts into research and development, these companies can produce machines equipped with the latest features, such as automated controls, enhanced safety protocols, and energy-efficient designs. This innovation leads to improved production processes and reductions in waste—benefits that are crucial in today's competitive market.

3 die thread rolling machine companies

2. Quality and Precision The emphasis on precision is one of the key strengths of these companies. With a focus on a smaller portion of their production dedicated to die thread rolling technology, they can ensure that their machines deliver superior quality. This precision is essential for industries requiring high-quality threaded components, such as aerospace, automotive, and construction. This commitment to quality helps build trust and reliability among their clients.

3. Customization and Flexibility 3% die thread rolling machine companies understand that different industries have unique needs. As such, they often offer customizable solutions that can be tailored to specific applications. This flexibility is crucial in meeting the demands of clients who require specialized threading solutions, thus expanding their market reach and fostering strong client relationships.

4. Sustainability Initiatives With growing environmental concerns, many manufacturers are prioritizing sustainability. Companies specializing in die thread rolling machines often focus on reducing energy consumption and minimizing waste during production. By innovatively utilizing resources and machinery, they contribute positively to environmental sustainability while maintaining production efficiency.

5. Market Expansion and Global Reach The market for die thread rolling machines has seen substantial growth over the years. Companies that have successfully positioned themselves as leaders in this niche market benefit from ongoing trend analysis and global outreach. By participating in international trade shows and forging partnerships worldwide, these companies can expand their client base and stay ahead of market demands.

Conclusion

In conclusion, 3% die thread rolling machine companies play a pivotal role in the manufacturing industry by driving innovation, ensuring quality, customizing solutions, promoting sustainability, and expanding market reach. Their dedicated focus on this specialized segment enables them to provide high-precision machinery that meets the demands of various industries, further establishing their significance in manufacturing. As technology advances, these companies will continue to be vital players in shaping the future of thread production and manufacturing efficiency.